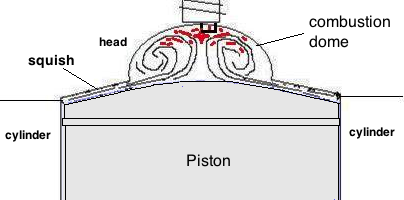

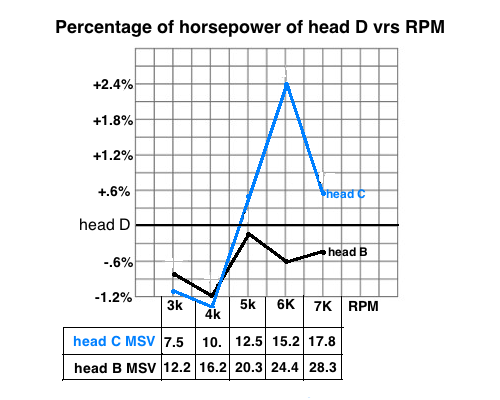

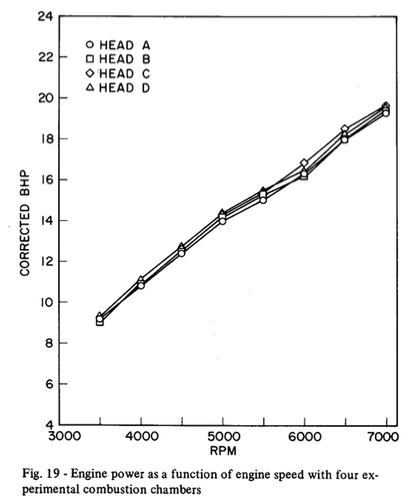

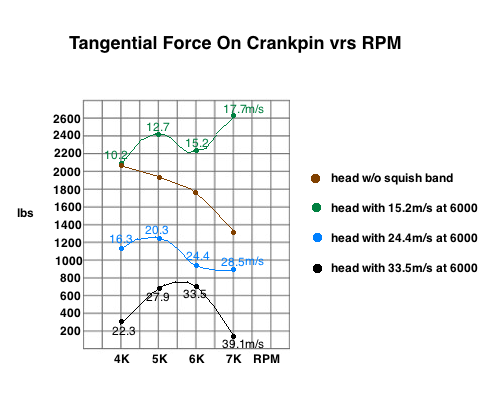

(source) In order to force the mixture at the margins of the chamber towards the advancing flame front, engines tend to take advantage of the squish effect. The term ’squish’ refers to the thin part of the combustion chamber at the outside of the piston where the piston most closely approaches the head. The mixture is forced inwards at a velocity affected by various factors including the squish area and shape, engine stroke and engine speed. The reverse happens as the piston descends, with the enflamed volume being drawn out towards the margins of the chamber. Squish Band - Outer area of head that forces the unburned fuel air mix into the center chamber for combustion. The squish band angle is either parallel to the piston top or 1-2 degrees greater so that the inner part of the squish band has more clearance than the outer part. That is to lessen the increase in velocity at the inner area relative to the outer area. Squish Clearance - Vertical distance between top of piston and squish band. This distance should be small but not less than .5mm plus the amount the connecting rod and piston top expands with heat. This expansion amount is something around .3mm for 80cc, .4mm for 125cc, .5mm for 200cc, .6mm for 300cc, and .7mm for 450cc. Less squish clearance produces higher squish velocity. Maximum Squish Velocity (MSV) - The maximum velocity of the fuel mixture traveling across the squish band just before the piston reaches TDC. Usually measured in meters per second (m/s). The velocity increases with RPM so max RPM or peak power RPM is used for the calculations. TSR recommends 15-30m/s at maximum RPM. Gordon Blair said that the squish velocity needs to be between 15 and 20 m/s at the peak power RPM. With high octane gas or race gas you can use higher velocity because it's less likely to cause knocking when the squish clearance is at a minimum. Squish Band Surface Area - It varies from 30% - 60% of Bore area. The more area, the higher the squish velocity. (source) Modern squish designs consider the maximum squish velocity as one of the most important design parameters - one which ultimately controls all other squish related variables. The software programs from Blair, TSR and Bimotion all include this feature as part of the two stroke engine design data crunching - it's probably the most important head design program to own. This software makes it easy to design a combustion chamber to the correct maximum squish velocity, squish band thickness and width, based upon the engine's maximum operating RPM, octane requirement, engine displacement and other fixed mechanical parameters. It makes it possible to run as tight a squish thickness as possible without the onset of detonation. (source) The basic issue is there are hot spots in the combustion chamber- spark plug threads, microscopic bits of superheated carbon, sharp edges, and the metal around the exhaust port are all areas that will be hotter, and lead to more detonation. What advanced engine builders do is use the space between head and piston to create almost a bellows type event. They are squeezing the mixture, and using it to blow the mixture out into the main combustion chamber. This keeps mixture flowing past the hot spots, delaying detonation. Design and Simulation of Two Stroke Engines by Gordon Blair: Any technique which will assist the engine to run reliably at a high compression ratio on a given fuel must be studied thoroughly and, if possible, designed into the engine and experimentally tested. Squish action, easily obtained in the uncluttered cylinder head area of a conventional two-stroke engine, is one such technique. Squish velocity has a very pronounced effect on the rate of burning and heat release in two-stroke engines. High squish velocities lead to rapid burning characteristics and that rapid burning approaches the thermodynamic ideal of constant volume combustion. There is a price to be paid for this, evidenced by more rapid rates of pressure rise which can lead to an engine with more vibration and noise emanating from the combustion process. Further, if the burning is too rapid, too early, this can lead to high rates of NOx formation and slow and inefficient burning in the latter stages of combustion. One of the beneficial side effects of squish action is the possible reduction of detonation effects. The squish effect gives high turbulence characteristics in the end zones and, by inducing locally high squish velocities in the squish band, increases the convection coefficients for heat transfer. Should the cylinder walls be colder than the squished charge, the end zone gas temperature can be reduced to the point where detonation is avoided, even under high bmep and compression ratio conditions. For high-performance engines, such as those used for racing, the design of squish action must be carried out by a judicious combination of theory and experimentation. A useful design starting point for gasoline-fueled, loop-scavenged engines with central combustion chambers is to keep the maximum squish velocity between 15 and 20 m/s at the peak power engine speed. If the value is higher than that, the mass trapped in the end zones of the squish band may be sufficiently large and, with the faster flame front velocities engendered by a too-rapid squish action, may still induce detonation. However, if natural gas were the fuel for the engine, then squish velocities higher than 30 m/s would be advantageous to assist with the combustion of a fuel which is notoriously slow burning. As with most design procedures, a compromise is required, and that compromise is different depending on the performance requirements of the engine, and its fuel, over the entire speed and load range. Examples: (source) “my YZ250 had 1.8mm squish clearance after porting, setup for pump gas. I went to 1.0mm for race gas but it ran a bit flat, it messed me up and I had to get some thicker base gaskets to get it back to 1.3mm. And the RM144 came too tight at around 0.5mm and it would detonate plugs loose!” “I have come up with these results using Bimotion. Using mm measurements of the exhaust port I have come up with these results. (parallel squish to piston angle) SQUISH BAND 44% COMPRESSION TRAPPED 7.9 COMPRESSION SWEPT 12.9 SQUISH CLEARANCE 1.42mm MAX SQUISH VELOCITY 23.7 @10.8 BEFORE TDC TURBULENCE RATIO -.012 Seat of the pants; the bike is stronger, lost no top end, and very very crisp with regards to throttle response, it revs much much quicker.” So far most of what I’ve read about squish bands is that increasing squish velocity increases power but if you increase it too much it will cause detonation (by reducing the fuel mixture between the head and the very hot piston, letting it get too hot because there's less to heat up). The most commonly promoted squish velocity (at max RPM, not peak power RPM) has been 28m/sec. I found a research paper studying the various effects of different squish velocities that is rather eye-opening. I didn’t know that too much velocity actually slows down the combustion time by overtly dispersing the flame kernel. Also I had no idea that squish affects ignition timing requirements and loads on the rod and crank bearings. This data was obtained from a 2 stroke engine similar in dimensions to the KDX200 in that it has 199cc, 70mm bore, 184 duration exhaust, 126 duration transfers. The most alarming of this information is the high bearing loads that can result from having a squish velocity optimized for best power. In this study at 7000 RPM the crankpin load with the 15.2m/s head became 2.75 times that of the 24.4m/s head. And its pressure kept rising with RPM instead of dropping as is the case with the 24.4m/s head. No one likes replacing bearings so maybe we all should take a close look at this before we decide on any change to the head. The following is all from a research paper I bought (I can't legally make it fully available). Only thing lacking in this reseaarch is they don't say what the peak power RPM is. Normally a 200cc engine revs out to 9000 RPM and has peak power at 8100. Squish Velocity in the Combustion Chamber of a 2-Stroke Cycle Engine Avraham Ziv, Engineering Div., McCulloch Corp. Four cylinder heads with different combustion chamber dimensions were built to test the effect of various squish velocities on a number of engine parameters. All four heads had the same compression ratio, spark plug location, and squish height. The only variables were the combustion chamber dimensions that resulted in the estimated squish velocities. The engine size was 199cc with a 6.8:1 compression ratio. Values at 6000 RPM optimum squish velocity timing pressure rise head meters/sec peak HP BTDC psi/degree A 33.5 16.34 24* 31 B 24.4 16.34 20* 33 C 15.2 16.84 20* 21 D 0. 16.44 22* 26 horsepower RPM head A B C D 3000 7.34 7.11 7.08 7.17 4000 10.85 10.95 10.93 11.08 5000 14.00 14.21 14.30 14.23 6000 16.34 16.34 16.84 16.44 6500 17.99 18.04 18.51 18.18 7000 19.29 19.40 19.60 19.49  [The graph above is mine from the data. Head C's average power increase over a head w/o squish band from 5000 to 7000 is only 1.2%, a very minor amount, so I think this disproves the common concept that squish bands significantly increase engine power. It helps some, but probably mostly due to piston cooling. Below is a graph from the study that shows how minor the power differences are.]  It is an accepted theory that increased turbulence increases the burning rate (4); hence, one would expect to find the optimum spark timing to retard as the degree of turbulence increases. Fig. 13 indicates that the highest turbulence head (A) requires the most spark advance. The [optimum] spark timing retards as the degree of turbulence is reduced, coming to the most retard point with head C. It appears that, when the degree of turbulence increased beyond a certain point it begins to interfere with the formation of the initial nucleus of flame; hence, the high-turbulence head will require additional time to obtain optimum combustion. The rate of pressure rise and the maximum cylinder pressure will affect the loads exerted on engine structural components (wrist pin, connecting rod, crankshaft, bearings) and degree of smoothness of engine running. A very high rate of pressure rise will result in what is known as "engine roughness." Ricardo (2) set the threshold of the rate of pressure rise to start engine roughness to be between 30-35 psi/deg. The rate of pressure rise can be controlled by the shape of the combustion chamber and by the degree of turbulence. Using 30psi/deg for the threshold to start engine roughness it appears that engines with head C or D will run smoother than with head A or B. Gas pressure, inertia forces, and centrifugal forces induce bending and torsional stresses in the crankshaft. In this discussion, only bending stresses will be considered, and, in particular, those which are directly resulted from gas pressure. These loads are mainly a function of two variables: maximum combustion pressure and crank angle at which maximum pressure occurs. Crankshaft bending loads can be divided into: stresses in the plane of the throws, and stresses in the plane transverse to the throws. These are illustrated in Fig. 24. The improvement gained by lowering the rate of pressure rise in a lower squish combustion chamber [head C] is offset by the increase in crankshaft bending loads. Tangential Force on Crankpin, lbs RPM head A B C D 4000 341 1142 2077 2053 5000 681 1223 2405 1964 6000 691 956 2225 1780 7000 167 950 2621 1254 Here is a graph of the data above:  So what did we learn from this? 1) one main reason for a squish band is not a big power increase but it's for keeping the piston edge cool at high RPM (which lessens chance of detonation). Jennings had written that there was no need for one on engines reving less than 9000 RPM and without a compression ratio over 6.5:1 [higher ratios increase engine heat]) 2) higher MSV values are not necessarily better. 15.2m/s at 6000 RPM equates to 20.3m/s at 8000 RPM (the typical peak power RPM for a 200cc) which is the max Blair recommends. 3) the MSV that makes the best power is unfortunately also the one that puts the most stress on the bearings. 4) having too high a combustion pressure rise rate (over 30psi/degree) produces rough running which is another reason for keeping the MSV under 24m/s. Both 24.4m/s and 33.5m/s are MSV's that produced more than 30psi/degree in this research. Is their quoted "rough running" an occassional detonation or the "slow and inefficient burning in the latter stages of combustion" that Blair mentioned? This site says the pressure rise over 35psi/degree can be strong enough to cause a self ignition of the fuel. Here we can see what MSV's from 24.4 to 15.2 m/s at 6000 RPM are up to 9000 RPM (because MSV increases with RPM): RPM 6000 7000 8000 9000 MSV 24.4 28.5 32.5 36.4 m/sec 22.0 25.7 29.4 33.0 20.0 23.4 26.7 30.0 18.0 21.0 24.0 27.0 16.5 19.2 22.0 24.7 15.2 17.7 20.3 22.9 Click here for info on Excel spreadsheet caculators for squish velocity. |