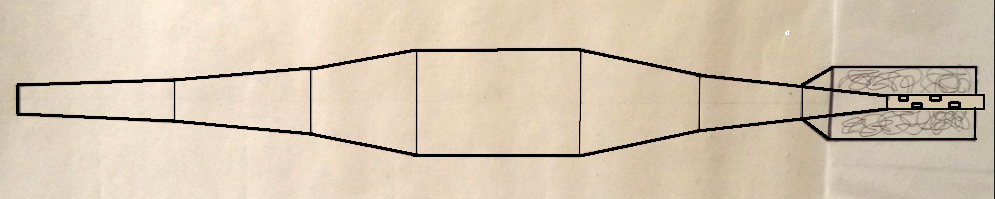

| Since I'm always wanting to find a cheap solution for economically challenged motorized bicycle riders I came up with this idea: to use the last half of the standard muffler connected to a true diffuser (expanding cone). It turned out to be too short to benefit the below 8000 RPM that this engine is ported for. The shorter a pipe is, the quicker its return waves come back to the cylinder and so it benefits a higher reving engine  So then I made it into an up pipe with almost twice as long header to get its effect to happen at less than 8000 RPM. I think it helped a little but not much, probably due to the belly being limited to 50mm to match the muffler diameter. I calculate the ideal for this 48cc engine is 55-70mm diameter. So this low alternative is something people could try as long as they don't have high expectations.  You might think that not having a constricting cone (baffle cone) was a big part of the problem. I have a Suzuki AX100 with only 4 gears and after making a number of pipes for it I returned to the original idea that the original pipe had which was a very long belly ending in a flat plate with a hole in it which was the beginning of the muffler. A flat plate can return the internal sonic wave just as well as a cone although it does limit its length (in time). The extra long belly caused the return baffle wave to only interact with the porting at too low a RPM to matter much and so there was a very linear power response to the setup due to only the return diffuser wave interacting with the engine at the typical RPM of use, giving the feeling that it was more like a 4 stroke. Of course my test pipe on my motorized bike didn't have a super long belly to mimic the AX design, only a gutted stock muffler. There's just not enough room on a bicycle without having a freakish looking pipe as the result.  Here's a recent pipe with an easy to make silencer (see drawing below) which was OK but a bit louder than I like. It has a dual coned diffuser and a 240mm baffle in contrast to the short 180mm baffles of MX pipes (which give more peak power but a shorter pipe powerband). I like how it looks though with the baffle/silencer section running along that frame tube at 57 degrees.   It has the ideal 70mm belly width that is just enough to not burn your leg if you strap it to the frame. Here's a vertical shot showing its width:  I was just being lazy when I made the diffuser a dual section since 3 sections is best for engines with reed valves. Also the internal sonic wave is most efficient when not having to go thru turns which rearrange it a bit. So my next pipe is going to be a straight up-pipe to maximize its effects of engine boost, with a 3 cone diffuser and 200mm two section baffle (for changing the form of the baffle return wave which benefits power).  Here's a graphic showing that the silencer is of a simpler design. Instead of having a small tube with holes running thru the silencer it just has metallic scouring pads. So I will see how it runs and sounds. Simpler is always better, both for others to copy/make and for production. I predict it will be noisier but hopefully not by too much. The sound wave will lose energy (strength) as it causes the filaments of the scouring pads to flex. I know that by the basic physics law of conservation of energy which states that energy can be transformed but not eliminated.  This graphic shows how in a racing silencer the sound wave pressure escapes thru the little stinger holes but almost none of that escaped wave directly bounces back into the little hole. As the waves reverberate inside that part of the silencer their energy gets transformed into movement of the fiberglass till there is no sound left. The straight thru path of the stinger presents no resistance to the pulses of hot exhaust gases to not create any additional backpressure other than what the small size of the beginning portion of the stinger presents. It's a great design but presents one more step of complexity to anyone building a pipe.  In case you wonder how I know so much about expansion chambers, it is because I cheat. I made my own pipe calculator with return wave simulator so I can try many changes virtually and see the results on the pipe power graph. [read more] |