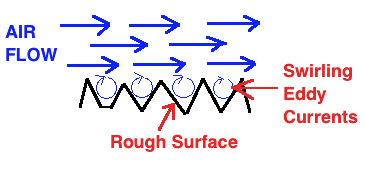

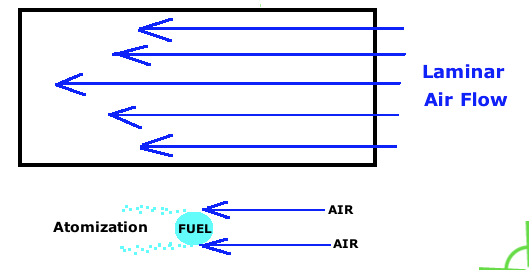

Wikipedia says "Flow bench testing shows that the difference between a mirror finished intake port and a rough textured port is typically less than 1%. The difference between a smooth to the touch port and an optically mirrored surface is not measurable by ordinary means." Why? A rough surface reduces surface friction which increases the outer zone speed, but since the overall volume ingested by the engine remains the same then the inner zone slows down which keeps the average air speed the same. So How Can It Help? Changing the air velocities for less variation from inner to outer also changes the fuel atomization. Smaller droplets aid quick combustion, and large droplets aid engine cooling, both being important.  Does A Rough Surface Increase Atomization By Increasing Turbulence? No. The turbulence at the surface is extremely minor. It has no effect on the majority of the mixture. How it affects atomization is by changing the profile of air speeds in the different zones. Does Reducing The Variation Of Atomization Increase Engine Power? It may for some engines. This needs to be tested correctly. Its possible that too much variation is bad for engine power. Click here for my video on this subject. Click here to download the spreadsheet mentioned in the video. Conclusion I think the bigger the passageway diameter, the greater the difference between inner and outer air velocities and so big engines would benefit the most from rough surfaces that increase air velocity in the outer zone and reduce the inner zone velocity for less variation of air velocities and consequent atomizations. Another Possibility What About Perpendicular Grooves? My seat-of-the-pants testing was that it was beneficial to engine power (Suzuki AX100) and I would recommend that over just roughing up the surface. It may be that this is better at preventing fuel streaming along the surface, better than just having a rough surface. I had different cylinders and I created surface dimples on the other one and didnt feel as big a positive change as with making grooves. I just used a rotary tool to cut the grooves.  |