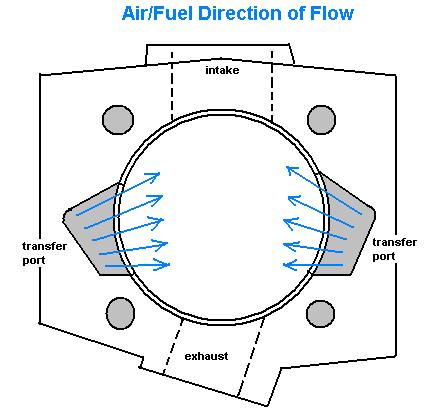

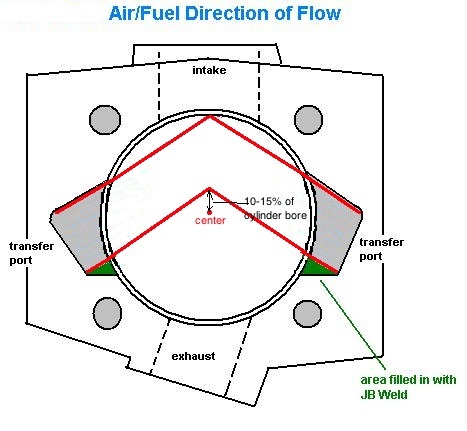

Here you can see the carbon deposits on top of the piston showing that some intake mixture is going out the exhaust port. This causes a loss of power. The deposits should be going only rearwards so that the mixture goes back and then upwards towards the spark plug.  This mod will significantly boost engine power by increasing the amount of air/fuel mixture burned each cycle. Here's a drawing showing how the stock Grubee cylinder has the wrong angle for one side of each transfer port (the bottom side in this drawing) which directs some of the intake gases too close to the exhaust:

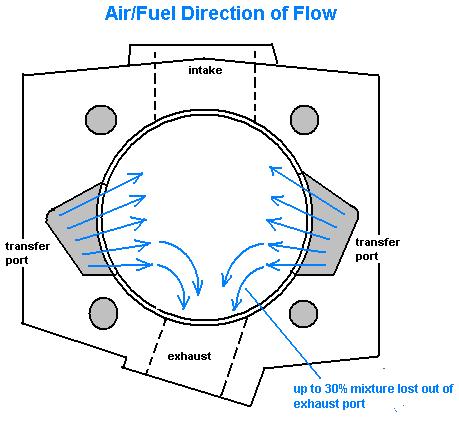

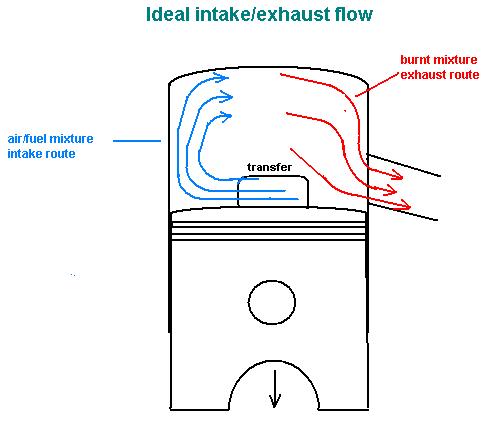

This shows how some of the intake charge can be drawn directly out

of the exhaust port which results in power loss and increased pollution

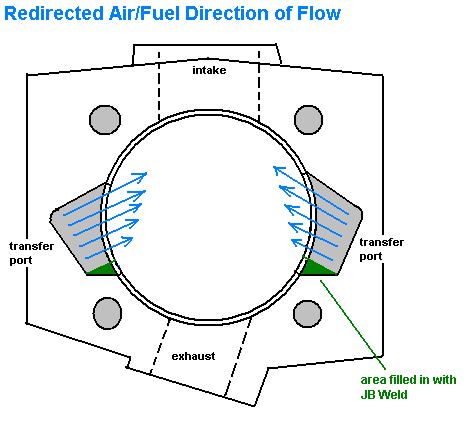

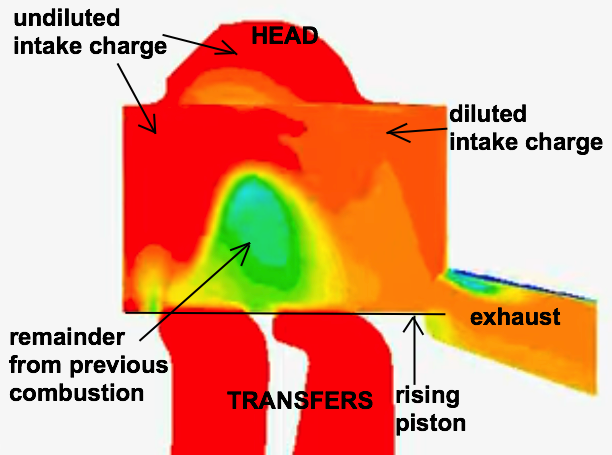

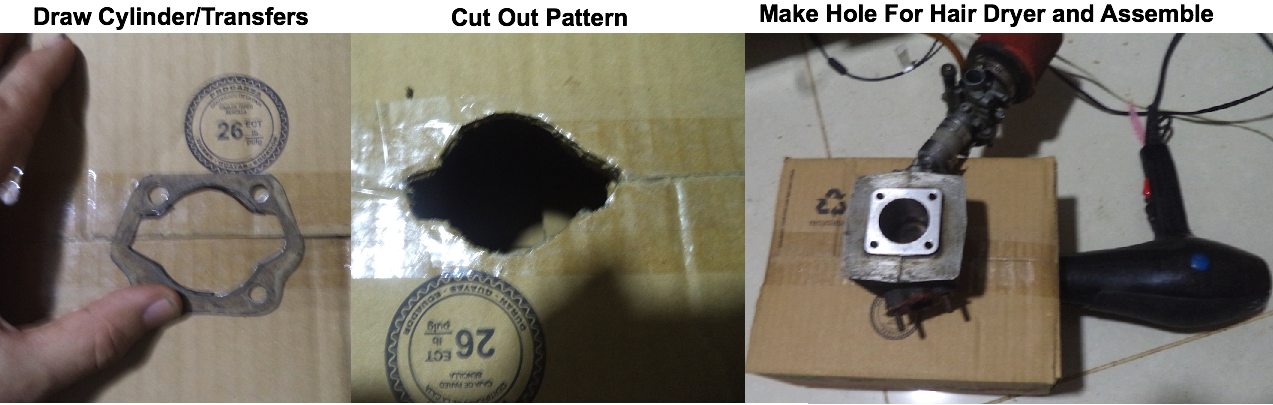

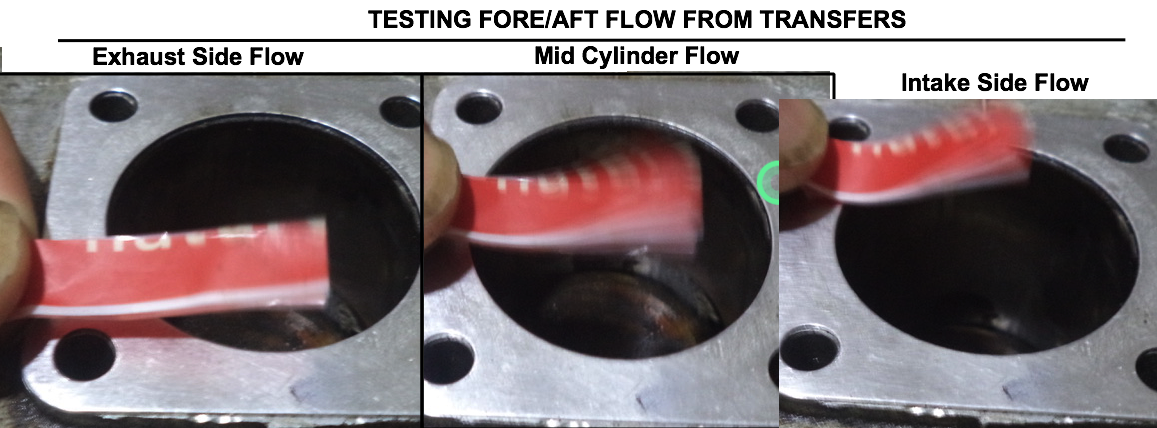

from unburnt fuel exhausted.  This shows how if the angle is corrected that the intake charge will all be directed toward the intake side and away from the exhaust port. This results in power gains and less contamination of the air:  This shows the correct angles of the transfer ports according to professor Blair:  HOW TO USE JB Weld: Mix equal portions of the two pastes. After cleaning the cylinder and transfer ports with carburetor cleaner use a screwdriver to reach into the transfer ports (from bottom of cylinder) and apply the paste to the exhaust side of one transfer port. Glob it on because you can use your dremel later to remove any excess. Then stretch a 4" length of electrical tape and place it vertically on the cylinder so that it keeps the JB Weld from drooling out. Then place the cylinder on its side so that the JB Weld will dry at the intended angle. Gravity will cause the paste to level out. Put the cylinder in the sun or warm room for it to dry quicker. After it dries then do the same for the other transfer port. Use your dremel or exacto knife (when not completely dry) to trim the paste to a width at the cylinder of close to 1/8" (3.5mm). Use the knife and then the piston with rings on it to scrape off the excess glue from the cylinder. Manually move the piston up and down in the cylinder to scrape the glued area.  Electrical tape over the transfer port edge, and the cylinder placed so that the glue will "level out" at the correct angle:  Here's a drawing and computer simulation of the high pressure intake mixture (blue in the drawing and red in the video) entering the intake side of the cylinder. Some intake charge will always be lost out the exhaust port but if the intake charge is correctly directed toward the intake side of the cylinder then there will be less dilution of the mixture with combusted gases. The combustion gases will more effectively be pushed out of the cylinder by the intake gases so that a greater percentage of intake gases remain for combustion.   How To Test Flow Direction You can use a carboard box and hair dryer to test the direction of the air flow, whether or not it is suficiently rearward. Put in the piston so that it opens 3/4 of the transfer ports.  Testing the flow with flexible plastic revealed good rearward flow thanks to my placing JBWeld at the front of the transfers. If you make a boost port you will see that it allows some of the flow to be forward which means it will disrupt the scavenging and lower power. The bore of these cylinders is just too small for a boost port.

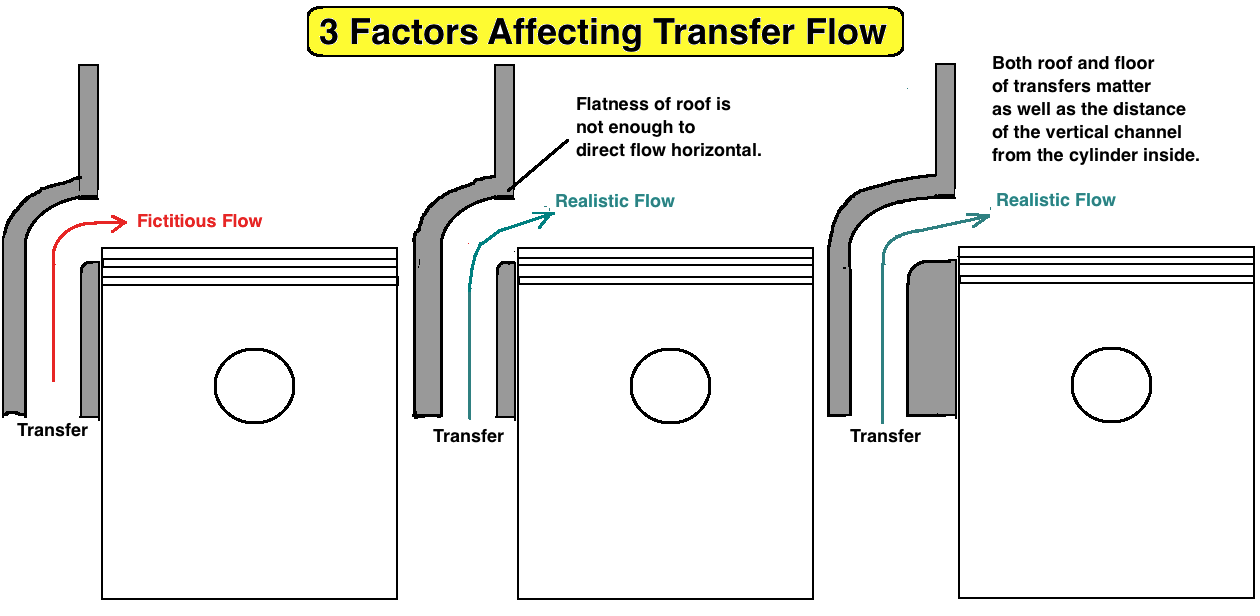

ANOTHER TRANSFER PROBLEM The stock chinese bicycle engines don't have the vertical transfer channel far enough away from the cylinder interior to allow the incoming charge to be mostly horizontal. This graphic explains. So the intake charge will enter too vertical no matter what angle you make the transfer roof to be. So be glad they designed the engine with a low crankcase compression ratio because if they made it with a normal 1.5:1 ratio then there would be too much transfer pressure and the mixture would enter too fast and loop around and some of it exit the exhaust port.

POSTSCRIPT Now I realize that the carbon pattern is only worth looking at if you put in a new piston and then do a fair amount of WOT testing, because at the mid range RPM we often ride at going around town the expansion chamber (if you have one) causes a loss of intake charge out the exhaust port, and this is unavoidable and not the fault of the transfer port design. |