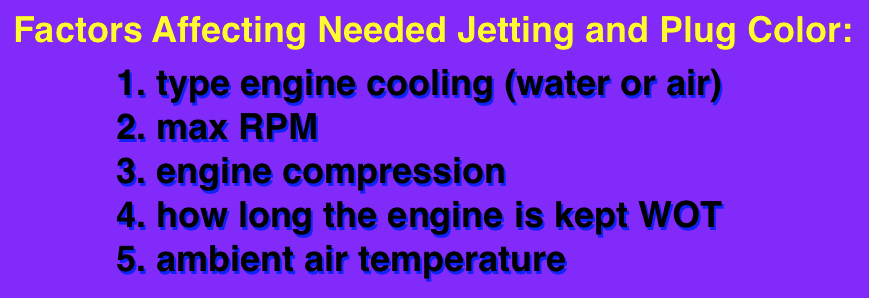

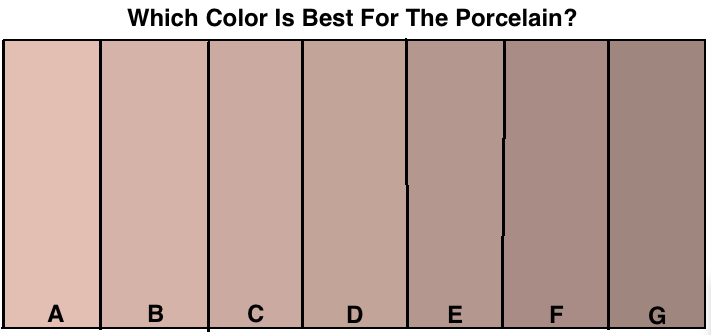

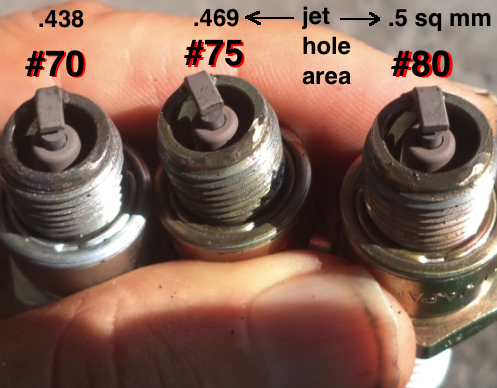

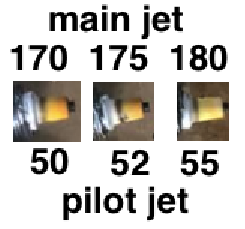

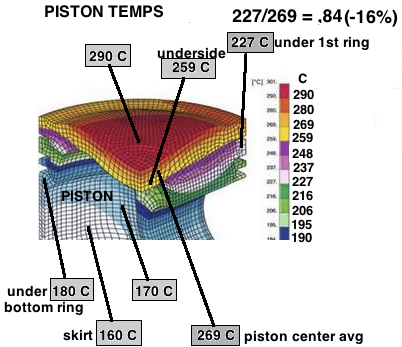

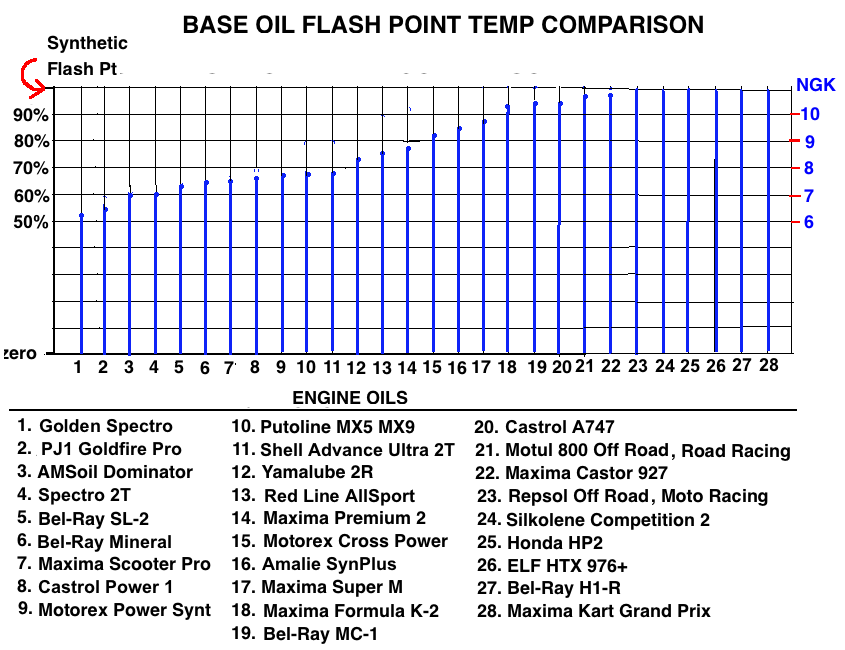

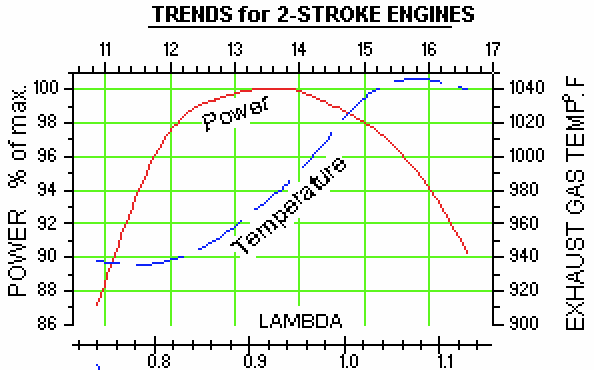

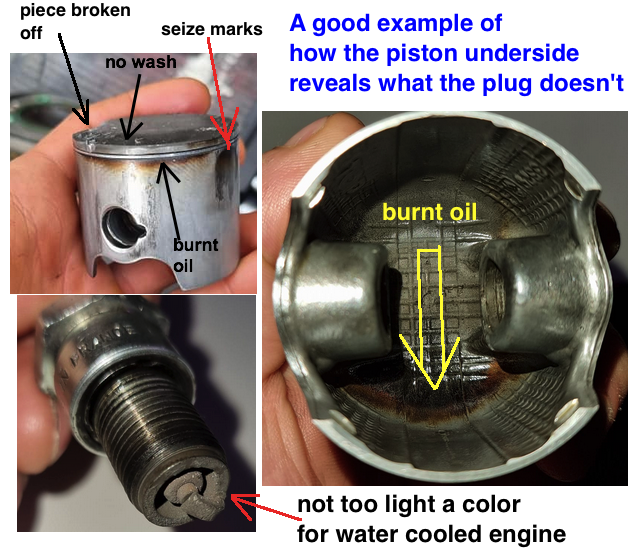

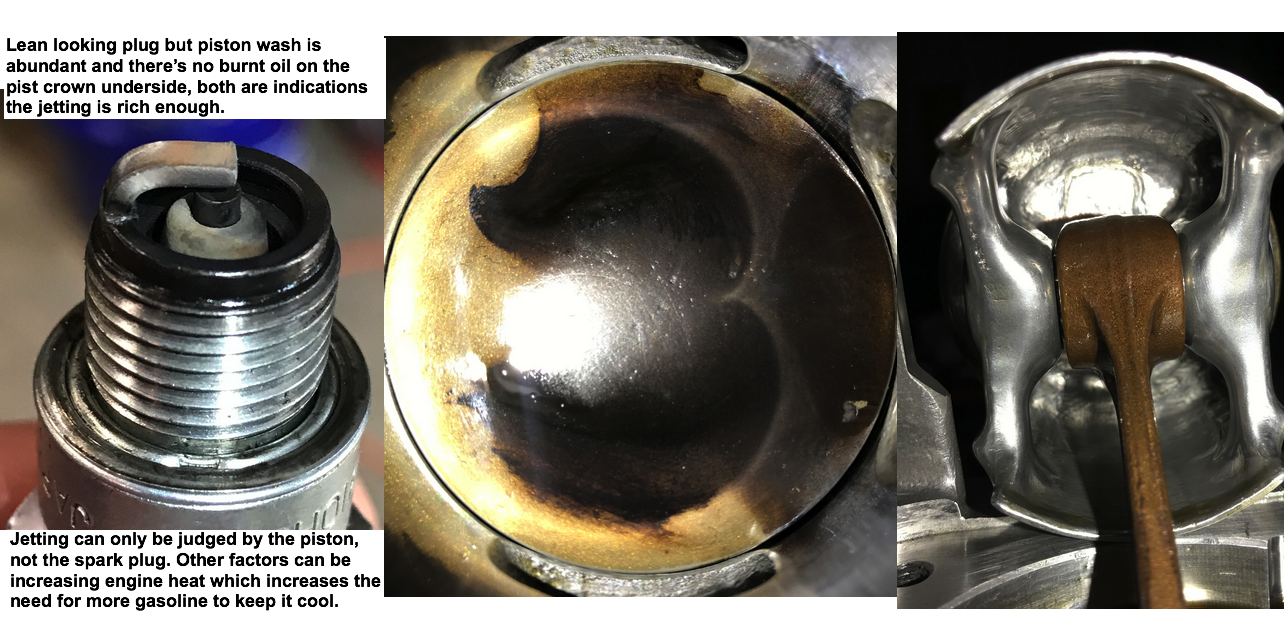

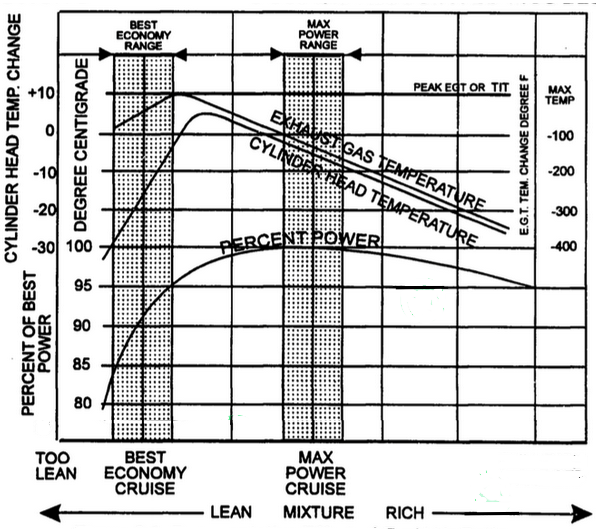

| Important Quotes: Gordon Jennings, The Two-Stroke Tuner's Handbook "The plug's insulator nose color is a very poor indicator of the overall air-fuel ratio... Jet for maximum power on the dyno or track; plug reads are secondary and often misleading due to oil and heat variations." Gordon P. Blair, The Basic Design of Two-Stroke Engines "Spark plug color is influenced too much by oil and additives to be reliable for jetting; tune for peak torque/power via dynamometer testing, with EGT as a secondary metric for safety."  Carburetor jetting is about getting maximum power without seizing, not about plug color. You can acheive both goals but it gets harder as the engine becomes more high performance. The more high strung an engine is, the more synthetic the engine oil has to be and the more needs to be added. There are many oils that are promoted as being fully synthetic but they aren't. To see the real % of synthetic and mineral oil in each engine oil click here. To know which oil to use based on spark plug heat range (which lets you know how much heat stress it has) click here.   The plug color and the lower ceramic color band is an indication of jetting but still tells nothing about power or piston heat which are the main two criteria for jetting. Those plug readings have some relation to piston heat but aren't directly related to it or the heat limitation of the engine oil you are using. The correct plug color varies according to many factors. There is no such thing as a universally correct plug color or color band width at the base of the plug ceramic. This page is about a universal method of jetting which is equally good for all 2 stroke engines.  If I asked 7 different riders to pick a "correct" color below then I'd get 7 different answers.  And have you thought of the fact that color lightness/darkness depends on the light hitting the plug? Observe it in the shade and then in the sunlight and you'll see two different shades of darkness of color. So even if it were possible to have one universal color that is right, then that color should only be looked for under a lamp of a prescribed light intensity (which isn't going to happen). The Test I did a test with 3 new NGK plugs, 3 original main jets (#70, 75,80), one long uphill, and killed the engine at the top after each WOT run. The engine was a 48cc air cooled with 8.2 compression ratio, Mikuni 16mm carb, expansion chamber with holed baffle, using Motul 510 (2/3 mineral oil) at 28/1. The #80 jet has 14% more hole area than the #70 jet and in my jetting calculator it said the equivalent flow area with the needle clearance figured in also was a 8% difference. Can you see any difference in color in the photo below? My naked eye could see the very faintest of increased darkness in the plug that used the #80 jet. Conclusion- there is no way on Earth that plug reading is specific enough to be useful to select a main jet. That is nothing but wishful thinking for lazy people.  Plug "Chops" And looking at the ceramic ring is just as useless because in this case the rings would all be the same. Rings change as the plug color changes and in this case the color didn't really change. So the porcelain ring would of been the same too. Proof of that assumption came from someone who shared the pics below of plugs with the threads cut off to see all the porcelain. The widths of the dark bands were all the same.  Piston Wash Is looking at the piston wash relevant? Somewhat, but not the best measure because that depends somewhat on crankcase compression which controls the speed of transfer flow, and the roof angle of the transfers, whether the piston is flat or domed, and the size of the carburetor (which determines the % of large fuel droplets). The idea here is to have a certain % of the top area mostly clean due to the cool air/gasoline mixture contacting that area of the piston and keeping it too cool to let engine oil burn onto it. This picture shows the most common "correct wash area" for a domed piston:  The Pro Method Here's what is best to do: Find out the jetting for the best power under both "low load" (flat/hard road) and "high load" (uphill, sand, mud, etc) which should show as the highest speed or best acceleration. Then choose a main jet between thos two extremes. If you don't normally experience a high load riding situation then just test for low load. When testing don't do overly long runs, just long enough to gauge engine performance. My 48cc liked a #82.5 main jet for flat roads, and a #90 for uphills, so I can use a #85 if most of my riding is on flat/hard terrain, or a #87.5 if over half my time I am riding hills. Relation of Piston Wash To Piston Underside In the two pics of the same piston below we see it had some oil burning onto its underside although the piston wash looked almost ideal. He then should of increased the main jet or switched to a more synthetic engine oil (since synthetic oil is more resistant to burning and will continue lubricating instead of evaporating off the cylinder).  The Importance of Oil The idea here is that the piston at the ring lands is around 16% less hot than under the piston crown and so when the oil is just burning a little at the piston underside then the oil is probably evaporating off at the rings at the hot upper cylinder, leaving it unprotected. Then the increased friction raises the temperature all along the skirt and some of the aluminum melts onto the cylinder, which is what happens when a piston seizes. The oils most resistent to burning are the castor and synthetic oils. They should always be used for hard racing. As some backup for what I'm saying there is this on-line info : "Castrol Power1 XR77 is a synthetic oil specifically developed for pre-mix use in racing 2 stroke motorcycle and kart engines. It has a high lubricity formulation to prevent seizure in high speed conditions - allows tuners to lean out their engines to a maximum". https://www.livapetrol.com/en/home/4626-castrol-power-1-xr-77.html  What makes this condition variable is the different flash point temperatures of different oils. No, I'm not talking about the flash point of the whole product which is a listed data point. That doesn't count because that results from the combination of base oils and the kerosene-like solvent that was added to the mix to make the product more pourable. I don't care at what temp the solvent evaporates off. Most synthetic oils (group 4 + 5) evaporate off at 252 degrees celsius (486F) or higher. Group 2 oil (moderately refined petroleum oil) evaporates off around 218C (428F), and group 1 oil around 70C (which is very low and will instantly evaporate off cylinder walls). By the CAS # of the base oil (listed in the products safety data sheet) you can see each ones flash temp listed on this page. Of course there is a big difference between 218 and 252C so for the best protection for racers I wouldn't use an oil with an average much less than what pure synthetics offer. Here's my analysis of some products I could find enough data on their base oils. For example Dominator only has a base oil flash point average of 58% of that of a full synthetic oil. But it usually is OK for trail riding and amateur motocross because of the limited time that the throttle is wide open. The greater the % time of WOT running, the better oil you need to use. This chart allows you to choose an oil based on your NGK #. Don't use an oil more than one horizontal section lower than the plug #.  Of course my best recommendation is for racers to use a castor/synthetic blend like Castor 927 by Maxima. No, I don't know its flash point average because I can't find the flash point for castor oil but I suspect it's as high if not higher than for a synthetic oil. It has a tendency to increase its protection as temps rise. And it doesn't cause gumming up of the ring lands unless the engine is getting nearly hot enough to seize. Husqvarna did some testing in the mid 70's that was very interesting. They put 3 identical stock engines on a dyno and ran them for several days at varying RPM and load conditions. Then the motors were torn down and inspected. The engine running CASTOR based oil had the least wear, followed by the synthetic oil, and finally the engine running standard 2-cycle mineral oil.  Reasons there is no "one size fits all" single best temperature with EGT : 1. Comparing EGT readings between engines whose EGT probes are not mounted exactly the same distance from the piston will get you in trouble. The closer to the engine, the higher the readings. 2. EGT climbs as the RPM comes up which means different readings are to be expected with different engines of different top RPM. 3. Charts differ as to how much less than peak EGT temp you need to be at for peak power, so you can't really rely on them. You have to know your particular engine. You have to first find peak engine power by trial and error and then note the EGT for future reference.  Oil Quantity Can Sub For A More Synthetic Oil Just don't add so much that you foul a plug too quick if the oil has some group 1 & 2 oils in it. Husqvarna did a test running synthetic in 2 identical engines and one was run at 24:1, the other was run at 50:1 The engine that ran 24:1 had less piston skirt wear, and less rod bearing wear. This is the routine I'd recommend: 1) find the main jet that gives the best power under load. 2) take the engine apart and check if under the piston underside it's black. If it's brown and can be wiped off by your finger then don't worry. 3) if it's a sizeable spot and very black then you should put in a richer main jet or a more synthetic oil or increase the amount of oil you add to gas. Engine oils with group 1 oil can cause blackness although the engine heat is acceptable which is one reason I warn against using products that contain group 1 oil. 4) after running it with the correct main jet WOT (cut the engine at the end of a straight) take pictures of the piston top for a future point of reference so you don't have to completely take apart the engine each time. Or while riding WOT take one of these measurements: AFR, EGT, CHT. my video on this subject: 2 Stroke Main Jet Sizing Important Quotes: "To a large extent, the cylinder wall temperature also determines the lubricant temperature in the contact of the top compression ring" http://www.sciencedirect.com/science/article/pii/S0306261917301022 "flash temperature parameter (FTP) is a single number that is used to express the critical flash temperature at which an engine oil will fail under selected conditions." http://pubs.rsc.org/en/content/articlehtml/2017/ra/c7ra00357a These are pictures from a failed engine. Probably the excessively hot piston allowed the ring end pin to come out and break off a piece of the piston. The plug has a nice color but the piston underside shows a black area where the piston was too hot. The owner used synthetic oil at 40:1 and since he can't much improve on that he needs to jet a little richer (do power tests with different jets).  Jetting Effects on Piston Color On my air cooled 48cc it ran the strongest with a #72 main jet but both the #76 and #72 left some brown residue under the piston top but it wasn't burned black. So the Motul 710 oil I used was synthetic enough to not burn there, just evaporate/condense. Their piston tops were both without wash but that was because the transfer roofs had a terrible angle close to 45 degrees which allowed little to no large fuel droplets to contact the piston top to cool it and leave wash areas. This test confirms though that leaner jetting produces darker piston tops due to the excess heat because the #72 piston was darker.  Plug heat range in relation to actual engine heat affect plug color more than anything. This plug has a very light color because it got too hot due to the owner selecting the wrong heat range plug. The light color might have fooled the owner to down-size the main jet which would of been disastrous.  Here's visual proof that different % content of mineral oil in a product affects how darkly the spark plug will be colored. Dominator (left plug) is 45% group 1 mineral oil, and Super Techniplate is mostly synthetic and 20% castor oil.  Flat Topped Pistons Being flat makes the top piston surface farther away from the incoming intake charge coming thru the transfer ports and so the result is less wash area.  This graph generalizes the idea that up to a certain point the temperatures get hotter as the jetting mix gets leaner. As piston heat increases, the amount of oil that burns onto it increases. When it is so hot that the underside is burning oil onto it then the cylinder will probably be hot enough to vaporize the oil off it which increases ring friction which increases heat and the piston melts and seizes in the cylinder.  My parting words on this page is to let you know that the richer the mixture is, the slower the burn. So a richer mix may need more timing advance. So please jet according to the advice on this page and then try different timing settings to see how it affects the powerband. Generally more advanced benefits mid range power, and more retarded benefits high RPM power. Even with a rich mixture, if you advance the timing too much you can cause detonation, so be careful. |