|

About

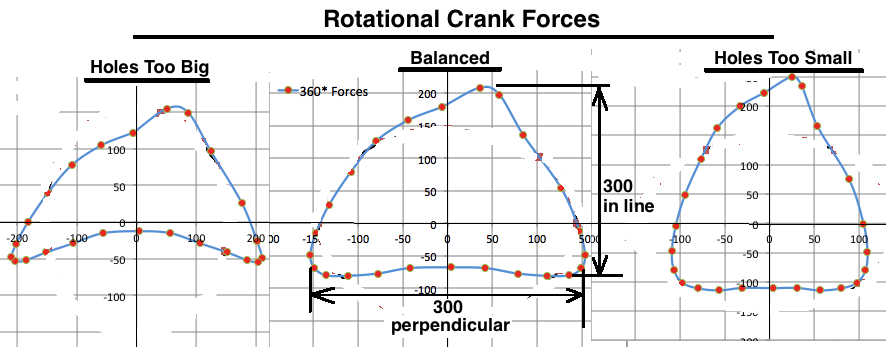

Balancing Engines for Less Vibration An imbalance in the crankshaft in relation to the reciprocating weight of the upper end causes vibration and a loss of power. Making sure your engine is balanced correctly is essential, especially if you are modifying the engine to work in a different RPM range than what it was designed for. When the piston goes to TDC and then is pulled back down by the crank, the force on the crankshaft is towards the cylinder head because that changing of direction creates a force of inertia upwards. Put any weight on a string and throw it away from you and then jerk it back to you and feel the outward force. Same thing. And the same thing happens at BDC. Those up and down forces create vibration. But that is countered by having holes in the crank wheels close to the conrod pin. The only problem is that the holes then allow a forward and reverse force to act on the crankshaft due to the unbalanced crank wheels. So a "balanced" engine has crank wheel holes just the right size to create equal forces in line with the cylinder and perpendicular to the cylinder. But since those forces peak every 90 degrees of crank rotation then basically the end result is a kind of triangle of forces. The graphs below are from my crank balance calculator. You can see that when the holes are too big that the predominant direction of force deviation if perpendicular to the cylinder. And when the holes are too small that the predominant force direction is in line with the cylinder.  Click here to read why I don't recommend using the balance factor method.

Click here to read of my tests which helped me develop my crank balance program. centrifugal force calculator (don't

enter linear speed. change m to mm, change kg to grams, change N

to lbf) Here

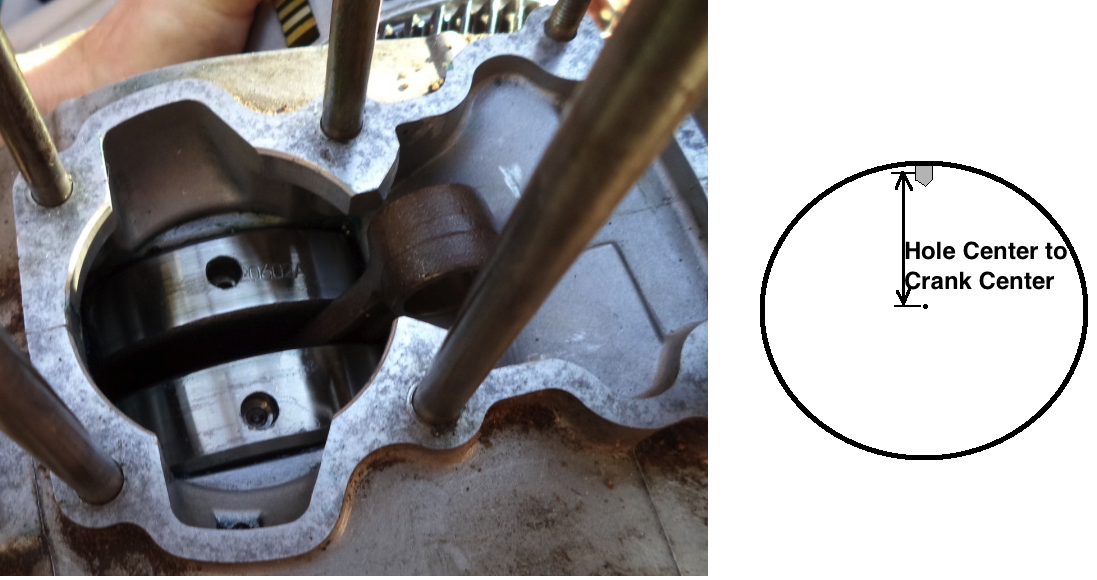

is a picture of my crank assembly with an additional balancing hole

just above the conrod pin. The 6 blue holes are lightening holes (although I wouldn't recommend any more than 4 if

the bike is for street use). The blue is foam filling half the hole.

The ends of each hole were later filled with JBWeld. I used foam just

to reduce the amount of expensive JBWeld used. The conrod hole and two

factory balance holes are already filled with JBWeld for increased

crankcase compression (although the change is very small).  You can drill extra balance holes

with any good electric drill although it's a bit tough. Much easier to

take it to a machine shop and let them put it on a drill press. Also

the holes can be drilled at the TDC or BDC location of the crank wheels

without even taking it out of the crank cases. Just put duct tape on

the crank wheels (after cleaning them with alcohol) to keep metal

shavings from going into the crankcase, and then keep the crank in

correct position by using vise grips on the primary gear above and

below where it meshes with the clutch gear. You can measure from

halfway through the angled drill bit tip and mark the drill bit at the correct

distance with black electrical tape wrapped around it. That way you have a visual

reference while drilling. Here's one of my cranks with holes drilled 180 degrees from the crank pin:  DIY Crank Balance Test:  Click here to read more about my spreadsheet which can be used to calculate the size of counter balance holes needed in any single cylinder crank. |