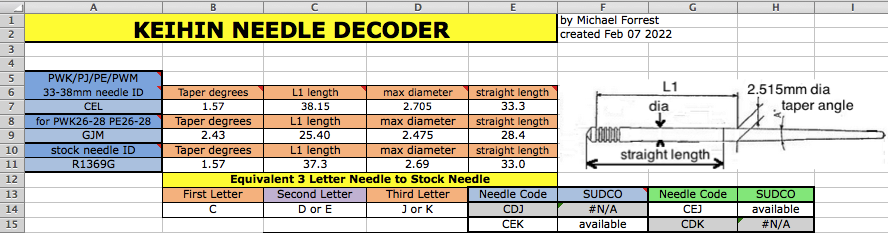

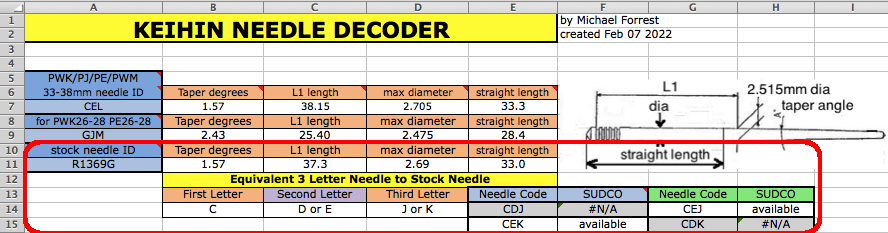

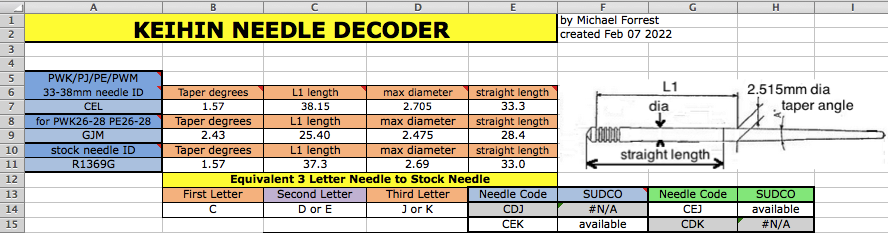

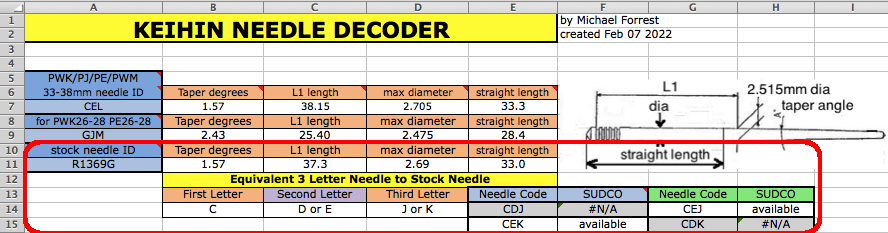

Keihin Needle Decoder

Excel Spreadsheet Functions

It breaks the needle codes to tell you the needle taper angle, L1 length, shaft diameter, and straight length to taper start.

This helps if you want a different taper angle or straight shaft length. For the 3 letter needles for the 33-38mm PWK/PJ/PE/PWM carbs it also shows if what you want is available from SUDCO (whose inventory is basically the same as Jets-R-Us but I have never had any quality issues when buying from SUDCO so I prefer to buy from them. Email Chad at chadt@sudco.com)

As with all my spreadsheets, the data entry cells are the light blue ones. Just put the pointer over the cell, click, then type in the data, then press the Enter key.

Straight Shaft Length

First you need to try different needle clip positions to find which position gives the best off idle transition from closed throttle to 1/4 throttle. You should mark your throttle body and handgrip with White-Out to see the 1/4 throttle position while riding. Gradually open the throttle while noting the engine response. It's normal to have a lean zone just off closed throttle but beyond that you should have normal power. If the best transition power requires the needle clip to be at the first or last position for that to heppen then you need a needle with a different straight shaft length. If you are at clip position #1 then get a needle with a 2mm longer straight length. If it is at #5 position then get a needle with a 2mm shorter straight length. It is best to not go by the L1 length (I'll explain later).

Needle Taper Angle

A too-lean needle will cause engine bog when cracking the throttle open from a mid throttle position. A too-rich needle will give an inconsistent exhaust note at mid throttle and then accelerate good when cracking the throttle open. A richer needle will have more taper angle, and a leaner needle will have less taper angle. People erroneously try to make up for incorrect taper angle by changing the clip position but then that screws up the transition power off idle. The correct way is selecting a needle with a better taper angle.

Needle Diameter

About half of the gasoline going to the engine at idle comes from the needle/needle-jet space. The way to tell if that clearance is correct is by analyzing the slide open distance at idle. If the slide is less than 11% open at idle then probably the needle clearance is too big and you need a fatter needle or skinnier needle jet. If the slide is more than 11% open at idle then probably the needle clearance is too small and you need a skinnier needle. The 11% only applies to reed valved engines. Click here to read more.

Engines 200cc or larger eventually wear out the needle jet to have a larger hole due to the needle vibrating with engine vibrations (unless it has an extra balance shaft). If you don't want to replace that needle jet (often they are just a press fit) then you need a fatter needle to make up for it.

Carb Sizes

This spreadsheet is about the needles for the medium and large size Keihin carbs. The area below that's circled in red is about decoding the needles for their 33mm and larger carbs. The 3 letter equivalent needle is listed at B14 to D14. In this case the 2nd and 3rd listing shows two letters each. That is because the original measurement falls between two needles of the 3 letter kind. To the right of that is displayed the 3 letter code needles that are available from SUDCO. To see the exact measurements of each one just enter the same code into A7 to see it's specs from B7 to E7. Select a couple you want to try and see if SUDCO has them ready ($13.25 each).

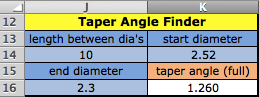

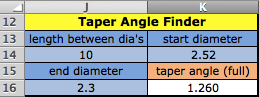

DIY Taper Angle Finder

Some aftermarket needles come from disreputable sources that have the shitz to claim they are "original" but they aren't and sometimes they are far off. So it's best to measure the needle yourself and use the mini calculator at J12 to K16 to see what its real taper angle is. Just place two black marks on the needle about 10 or more mm apart, measure their distance, and then measure the needle width at each mark and put all that data into the calculator to see what its angle is at K16.

Multiple Taper Needles

Dual or Triple taper needles don't have single taper equivalents and it's silly for anyone to imply this. It's best to just buy my $20 Jetting Calculator which will let you virtually try other needles (single, dual, and triple taper) whose data is in my calculator as well as different slide cutaway heights. This page describes how to use the calculator for Keihin (although it also is for Mikuni and Dellorto).

Click here to download this free Excel spreadsheet. Click here for a list of all my 2 stroke calculators.

Go to this page to see a list of my best videos on 2 stroke topics.

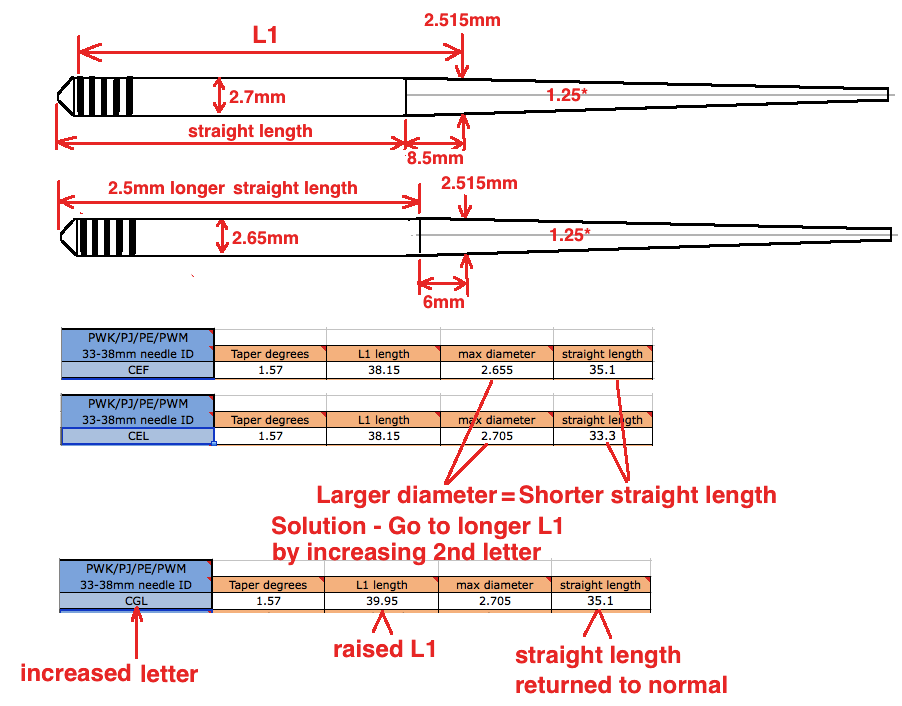

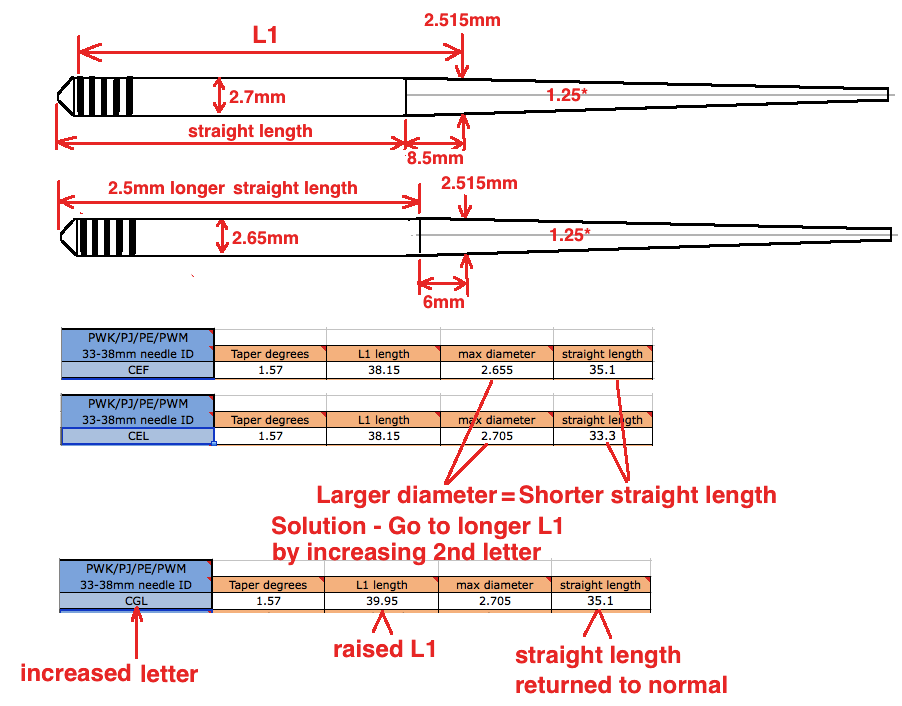

L1 Expose

An L1 comparison between needles has no significance if the needles are of different diameters. In the example below the straight shaft length changed by 2.5mm when the shaft diameter changed from 2.7 to 2.65mm. It's the distance to the beginning of the taper that is a universally important measurement when dealing with needles, not the L1 distance which is basically a manufacturing spec.

HOME

|