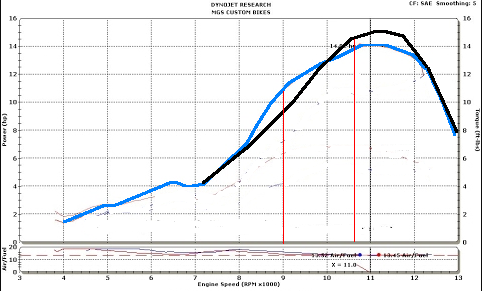

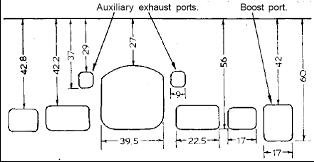

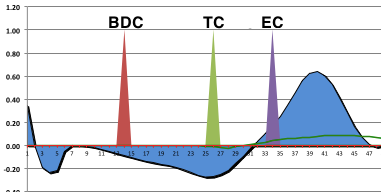

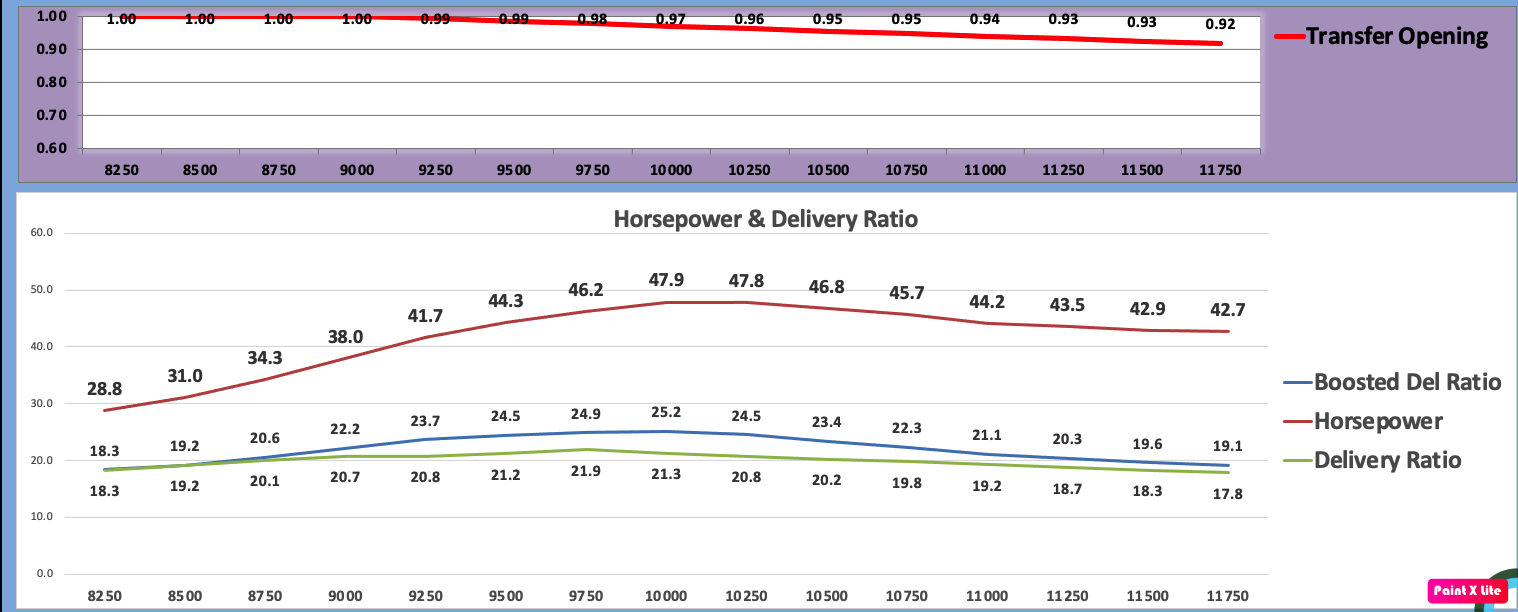

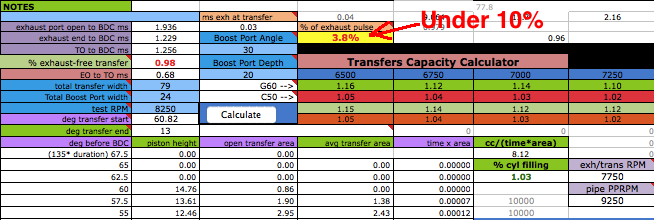

| Rule #1: There's more or less a set amount of power available for you to manipulate. If you port for high RPM power then your low/mid-range power will suffer. You are robbing Peter to pay Paul. In the example below the blue graph shows a porting power peak at 9000 RPM and the black graph shows a porting power peak at 10,700 RPM although they both have the same beginning and end due to the same pipe. The black horsepower would be better for drag racing, and the blue horsepower for motocross and trail riding.  Rule #2: You are pretty much stuck with the transfer porting arrangement the factory put in your cylinder other than changing their heights. If your transfers have limited area then you can only widen them a little to the rear which won't make any big difference in power. If the exhaust port is single with no auxiliary ports then you are usually stuck with that but you can widen it to 75% of the bore. A very few people have drilled in their own auxiliary ports but usually there isn't enough thickness of aluminum there to do it.  Rule #3: Widening the exhaust port or making it more square at the top will shorten the lifespan of your rings. So when you gain something you lose something. But the more square it is at the top the better the top RPM power is although with some loss of mid/low range power. And that increases the exhaust noise  Rule #4: The expansion chamber controls the top RPM, not the porting. Porting can only move the power up or down. If you want to increase top RPM you have to shorten the header of the expansion chamber. But only with a good expansion chamber calculator will you know how much to shorten it by. The graphic below shows the relation of the pipes return waves with transfers closing (TC) and exhaust closing (EC) timing. At what RPM those waves have that alignment is dependent on the pipe cones distance from the cylinder.  Rule #5: Blowdown degrees are only half of the equation. Avoid charts that emphasize them without any mention of port size. True blowdown is the time it takes for the combustion pressure to fall to near zero so the intake charge can enter the cylinder freely. This is where computers come in. Depending on the piston speed (due to RPM and stroke) the time it takes can be calculated according to the open port area every millimeter down as the piston uncovers the port. This can show if you need more area/degrees between exhaust port opening and transfers opening. You can increase the area by widening the port or making the top half of it more squarish, or increase the degrees by raising the top of the exhaust port. And a computer can remove any guesswork on how much to do. Widening is preferable because raising the exhaust port reduces the trapped volume of the engine, effectively making it a smaller engine. Only the area above the exhaust port is the true engine size. For some fucked up reason the same formula for 4 strokes is used on 2 strokes for their engine size which is the volume the piston displaces from BDC to TDC. It's totally wrong for 2 strokes. Here is a free spreadsheet that allows calculation of your engines trapped volume: www.dragonfly75.com/moto/various.html The graph below is from my porting calculator which shows the limited opening of the transfers (1st graph) and the delivery ratio, torque, and horsepower. You can also see where the delivery ratio has its peak, which in this example is at 9750RPM.  Rule #6: The exhaust port location and size is only relevant in relation to the transfer ports. If the exhaust port is too narrow or too low then at high RPM the pressure will still be present when the transfer of intake charge wants to happen. Delaying transfer flow might reduce top RPM power. A good porting calculator will help you figure out if anything needs to be done with the exhaust port according to the designated top RPM. My best estimation is that 10% of the exhaust pressure time is the maximum amount of overlap of transfers opening you should allow at the portings peak power RPM.  Rule #7: Porting is not the end all. Just as important is the crankcase compression ratio, jetting, the reed petal tension, the lack of air intake restriction, the squish volume and velocity, quality of fuel and engine oil, the ignition timing, and the design of expansion chamber which can either emphasize a narrow powerband with high peak power, or a broad powerband with lower peak power. If you want to port for more emphasis on high RPM power you don't know whether to raise the exhaust port, raise the transfer ports, or raise both. This is where a good porting calculator comes in. It will tell you if you have adequate separation between the exhaust and transfer ports with your current setup. To read more on this topic go to http://www.dragonfly75.com/moto/porting.html |