|

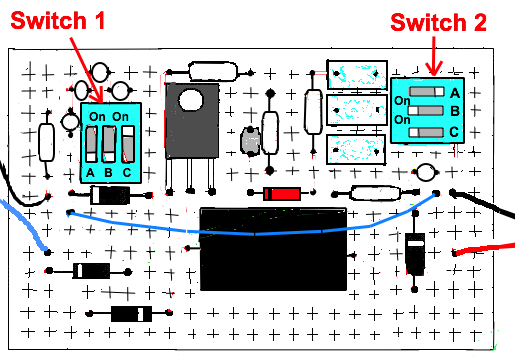

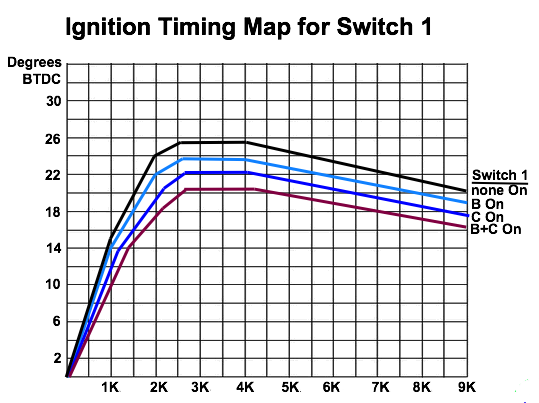

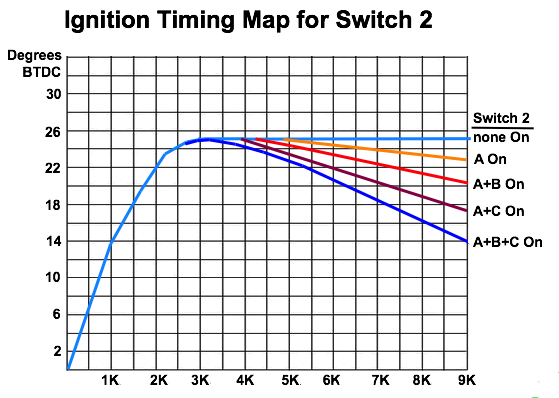

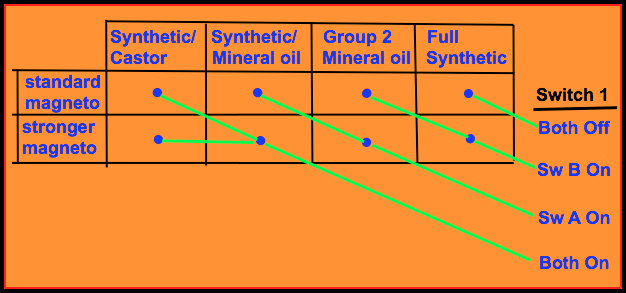

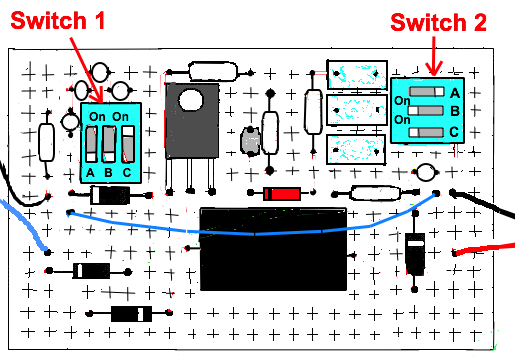

There are two on-board multi-switches on the circuit board.  Switch 1 is a triple switch that controls the whole ignition timing curve (to be more advanced or retarded/delayed) but affects the middle of the curve more than the end of it. Switch 2 is a triple switch that controls the high RPM timing.  Switch 2 (SW2) is a triple switch that controls the amount of retard to the timing after 4000 RPM. So it has the most affect at high RPM. When high RPM timing is not retarded enough then that limits how high the engine can rev.  DETERMINING BEST SETTINGS: You can test the settings for your bike to see what works best. Jetting, porting, compression*, and exhaust pipe all affect the needed timing. Whichever settings allows the best power are the ones you should use. * high compression heads with squish bands (when the clearance to the piston is no more than .8mm) burn the mixture quicker and so needs retarded ignition via Switch 2Engine Oil and Ignition Timing My own testing proved that different types of engine oil affect the speed of combustion which affected the needed ignition timing for high RPM. That combined with the strength of the voltage going to the CDI affects what setting you should consider "baseline" for switch 1. "Stronger magneto" below refers to using either a stronger magnet, or a stronger stator coil that is fatter and without the 3rd wire for lighting. A 3rd wire means the main coil has less turns of winding to make space for the lighting coil, so a coil with 3 wires outputs less voltage than one with 2 wires. Click here to see what many engine oils are made of (what types oil are in them). You can't rely on promotional info.  Fine Tuning First please buy a WalMart speedometer or a tachometer if you don't have one! I do 2 tests, an uphill test and a top speed (rop RPM) test. Here there is an uphill that my bike can't climb. I judge the low RPM power via timing (of switch 1) by how far the bike goes up the hill before dying. On a flat road I see what the max speed/RPM is for each setting for switch 2. Expansion Chamber & Porting: The pipes header length determines the speed at which the expansion chamber stops further progress. It has to be "tuned" for your ride. The shorter it is, the more the top speed is possible if the porting is adequate. (but keep in mind that the stock low height of the exhaust port also limits top speed and it has to be raised 2-4mm for a significant improvement in speed. Raise the transfer ports 1mm for every 3mm change in exhaust port height. I use a cheap rotary tool with cutting discs since the aluminum ports are easy to grind down.) HOW TO UTILIZE THE SWITCHES: Just remove the boxes 4 screws (hidden under rubber feet) with a small Phillips screwdriver. Once the box lid is removed you can see the switches and easily change their lever positions using your fingernail or a small screwdriver. The on positions of Switch 1 are "up" and the switch 2 on positions are "left" when the components board is positioned the same as in the drawing below. More input resistance (by switch 1 levers down) causes more ignition advance. More capacitance (by switch 2 levers on) causes more top RPM ignition retard. Try to remember it this way when you're out testing: The more switch 1 is off, the more mid range timing is advanced which affects mid range power. And the more switch 2 is on, the more retarded the timing is (for high RPM) which affects power at high revs. Usually engines that rev less than 8K don't need any ignition retard by switch 2, so those persons can keep switch 2 levers to the right.  |