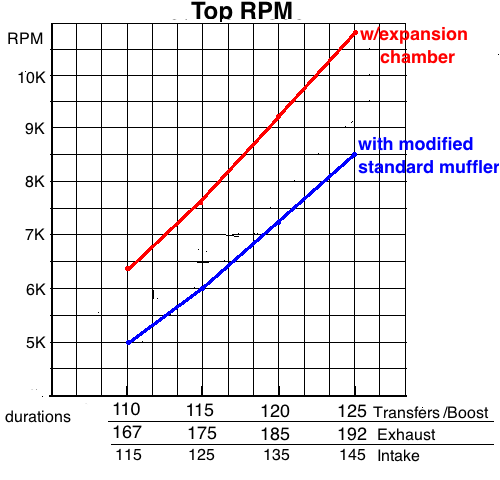

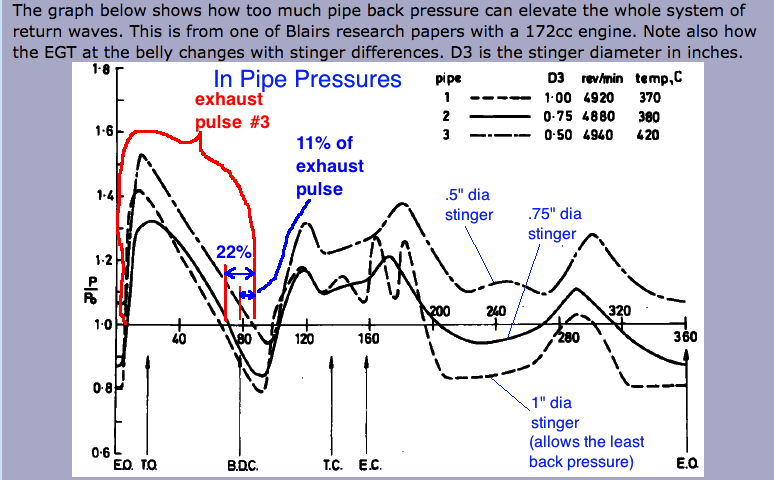

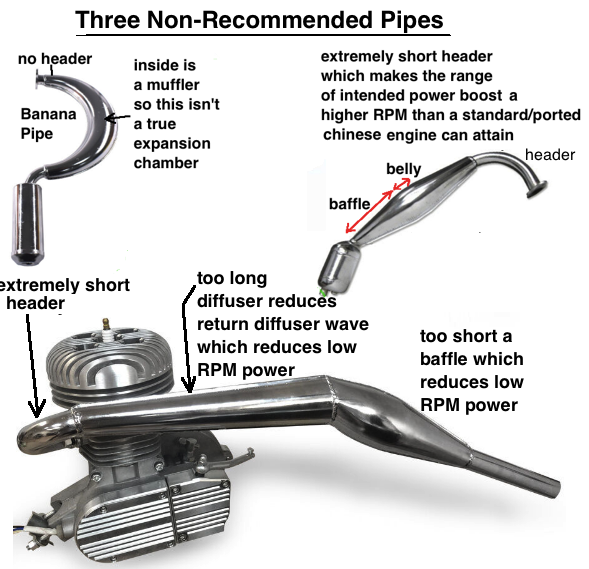

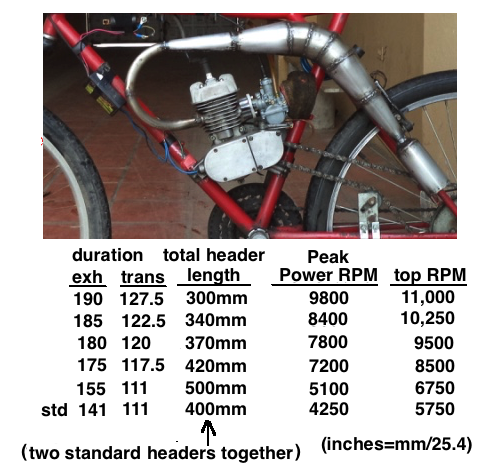

| Matching Pipe Design to Engine Porting (or vice reversa) Before getting into pipe design you first need to know that there are two powerbands, that of the engine (via port durations) and of the pipe (via length to baffle). If they synchronize then you get the best power. If the pipe powerband is much higher than the engine powerband then it is easier to ride on the street or trail due to good low RPM power (below the pipe powerband) but it will be down on peak power. But if the engines peak power RPM coincides with the RPM of the middle of the pipe powerband then you get the highest peak power which is desirable for racing. It is also desirable for small engines since they are naturally down on power due to their size. This chart is only for the 48cc and 66cc chinese engines with exhaust port widened to 70% of bore (measured straight across).  Use this formula to find your end of pipe powerband: top RPM = (exh duration x 40800) / length in mm from piston to beginning of baffle cone or in inches: top RPM = (exh duration x 1606) / length in inches from piston to beginning of baffle cone mm = inches x 25.4 inches = mm / 25.4 Look at this pressure trace from a sensor inside the beginning of the header. It's from one of Blairs research papers. You can see the exhaust pressure pulse (look at the biggest one). The pressure at the beginning of the last 22% of that is what exists right as the transfers are opening with 26 degrees blowdown at 7900 RPM with durations 175/122.5 but if you increase the blowdown just 2.5 degrees more (175/117.5) the pressure will be at the 11% mark which is a low enough pressure. When there is too much combustion pressure when the transfers open there is too violent a squirting of the exhaust gas into the transfer channel to mix with the intake charge there. That is totally undesirable. These calculations are just for these standard chinese engines. Less blowdown is needed for engines with larger exhaust ports such as is typical today on high performance engines.  In the motorized bicycle world people have been making the mistake of putting high RPM motocross pipes on these low RPM engines. Those pipes only help a little with reed valve engines because unless the cylinder is drastically ported it will never reach the high RPM of the pipe powerband. Stock MB engines rev to around 6000 RPM but the pipes for motocross bikes (such as KX85) kick in at 9400 and go to 12,500. But the stock engine isn't ported to get up into that high range. And if you did port it to do that then it will be gutless at low RPM and you'll have to embarass yourself and pedal each time to get it going. Porting just to have a peak power RPM of 9000 is 122 transfer duration and 190 exhaust duration which is as high as you want to make these ports. Some people have remedied that problem by welding in long tubes at the beginning of the header section to lower the pipes power range. Typical is a 5 inch length. But then there's the additional problem of the pipe having a short powerband because it was designed for an engine with a 6 speed gearbox. It's only 1500 RPM long when adapted to these chinese engines. It can be stretched to 2000 if the belly is lengthed 2 inches and the baffle cone increased (by replacement) 4 inches. (I know all this by using my pipe calculator). But if you are going to go to all that trouble then you might as well just build a pipe from scratch that is beautifully contoured to match you bicycle and not be an eyesore like those motocross pipes are. About 4 different "expansion chamber" pipes are sold for these engines but none of them are any good, trust me. Pipe design has been my specialty for years, so I know what I'm talking about. Click here to see some other pipe designs (including silencers).  Here's my latest pipe of great design because it matches the pipe design to the engine powerband. The picture shows the pipe without a straight header pipe between the curved header and diffuser which is necessary for 185 and 190 exhaust durations. Belly diameter is 70mm which is just right for 69cc and a tad wide for 48cc but OK (I have it on my 48cc) according to my pipe calculator and isn't so wide as to be dangerous to your leg.

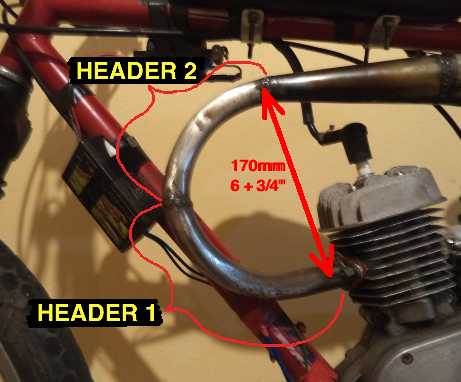

Notice the dark line half way up the header. That is where the two curved headers were welded together. The 2nd half of the header was cut from a stock pipe. Before you cut a curved section out of a stock pipe go ahead and measure from piston to end of 1st curved header. Then subtract that from the desired total to know how long the 2nd section should be. If the 2nd section can't be long enough then order a custom length of pipe from Metals Depot to go between the curved header and the diffuser. Also the stinger section can be ordered from them.  Click here for my pipe building resources page. |