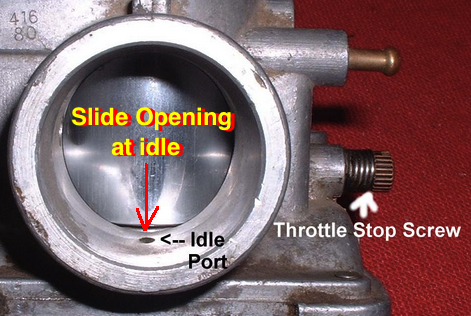

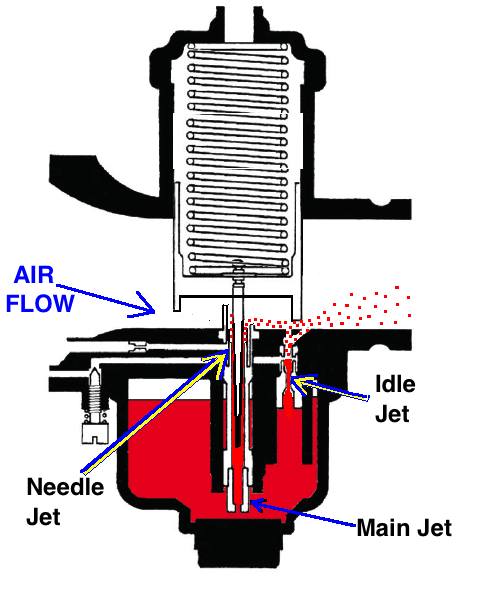

SIGNIFICANCE OF IDLE SLIDE OPENING An opening of between 8% to 12% of carb bore is typical of a well tuned carb (including idle jet, needle, needle jet, slide cutaway). So for a 28mm carb the vertical space under the front of the slide should be between 2.2mm to 3.4mm if it is tuned right and adjusted for a normal idle speed. Before continuing you need to know that about 40% of the idle gasoline does come up past the needle jet at idle. If you don't believe me just clog the main jet and then see how the bike changes idle. It probably won't idle at all. So the slide height at idle affects 1) how much gas is pulled up thru the idle jet. The lower it is the faster the air speed and more vacuum right there. 2) how much gas is pulled up thru the needle jet (the hole the needle fits into). The lower the slide the less gas is pulled up.So a low slide activates the idle jet more and the needle jet less. And a high slide activates the needle jet more and the idle jet less. So if the slide is less than 8% open at idle then probably the needle jet is too open (the clearance between needle + N.Jet is excessive) or the needle shroud is too high (which activates the needle jet more), or the idle jet is too small. 250cc and larger engines vibrate enough for the needle to wallow out the needle jet for excess clearance and in that case the N.Jet needs to be replaced. A high slide indicates either the idle jet is too big or the needle/N.Jet clearance is too small. MEASURING THE SLIDE OPEN I just use an Allen wrench set that has small sizes every .5mm and then guesstimate the distance when not even with it. Of course before analyzing the carb for idle you need to make sure compression is good, crank seals aren't leaking, and the reeds aren't frayed. EXAMPLE A 38mm Mikuni carb on a Maico 250 piston port had only 1.1mm opening for idle. That is only 3%. Looking over the rest of the details of the carb I saw that it had a 8mm high needle shroud which is mostly only for reed valved engines since their suction wave increases very gently, not abruptly as with a piston port engine. The needle/N.Jet clearance wasn't excessive so that wasn't part of the problem. I advised him to cut off the shroud and increase the main jet (because the extra suction the shroud captures affects both the needle jet and main jet) and if that then causes the mid throttle jetting to be lean then install a needle with more taper angle (such as 6DH7 or 6DL30) to replace the present 6F5. STEPS TO TAKE If the transition from idle to mid throttle is good then leave it alone. Otherwise, if the slide is high and off idle is lean (it bogs if the throttle isn't slowly opened) then consider a thinner needle or larger needle jet to allow more gas flow there. If not lean off idle then just go to a smaller idle jet. If the slide is low and off idle is rich then consider a fatter needle or skinnier N.Jet. If not rich then just put in a bigger idle jet.  |