Standard Reed Valve

The V-Force reed valve is better for high revving motocross bikes, but it still needs moderately stiff reeds to quickly close the gaps of their opening. Its maximum opening of the main reeds is 76% of a conventional reed valve, which is good but could be better (ie: less %). This valve gives noticeably better power at high revs.

V-Force Reed Valve

From the V-Force web site: "The VForce3 valve incorporates features you won't find with other system on the market. With such features as twice the reed tip surface, radius cage surface and more. By doubling the reed tip surface the petals now only need to open half as far to have the same flow as a stock style cage. This is a significant advantage when you factor in that a reed petal opens and closes 133 times per second at 8,000 rpm. The petals are only traveling half the distance of a stock style cage, so now fatigue to the petal has been greatly reduced, increasing petal life. This design also enables the valve to drastically improve the entire powerband with a significant boost in the bottom and mid. Instant throttle response is an understatement!"

Their stating that their reeds only travel half the distance isn't true. They've come closer to that ideal but not as close as my design.

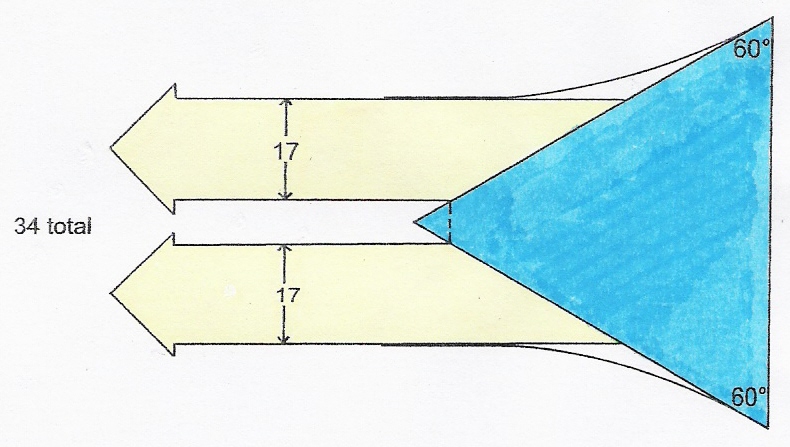

My new design of reed valve is also a 4 plane design like the V-Force, but its location of the planes (where the reeds rest) is much different. Instead of having two main reeds that open the most (as in the two previous designs), it distributes the total opening more evenly amongst the 4 reeds. The two main ones open a total of 53% of the maximum opening of a standard reed valve, and the two auxiliary ones open a total of 41% of a standard reed valve (for a total of 94%). This allows the use of reeds more flexible than the V-Force reeds. More flexible reeds, in addition to having excellent flow at high rpm's, allow better flow at mid and low rpm's. This reed valve effectively increases the powerband of a motocross bike, which is what is needed to compete with the new 4 stroke bikes. My design also incorporates means to lessen turbulence of gas/air as it flows through the reed valve in order to increase flow volume.

(The theoretical maximum distance of reed opening of these designs is based upon mathematical principles dependent on the closed-reed angle and length of reed.

But less distance than the theoretical maximum is available when the reeds tension exceeds the force of vacuum needed to fully open

them (which is needed with standard reed valves for use with high revving

engines).)