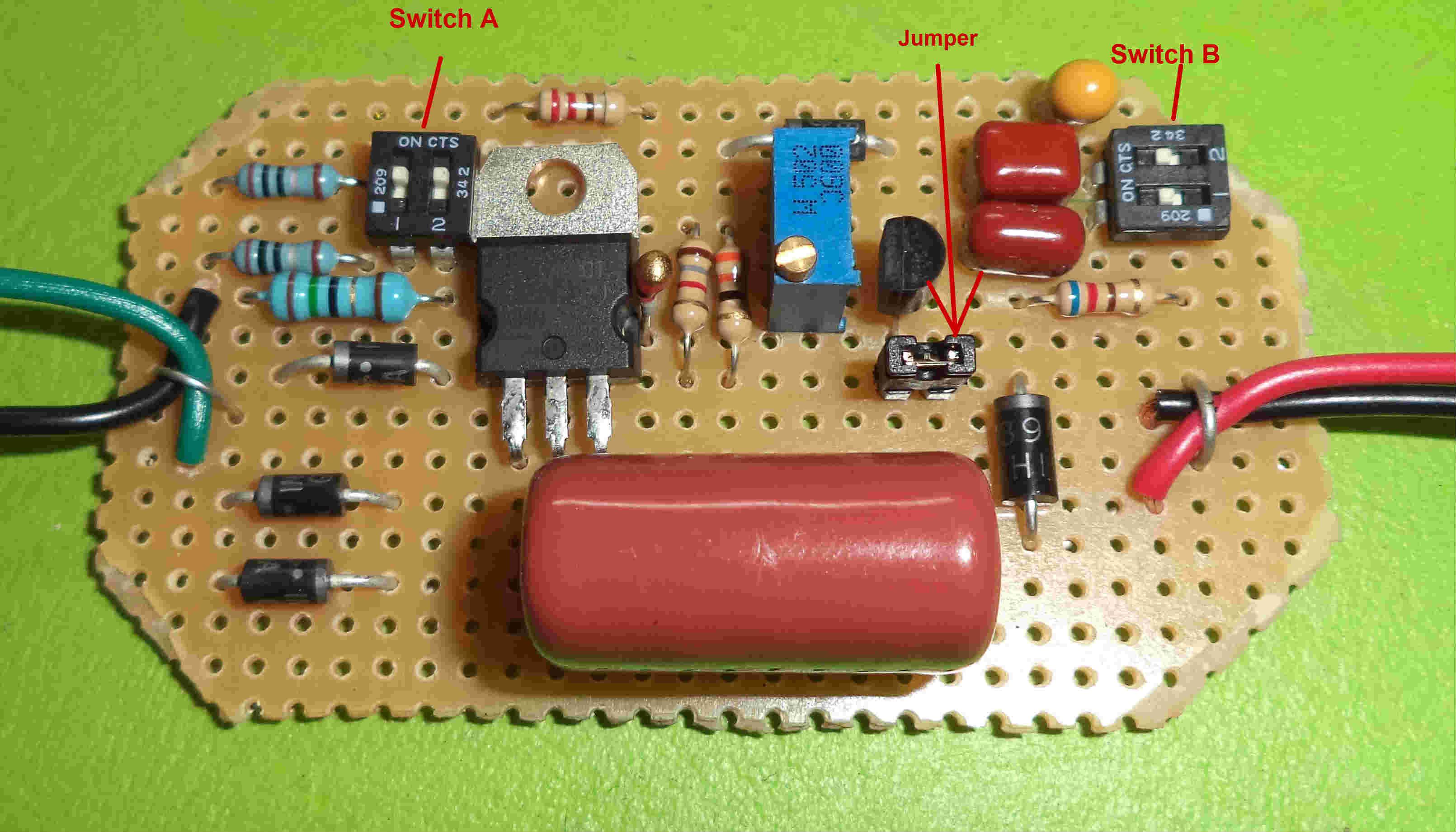

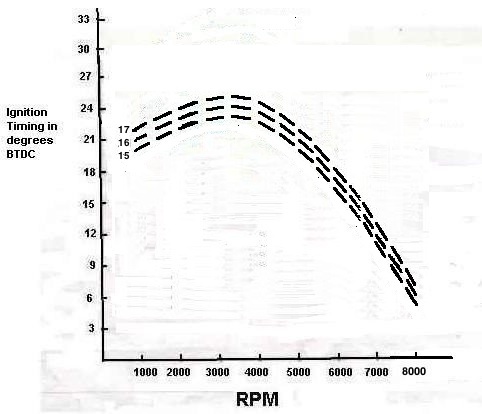

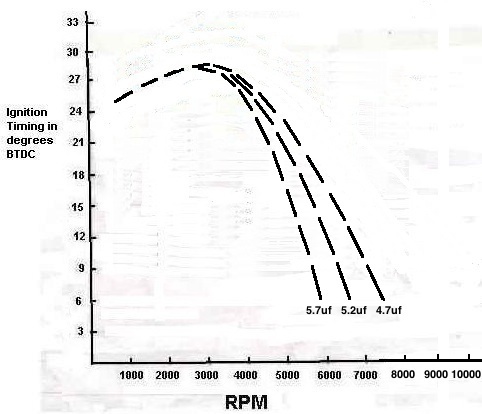

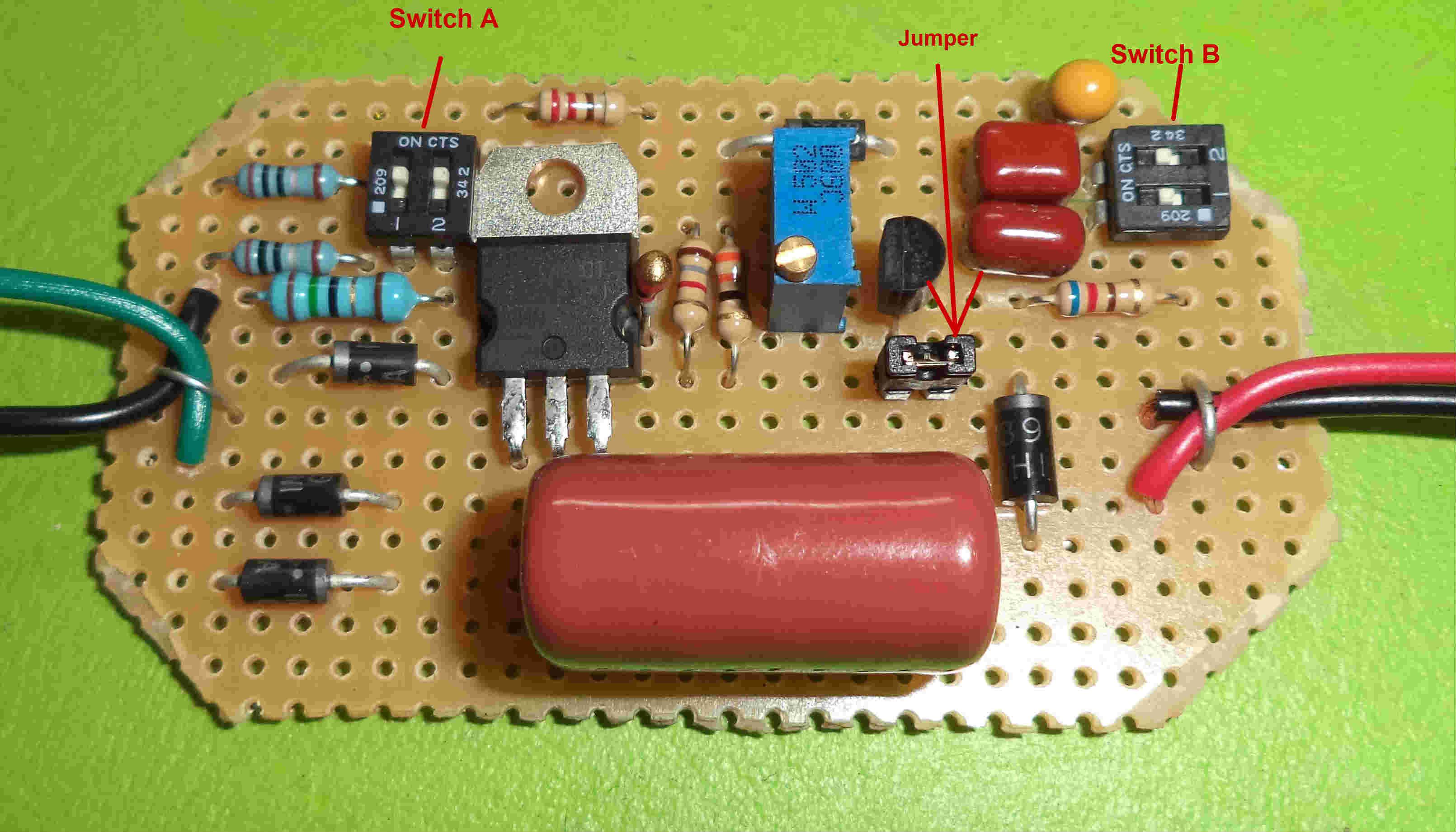

High RPM Jaguar CDI For decades there have been two types of Capacitive Discharge Ignitions (CDI's) for two stroke engines; analog and digital. Their purpose is to cause the ignition spark to happen at a certain amount of crankshaft degrees before the zero degrees of the pistons top most position in the cylinder. Above 7200 (more or less) rotations per minute (RPM) of the crankshaft the best engine performance has been with digital CDI's because an analog CDI retards the ignition too much. This page reveals a new type of analog CDI which has an ignition timing curve (see graph below) in between that of a digital CDI and an analog CDI which gives enough ignition advance at high RPM for better performance and lets the engine achieve higher rotational speeds. It uses only the voltage waveform from the stator coil as a timing reference, as opposed to those that use a voltage input separate from the stator coil.   DESCRIPTION This modified analog CDI has two main features; 1) It allows the owner the selection of different input resistance which affects the whole timing curve, and selection of different capacitance which affects the timing curve above 3500 RPM. 2) It causes the ignition to happen earlier at high engine RPM (more than 7200 RPM) than a standard analog CDI. It does this by activating a relay above 6000 RPM which changes the RC value in the retardation circuit to retard the timing less than it normally would. Higher input resistance causes more advancement of the whole ignition curve, and higher capacitance causes more retardation of the ignition curve above 3500 (with the greatest change at higher RPM). This allows the owner the ability to adjust the ignition curve to be more correct for different engines and expansion chambers. Selection of different resistance and capacitance is done by moving the levers of the switches that are soldered to the circuit board. Input resistances available are 15 ohms, 16 ohms, and 17 ohms by different lever positions at switch labeled Switch A. Circuit capacitances available are 4.7 microfarad, 4.9 microfarad, 5.2 microfarad, and 5.7 microfarad by different lever positions at switch labeled Switch B.   Why is 7000 RPM the engine speed above which the ignition timing needs to retard less? From 3500 to 7000 the fuel/air mixture gets mixed better as RPM increases due to turbulence. The more atomized the fuel droplets are due to turbulent mixing the quicker the whole mixture can burn. A slow burning mixture needs to be ignited earler (more advanced timing) so that the peak cylinder pressure can happen around 15 degrees after top dead center. A quick burning mixture needs to be ignited later. Above 7000 RPM fuel atomization improves very little with more RPM so the ignition curve needs to almost flatten out above 7000 RPM. If you take off the box lid (using a small phillips screwdriver) you will see micro switches (labelled "A" and "B" in the photo below) on the components board and the jumper (black rectangle that can be pulled up and off of the posts). The A switches allow correct input resistance selection. You have 4 timing curve selections with the B switches (ie: both off, B1 on + B2 off, B2 on + B1 off, both on) that mostly affect mid range and upper RPM power. Pulling the jumper off disconnects the hi RPM circuit that limits timing retard above 8000 RPM. Click here for full information.

|