Combustion of

the fuel/air mixture does not happen all at once like an explosion does.

It happens as a progressive burning of the fuel, starting from around the

spark to the outermost combustion area. When the spark happens in relation

to crank degrees before top dead center (°BTDC)

of the piston is something that needs to vary according to engine rpm

so that maximum combustion pressure of the burning fuel/air mixture

happens between 15 and 20 degrees after top dead center (ATDC). That is

necessary for the most power to be transmitted to the

gears/sprockets/tire. As engine rpm's increase, the amount of time from

the piston being at a set amount of °BTDC to

being at top center decreases. But the amount of time that the fuel/air

mixture needs to burn remains the same (with the exception above 7000rpm

when the extra turbulence caused by the squish band shortens the

time needed to burn). Going only by this aspect of combustion it would be

ideal for the CDI to increase the °BTDC of the

timing as the rpms increase, in a linear fashion. This is more or less

true for a 4 stroke engine, but for a 2 stroke there are other factors to

consider: The following

is from Eric Gorr's paper "Basic 2 Stroke Tuning" where he talks about advancing or

retarding the whole ignition curve of an advancing/retarding CDI on a dirt

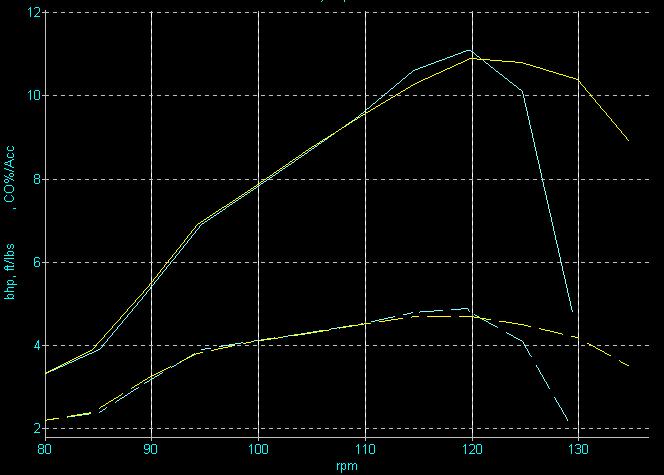

bike by changing the stator position CW or CCW: Here is how changes in the static ignition timing affects the power band of a Japanese dirt bike. Advancing the timing will make the power band hit harder in the mid range but fall flat on top end. Advancing the timing gives the flame front in the combustion chamber adequate time to travel across the chamber to form a great pressure rise. The rapid pressure rise contributes to a power band's "Hit". In some cases the pressure rise can be so great that it causes an audible pinging noise from the engine. As the engine rpm increases, the pressure in the cylinder becomes so great that pumping losses occur to the piston. That is why engines with too much spark advance or too high of a compression ratio, run flat at high rpm. Retarding the timing will make the power band smoother in the mid-range and give more top end over rev. When the spark fires closer to TDC, the pressure rise in the cylinder isn't as great. The emphasis is on gaining more degrees of retard at high rpm. This causes a shift of the heat from the cylinder to the pipe. This can prevent the piston from melting at high rpm, but the biggest benefit is how the heat affects the tuning in the pipe. When the temperature rises, the velocity of the waves in the pipe increases. At high rpm this can cause a closer synchronization between the returning compression wave and the piston speed. This effectively extends the rpm peak [power] of the pipe. Below is a dyno print of the horsepower difference in a 50cc engine that had the timing retarded 4 degrees which resulted in the powerband extended 1000 rpm more.  |