|

NT/Speed Carb Jetting tips

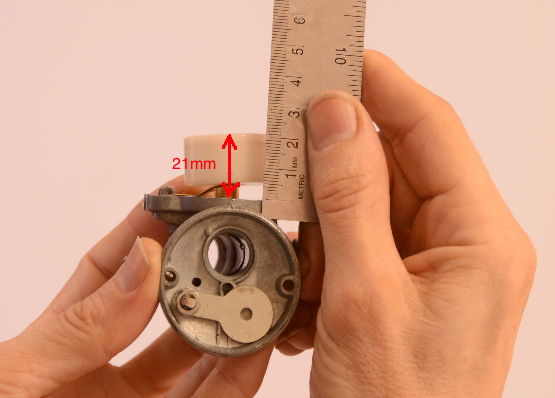

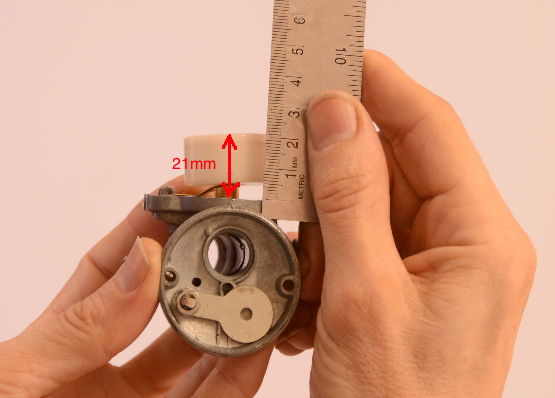

First make sure the carb float height is correct. (On the Grubee's NT it's 21mm measured with carb upside-down and gasket removed. Measure from gasket seating surface to highest point on float.)

Set the main jet first for correct running at wide open throttle and max speed. The perfect size will be one size richer than that which gives you the best top speed. Instead of buying various sizes you can remove the jet and drill a larger hole if you need a richer mixture. (Dellorto jets will fit this carb). Or if you need a leaner mixture then just heat the jet with candle flame, melt solder into the hole, and drill a new hole. You can use a micro drill bit from amazon.com

Needle adjustments for the NT:

Next set the needle height for correct idling and accelerating. Sometimes the needs of the two conflict. I would set its height for correct acceleration from 1/4 to 3/4 throttle and then if its tip is less than 1.6mm wide I would put solder onto the needle tip to lean the idle mixture. If you can't get the needle low enough (leaner) you can file more grooves on the needle higher than the current highest one and reposition the clip there. If you put solder onto it then just the lowest 11mm (1/2") of the needle should be soldered. A bottom width of 1.65mm was necessary with my NT carb when I lived at high altitude. Radio Shack sells good solder but don't buy the lead-free type since it is much harder to melt.

Adjustments for any other carb that has a separate idle mixture adjustment:

IDLE: Adjust the slide stop screw so the idle is slightly high (and keep adjusting as is needed as you change the idle air screw setting). Set the idle air screw for max RPM at idle. If that winds up being less than 1 turn CCW then the idle jet is too large. If it ends up being more than 2 turns CCW then the idle jet is too small. Replace the idle jet or adjust the jet hole size accordingly. On a hot day (80 degrees F or more) you should be able to start the engine without choking the carb if the idle circuit is rich enough.

NEEDLE HEIGHT: Set the needle height for good running from idle till almost 3/8 throttle. If it loses all power opening the throttle fast then the needle is too low (too lean). If you very slowly open the throttle and the engine runs irregularly then the needle is too high in the slide.

SLIDE CUTAWAY: This should be adjusted last. If the engine runs rough till 5/8 throttle then the slide cutaway needs to be higher to lean the mixture at those throttle openings. Doing this may necessitate enrichening the idle mixture a bit by either turning the idle air screw in or installing a richer idle jet. The left drawing shows the additional cut needed on the Mikuni 18mm carb. If you ever need to lower the cutaway and don't want to buy a new slide then just cut grooves into it and put JBWeld there, keeping the face smooth and even with the slide by placing electrical tape onto its outer surface so it can dry correctly formed. Afterwards you can file it down till it has the extra extension length you wanted.

As far as main jet hole diameters, all I can give you as a guideline is what worked for me at sea level with these different engines. (Reed valves and extra steep transfer ramps cause a need for extra rich jetting):

60cc with no cylinder mods other than smoothing out the top of the transfer roofs, piston port intake, no transfer ramps, Pirate Cycles billet intake manifold, standard exhaust pipe, standard 100 psi, 14mm Dellorto SHA carb, .58mm (#58) main jet

60cc, piston port intake, 7.5" long intake, 3mm off head for 120 psi, standard exhaust pipe, Jaguar CDI with no jumpers installed, ported for 161/121 degrees exhaust/transfer durations with 1.2mm transfer ramps at 60 degrees from horizontal, 14mm Dellorto SHA carb, .69mm (#69) main jet

55cc, Rock Solid reed valve, torque pipe, 130psi compression, Jaguar CDI, ported 169/122 porting w/o transfer ramps, 14mm Dellorto SHA carb, .72mm main jet

Jetting a Normal Carburetor:

follow this sequence:

PILOT JET:

Set the idle air screw for max RPM at idle (no throttle). If that winds up being less than 1 turn CCW then the idle jet is too large. If it ends up being more than 2 turns CCW then the idle jet is too small. Replace or adjust the jet hole accordingly. On a hot day (80 degrees F or more) you should be able to start the engine without choking the carb if the idle circuit is rich enough. Too lean an idle jet and the idle takes a while to settle back down to the resting RPM after blipping the throttle. Also the time it takes for the engine to rev up is delayed. If you turn the idle air screw counter-clockwise from 1.5 turns out then the idle speed will go up. Too rich and the engine sounds congested. If you turn the idle air screw clockwise from 1.5 turns out then the idle speed will go down.

MAIN JET

Too lean and at wide open throttle (WOT) the engine will get too hot and possibly seize the piston when it starts to melt. You can take the piston out and look under its crown to see if the oil deposit there is black which indicates too much heat. Spark plug color is lighter than the desired chocolate brown color. Too rich and the engine may run rough and not reach its normal top speed. Spark plug color will be too dark.

NEEDLE HEIGHT

Set the needle height for good running from idle till almost 3/8 throttle. If it loses all power opening the throttle fast then the needle is too low (too lean). If you very slowly open the throttle and the engine runs irregularly then the needle is too high in the slide.

NEEDLE TAPER

If the taper angle is right then you'll have good running from 1/4 open to 3/4 open. If it loses all power unless you very slowly open the throttle then the needle taper is too small. If the engine runs irregularly at 1/2 throttle then the needle taper is too big. When you change to a larger taper needle then you'll need a smaller main jet. And when you change to a smaller taper needle then you'll need a larger main jet.

SLIDE CUTAWAY

This should be adjusted last. If acceleration off of idle (from zero to 1/2 throttle) is rough then the slide cutaway needs to be higher to lean the mixture at those throttle openings. If the acceleration is weak then the cutaway may need to be lowered which you can do with JBWeld. Add onto the slide by 1mm at a time.

Main Jet Replacing/Drilling

I'm too conservative to buy a bunch of jets just to never use most of them. If you are insistent on buying jets then get the Dellorto jets from Treatland and all other jets from SUDCO. Jets-R-Us sell cheap imitation jets that aren't sized right.

So I just drill out my jets and sometimes I also change the needle shroud height if the carb has one. Higher shrouds cause more vacuum on the needle and main jets which is like you increased the jet size. I use a micro drill bit set that comes in steps of .03mm to drill out the main jet. If a smaller size is needed then I heat up the jet in a flame and then melt solder into it (not too much) and then drill it out. If the drill bit is too small for the drill to grab onto then I make it grab onto the jet threads and hold the drill bit with pliars and then push the bit into the hole area as the drill spins the jet.

|