|

The Grubee engines are made for low

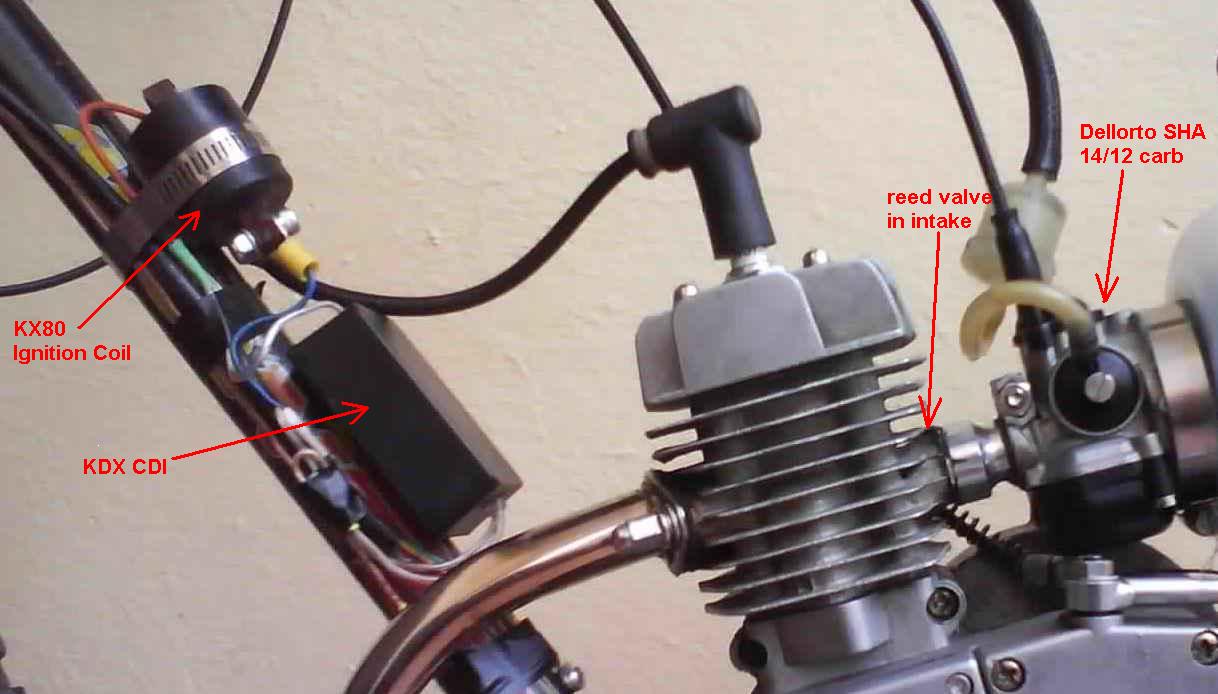

rpm performance (5000 max). The three reasons for this are: With these changes you can almost double the power output of the engine without making it unreliable. The first 3 changes together shouldn't cost more than $100 (if you use a cheap extension tube instead of a reed valve). I did all 4 of these to mine and now I can climb inclined streets that I had to walk the bike up before. It is really amazing and I get many astonished looks. Please ignore the stupidity of anyone who advises buying an expansion chamber. Expansion chambers aren't made long enough to be of any use to someone who wants low-rpm power. The common short pipes only enhance top end power (>5000rpm) and interfere with low-end power. A pipe designed for use with this engine that has a broad powerband and gives peak power at 4000 rpm needs to be 207cm (83") long. Pipes that peak at lower rpm's are even longer. [drawing] [software] No one makes these sizes. If you had one then you'd need a shift kit to keep the revs up at all speeds (extra hassle) and you'd destroy the bearings twice a year.  I made my own CDI unit by copying the design

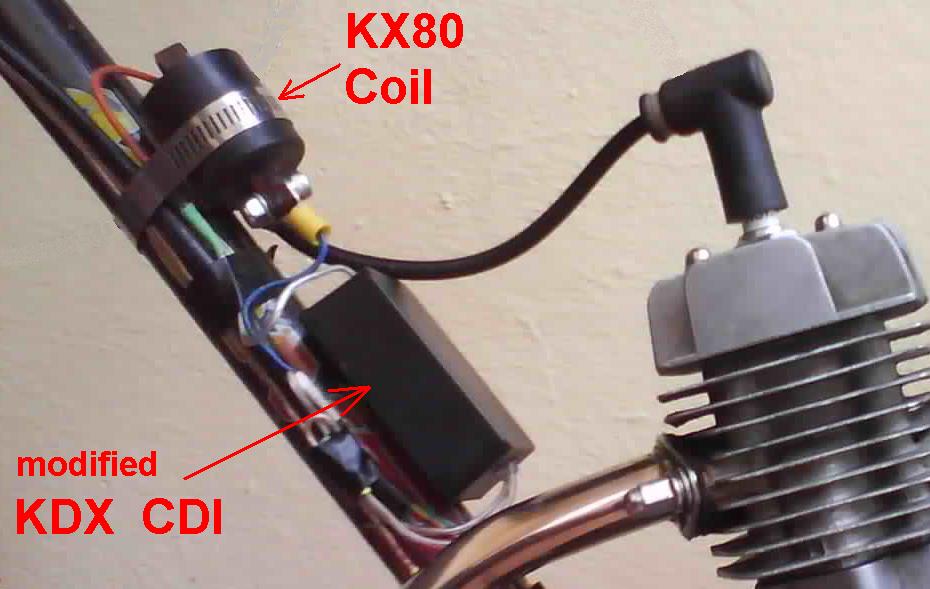

of the KDX200 CDI and adapting it for use with this Chinese engine. That,

in combination with a used high voltage coil, I improved the spark

strength and now have an ignition system that advances and then retards

the timing as revs are increased. It has strengthened the idling, made the

engine run cleaner and stronger, and allows more top rpms and less engine

vibration. The standard CDI has a spark timing of 28.5° to 41.4°

BTDC through the rev range. These are

the timings with my new ignition system: Here's a graph showing the ignition timing curves of these

CDIs: stock Grubee, mine, KDX200, RM250:  I can sell you a brand new modified CDI for $40. You will need to obtain an ignition coil and, like me, you can use EBay to buy a new or used high voltage ignition coil. (Only buy from those who claim it was working fine and that offer a guarantee if it is used.) How to Determine Timing: Take the spark plug out, stick in a screwdriver, rotate the magnet till you find the pistons highest position, mark with a felt tip marker one of the corners of the magnet and the stator plate where the magnet corner is. That will be your TDC reference point (but it will change with any other position change of the rotor). The ignition point (seen with an automotive timing light while running) on the magnet adjacent to the stator mark will be a few millimeters clockwise of the standard ignition mark on the magnet which indicates the advancement of ignition before TDC. Advancing the ignition (by positioning the magnet more CW) will make the magnet mark to be even more clockwise than the timing mark on it. After re-tightening the nut then find piston top again and remark the case for the new position. Use this formula to figure out how many degrees difference there is between the new position and the reference mark. Degrees=(distance between marks x 360)/(3.14 x magnet diameter) So if the magnet is 36mm and the marks distance is 3mm then the degree change is 9.5 degrees. MODIFIED KDX CDI

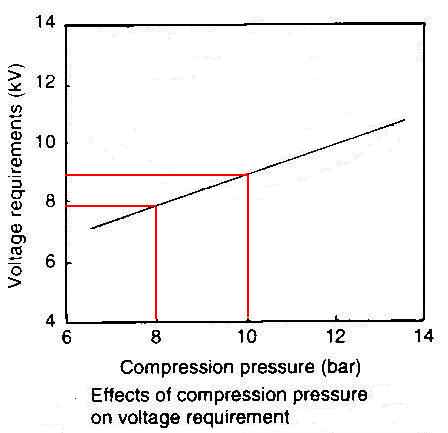

Years ago I owned the international version of the Kawasaki KDX 200 which was a great dirt bike and had a broad enough powerband to also be good on the street. When the CDI went bad I was told of a man that repaired them. He showed me how to dig into them in order to replace the SCR and charge capacitor which are the two parts normally going bad. Being an electronics technician I then figured out the schematic for it and the values of all parts used in it. Then I tinkered around with different values of parts in order to get more mid range power and get more top rpm's. I settled on adding 10% more capacitance to the part of the circuit which determines the timing curve. I used that CDI both on the street and on the motocross track. It worked great! I also experimented with different values for the main charge capacitor, the one that holds the peak voltage from the magneto coil. Standard was 1.5uf and at 2uf the ignition system (and engine) would lose power at high rpm's. That makes sense because there is a delay time for charging the capacitor and the higher the rpm's the less time is available to charge the capacitor. On the Grubee 48cc engine 2uf will not allow the engine to run at all. That is because the magneto coil, which develops voltage as the rotor magnet rotates, has more winding resistance and less voltage than the KDX motorcycle. So then I tried 1uf and tested it on the street with amazing results. One uphill street I tested on allowed 14.5mph with the 1.5uf capacitor. With a 1uf capacitor it went 17.5mph! That means the lesser capacitance was charging to a higher voltage which translates to more voltage and current at the spark plug. (More capacitance charges slower and to a lesser voltage level if not given enough time to fully charge. Less capacitance charges quicker and to a higher voltage in the same amount of time.) A CDI ignition system is all about voltage. The positive voltage from the magneto coil charges the capacitor which is manipulated into a negative spike of voltage of the same amplitude to the ignition coil which multiplies it into thousands of volts sent to the spark plug. Comparison to the standard CDI: On one long uphill I test my bike on I went 20.5mph up it. 15 minutes later with the modified CDI the mph increased by 10% to 22.5! At high rpm's the standard CDI allowed much engine vibration but the new CDI cut that in half for a much more pleasant ride. Since 2.5% more power is derived from each 33% increase in spark power then a 10% increase of power means the new CDI has 133% more spark power! [read more] This data is from the research paper "Devices to improve the performance of a conventional two-stroke spark ignition engine" which includes these statements: "With the high energy ignition system, combustion stability is improved due to high spark discharge, which initiates the combustion process more effectively at higher compression ratios and with leaner fuel-air mixtures compared to the normal ignition system. At a high compression ratio of 9:1, with lean fuel-air mixture (A/F=15.2), the maximum improvement in brake thermal efficiency obtained with this high-energy ignition system is 16.5% (at 2.76 kW, 3000 rpm)" (Thermal efficiency is the ratio between the mechanical power output and the heat content of the fuel consumed. These engines shouldn't have a compression ratio that gives more than 150psi because of the weak bearings.) So this is a

motorcycle CDI which has four selectable timing curves (read more) and a smaller charge

capacitor to accommodate the weaker magneto coil voltage. It has four

wires, two which connect to the blue and black wires from the magneto, and

two which connect to the motorcycle ignition coil. Any dirt bike coil

should work but I have been using ones that have an input wire (instead of

blade connector), spark plug wire & cap, and are from an MX

bike smaller than 100cc. Three of the wires need to be soldered to

their mating wire and then the heat shrink tubing shrunk over the exposed

metal for good insulation. For connection to my bicycle frame I just use

double sided foam tape. I ride on bumpy roads and it stays in place. The

ignition coil is held in place with double sided foam tape and a hose

clamp. To connect the ground wire to an ignition coil with frame ground

you'll need a 1/4" diameter bolt, nut, and washer. Here's 3 drawings

showing how to connect to the 3 types of ignition

coils:    Questions

& Answers Why is yours more expensive than some other CDI's?

Because mine isn't made cheaply by slave labor in China. I value my

employees and pay them well. My CDI, unlike all others, is especially

designed for the Grubee engine. All others are either made for 4

strokes (that don't retard the timing at high rpm's) or they retard the

timing over 7000 rpm (for heavily modified engines that rev up to at

least 9000 rpm).  Can I just

use a KDX200 CDI? Yes, if you can figure out the wiring. But the

voltage output to the ignition coil won't be near as strong as mine since

it isn't adapted for use with the Grubee engine. What if I

don't have a soldering iron or know how to solder? Learn from

these online soldering tutorials for

beginners: Contact Michael:  |