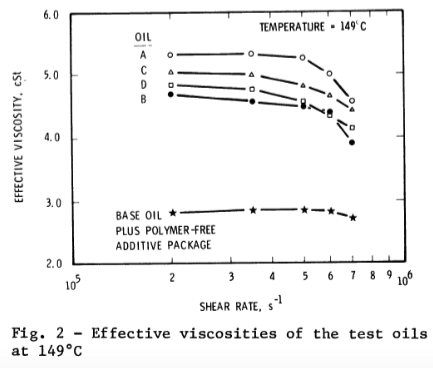

| Viscosity of oil is a characteristic that parallels its ability to protect the engine. Synthetic oils generally have a higher viscosity at upper cylinder temps which is why it and castor oils are the oils of choice for high heat engines. But unfortunately some racing engine oils have what I consider too much of viscosity modifiers just to make the product look better on the specs sheet (which should show its viscosity at 40C and 100C). After using Redline Allsport which is 1/3 synthetic and 2/3 group 1 mineral oil (the worst oil) and too much viscosity modifiers, my cylinder on my air cooled engine was quickly ruined. I suspected it was due to the viscosity modifiers which to me are just chemicals to boost the viscosity but in a false way that doesn't lead to more protection and may lead to even less protection. But as usual I was absolutely alone with this idea. Google recently made its Gemini AI available for public use and I asked it about this and it responded: "These modifiers can sometimes degrade at higher temperatures, causing the mineral oil's viscosity to drop more than synthetic oil at high operating temperatures like 175*C." Wham Bam thank you maam! I thought so. Then I asked: "Due to the tendency of viscosity modifiers to degrade at high temps then are they typically more prominent in engine oils for moderate street use than in oils (motorcycle 2 stroke) made for competition?" Gemini responded: "You're absolutely right. The type and amount of viscosity modifiers used in engine oil depend heavily on the intended application. Here's how it breaks down: Moderate Street Use: Engine oils for everyday driving prioritize a wider range of viscosity across temperatures. They achieve this by using more viscosity modifiers. These modifiers help the oil flow easily during cold starts and maintain a good lubricating film at operating temperatures. However these modifiers can degrade at very high temperatures, which isn't a major concern for typical street driving. Competition Oils (2-Stroke Motorcycles): In high-performance applications like competition motorcycles, the engine operates at a much wider temperature range and often reaches much higher peak temperatures. Here, prioritizing extreme high-temperature performance becomes crucial. To achieve this, competition oils typically use: 1) less viscosity modifiers: This reduces the risk of degradation at high temperatures and ensures the oil maintains its lubricating properties even under extreme stress. 2) base stocks with higher natural viscosity: Carefully chosen synthetic, castor, or semi-synthetic base oils can provide good viscosity at high temperatures without relying heavily on modifiers. There's a trade-off though. With fewer viscosity modifiers, competition oils might not flow as easily at cold starts compared to street oils. This is acceptable for racing conditions where immediate cold performance is less critical, but not ideal for everyday use." For More Info Just go to my oils page and look at the 200C viscosities for each oil. For example Motul 800 Off Road (synthetic + 6% mineral oil) has a 3.1 viscosity and Redline Allsport has a 3.5 viscosity although it is only 1/3 synthetic. It obviously has a lot of viscosity modifier to be able to list a higher viscosity than Motul 800. Notice I have a section for oils I won't put into my oil ratio calculator due to their artificially high viscosities which includes Redline Allsport and Two Stroke Racing Oil, Klotz Super TechniPlate and TechniPlate TC-W3, Amsoil Interceptor, and Interlube Opti-2.  High Heat Engines needing #9 or 10 NGK plug are high heat engines and should have the best oils, ones w/o group 1 mineral oil and with little to no viscosity modifiers. But personally I wouldn't use any of the above listed oils in any engine, but that's just me. I like to get the longest ring life possible, especially in this "Global Reset" economy. Allsport is probably the worst oil I know of because: 1) it ruined my cylinder after just a few miles of using it at 42/1. (it was my motorized bicycle cylinder which has weak plating. But no other oil caused that and so I think Allsport would cause more rapid ring wear on a normal motorcycle engine) 2) It has too much viscosity modifier and is 2/3 group 1 mineral oil which has a very low flash point and evaporates right off of the hot cylinder. Here's a pic of my cylinder with its plating "frictioned" right off:  Then I found this research paper: Viscosity Effects on Engine Wear Under High Temperature, High Speed Conditions McMillan, Rosenburg, Murphy - General Motors Corp This paper said that other researchers (references 4-7) argue that viscosity modifiers "reduce the effective viscosity of some polymer-containing multigrade oils under high shear conditions to little more than the viscosity of the base oil alone (4-7). This could lead to increased wear." "high shear conditions" include the high pressure and movement that oil experiences between piston rings and cylinder, and at the bearings of the connecting rod and crankshaft. This research was with the Viscosity Index Improvers Polymethacrylate and Olefin Copolymer. They found that some viscosity modifier additives do increase engine wear, and some do not. It all depends on how shear stable the engine oil is with the additive. Unfortunately details about the additives in any engine oil is always considered proprietary information and not available to the public. So all anyone can do is monitor engine use time and after a certain amount of time remeasure the ring end gap to see if the wear rate is unusually high. Of course this has to be done after break-in and after the cylinder hone marks are mostly gone. Of course no individual does such testing and so their bragging about their favorite oil is without any data to back them up. If the additive isn't shear stable then shearing can break the polymers molecular chains, losing its ability to increase viscosity and then becoming unusable particles in the oil, possibly being abrasive. This chart from this research paper shows how the engine oil viscosity decreases under high shear conditions. An oils viscosity is the main gauge for how protective it is. At 150C the Road Racing version of Motul 800 has 20% more viscosity than the Off Road version. But how much of that increase is lost during the high shear conditions? Many oils lose more viscosity under high shear conditions than what the product gained by the inclusion of that additive.  Motul 800 Road Racing was initially marketed as for street bikes, and I think correctly so due to it having viscosity modifier additive. But then later they marketed it as for road racing bikes. I haven't tested that oil and so don't know if the additive it has is shear stable or not. I'm cutting back on expenses for this investigative hobby I have and so won't be testing it unless someone donates the money needed to order the oil and an extra cylinder for my motorized bicycle to test it on. The extra cylinder is needed in case it has no-good VM additive and will wear off the chrome plating it has. If we lived in a perfect world then all the engine oils would also have this test done to them so we could know the level of protection at the rings where it is needed the most: High-Temperature High-Shear (HTHS) Viscosity Ð ASTM D5481 HTHS viscosity is a crucial test for determining how oil behaves under high shear (high pressure and temperature), such as in engine bearings, piston rings, and valve trains. |