|

I was dissatisfied with the common suggestions for different port durations [with the "blowdown" being from exhaust opening to transfer opening] for different top RPM because they didn't take into account the exhaust port shape and size which determines the length of time that high pressure exists in the cylinder. That pressure has to be near zero before the intake charge can go thru the transfers into the cylinder. At high RPM if the transfers begin to open while there is still more than 5psi in the cylinder then the transfer of intake charge into the cylinder is delayed. TRANSFER TIME-AREA? Previous calculators depended on the calculated time-area of the ports. This is inaccurate for many reasons. The most important thing is the loop flow of intake charge. When there is excess time due to low RPM then some of the intake charge is lost out the exhaust port. When there is too little time then the flow doesn't reach the exhaust port and so it's unable to push out as much spent gases from the previous cycle. There is a resonant RPM for each engine depending on crankcase pressure and loop distance. If the engine is designed so that the resonant RPM is the same as the wanted peak power RPM then the maximum power possible is acheived. My porting program calculates the % delivery ratio for each 250RPM up to the max RPM.

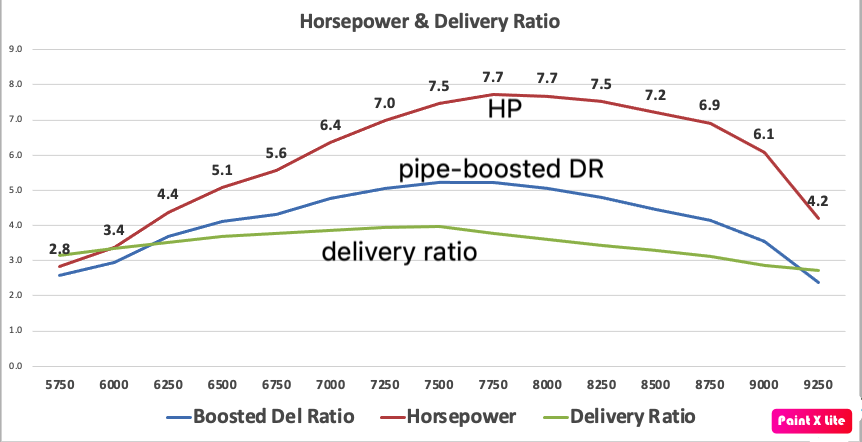

How does the expansion chamber help or hinder the engines peak power RPM? Imagine two hill-like power graphs. One is for the delivery ratio and one is for the pipe powerband. Only if the two overlap correctly will the final result be the maximum power/powerband available from the engine. So it is really important to design the porting for the desired engine peak power RPM and then design the pipe so its powerband middle is at the portings peak power RPM. Then the two will be in harmony with each other.

Can too high an exhaust port be detrimental? Yes. I have done many tests with many different porting arrangements and when an exhaust port has a longer duration than needed it has less power and sometimes even less peak RPM. Why? Because the higher the port, the less trapped cylinder volume there is above the port (making the actual engine size smaller) and the more intake charge can be lost out the port. |