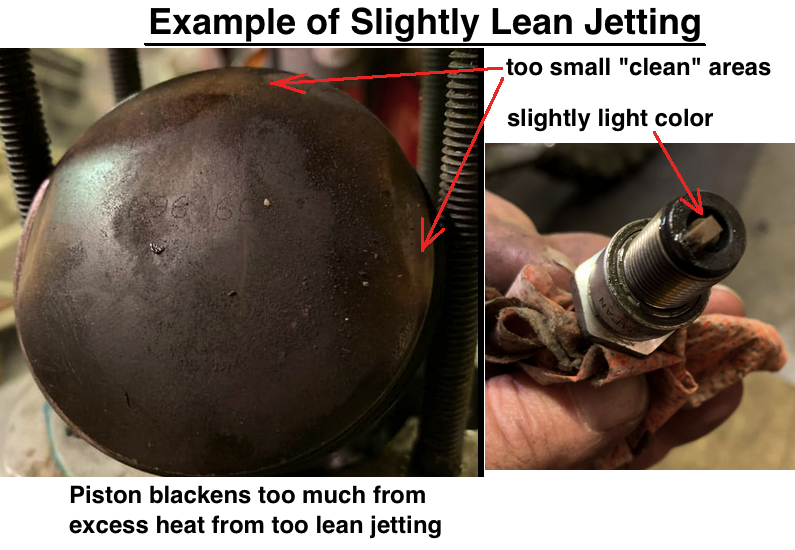

| Plug color is affected by engine oil, fuel, RPM, compression, and plug heat range which is why it's not good for checking whether the main jet is too rich or too lean. The correct main jet size is that which allows the best power at WOT. And there are a few ways to judge the jetting due to needle taper and needle height including: 1) how the exhaust note sounds, 2) how the engine responds to quick throttle opening, 3) how the power is going uphill and downhill. Useful Plug Indications EXTREME COLORING: Really dark or really light is an indication that you are clueless as to reading the feel of the engine and the exhaust note, because if you were good at that then you wouldn't even be looking at the plug. But if that is what you are doing then read the color on the first half of the ground electrode (not at its end) and end of the ceramic insulator. Medium gray or medium chocolate brown is the ideal color. This plug shows a good medium color. I was using Castor 927 engine oil at 40:1. But keep in mind that this was on an air cooled engine that runs hot and needs more gasoline for cooling. I expect a water cooled engine can have a slightly lighter colored plug that indicates leaner jetting.  White colored ceramic insulators are caused by 1) too lean a fuel/air mixture 2) too hot a rating for the plug Gray (not brown) colored plugs can be caused by 1) use of aviation fuel 2) use of certain synthetic oils Dark plug color can be caused by 1) excessive amounts of oil added to the gas (mostly with group 1 and 2 oils otherwise known as mineral oils. (Click here to see what group oils are in the most popular 2 stroke engine oils) 2) too rich jetting 3) spark plug misfiring possibly due to bad electrical connections or a failing ignition component (CDI, high voltage coil, stator coil) 4) too cold a heat rating for the plug (too low a NGK #)  Below you can see how this piston is just one step away from the oil burning black onto its underside. This is as hot as you want to let it get. If it is black then the jetting is too lean.  Be warned about lack of coloration at the side end of the center electrode that is more than a half millimeter. That is caused by too much spark advance or too hot a plug rating. Enough spark retardation allows all of the sides of the metal electrode except for the last half millimeter to have combustion deposits on it.  Cheap gasoline without enough deposit control additives can leave strange deposits on the plug. This is fairly common in 3rd world countries but also happens in 1st world countries. (see https://www.knowyourparts.com/technical-resources/engine/how-to-prevent-engine-deposits/) How To Test The Main Jet If you look at the dynometer graph below it shows the air-fuel ratio going rich before and after the meaty part of the powerband. So ideally you want to spend most of the time in that part of the powerband while testing the main jetting. You can ride on flat ground and keep upshifting and then in top gear apply the brakes to keep the engine from reving much past the meaty part of the powerband. Or you can ride up a long incline to keep the engine from reving past the sweet zone. If the main jet isn't too lean then you can get enough color on it to read it within one mile. If it is too lean then it may take 5 miles.  Reading The Ground Electrode If the plug heat range is correct then there will be a shift in color about at the halfway mark along the ground electrode. If that change happens closer to the plug body then the heat range # is too little. Here is my test result for the same engine with plug changes within a short span of time. The color change was almost too faint but it was there. The #7 had its line right at the halfway mark so it is the right plug for this engine. The extra black body base of #6 is because I had been using that plug previously a bit and so had more run time on it. The oil used was Castor 927.  |