|

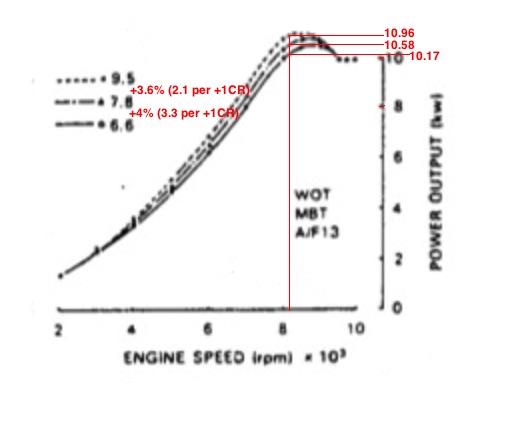

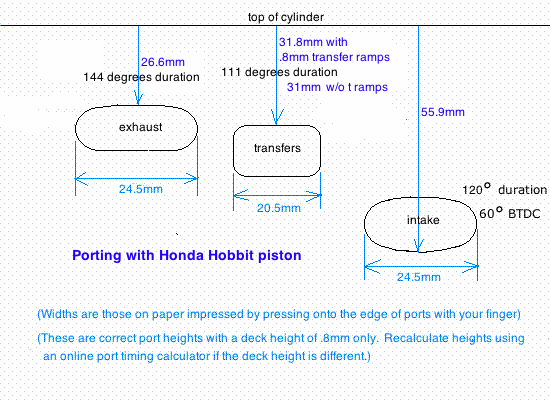

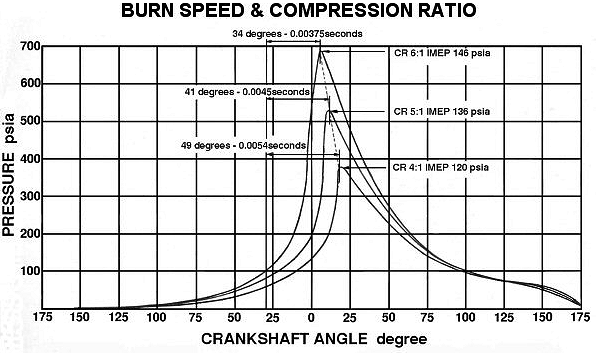

The standard Grubee engine has only between 90 and 100 psi measured compression. A significant power increase can be had by increasing it to 130 - 140 psi. The upper conrod bearing should be replaced though because the standard one can't hold up to the increased pressure of combustion. The following graph shows an increase in power output of about 5% at 8000 rpm when the compression ratio is increased from 6.6 to 9.5 to 1. It's not a lot but every bit counts when improving these engines. The percentage power increase is even more at mid range rpm which is of added importance to a one speed street machine.  There are two options for increasing compression but I donīt advise either in conjunction with a stock CDI which advances the ignition too much at high rpm. Only with a Jaguar CDI should you increase compression. That is because higher compression increases the heat load which can damage the piston if the ignition timing isn't delayed enough (which the Jaguar CDI does at high rpm). 1) Shave 1mm off the head at the mating surface to increase compression a bit (usually to around 6.5:1). For long life of the connecting rod bearings I wouldn't go higher than 7 to 1. Grinding down the head mating surface can be done at home with a 10" square piece of glass and some moderately rough sandpaper. While pressing the head on the sandpaper (which is on top of the glass) move the head in a circular pattern. Then use valve grinding compound between the head and cylinder and move the head against the cylinder in a rotary movement to more perfectly match the two together.  2) Increase the compression by replacing the piston with one that has a higher top. There is this piston from Treatland that is 1mm taller from the wrist pin than the standard 48cc piston. That is probably the perfect distance to bring the compression to around 140 psi. You may need to use your rotary tool to grind away at the head along the outer edge of the combustion area to allow at least .8mm distance between it and the piston at top position. This is cheaper than buying a high compression head and it also eliminates the problem of the excessively stiff standard rings from prematurely wearing off strips of the chrome cylinder lining. The Honda piston rings would also have their ends closer together for better sealing of the combustion area for more power. The stock rings are about 3 times farther apart than they should be. The added piston height would change the port timing though which would run terrible unless you used a rotary tool to change the exhaust and transfer port heights (see drawing below). Here are my recommendations for changing the intake timing with this piston: Intake port 55.9mm from top of cylinder to bottom of port (which gives a perfect 120 degrees duration) Piston skirt 45mm from top of piston edge to bottom middle of intake skirt. (and the exhaust side skirt needs to be reduced to 46mm to keep it from hitting the crank wheels)  This is the piston specs: Honda hobbit stock 40mm piston $30 50mm from piston edge to bottom of piston 24mm from wrist pin center to bottom of piston 26mm from wrist pin center to top edge of piston 10mm wrist pin diameter 1.5mm ring vertical thickness Another basic improvement is replacing the stock aluminum head gasket with a fiber one that works much better. Just buy gasket material from AutoZone and make your own gasket this way: 1) wet the head mating surface with oil very lightly, 2) press the head onto the gasket material so that the oil shows the head pattern on it, 3) cut out the center hole and stud holes using an exacto knife (available in hobby stores) With higher compression comes more stress on the upper connecting rod bearing. Replace it with a Stihl 028 chainsaw bearing or this one which will last much longer. Gordon Jennings wrote: "I do not concern myself

overmuch about calculated compression ratios; I prefer to work with

cranking pressures, as they give a more accurate indication of what is

happening in an engine. ... no [mass produced] 2 stroke engine in my

experience had ever tolerated cranking pressures above 175psi". At sea

level a compression ratio of 6 = 103

psi and a compression ratio of 7 = 137 psi. Click here for my free compression ratio calculator in an Excel spreadsheet. The online ones only work if the piston top is flat.

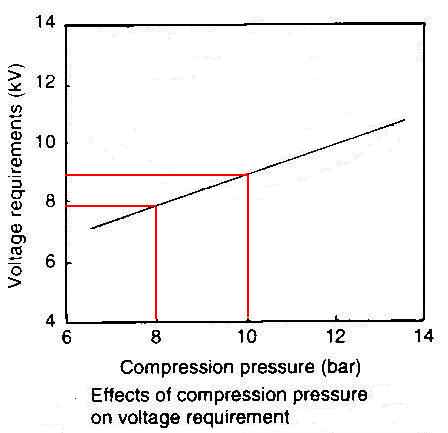

Going up in elevation lowers the psi because there is less pressure to start with, so at 3000 ft a CR of 6 = 89 psi, 7 = 110 psi, and 8 = 131 psi. At 6000 ft a CR of 9 = 132 psi. I recommend using a compression tester to see what yours is really doing since the rings on these HTs allow considerable blowby which decreases the compression. The Honda piston seals better because it has a normal ring end gap, unlike the sloppy stock Grubee piston which has 3 times the normal ring end gap. Click here to read more on about compression. Stick with the stock head instead of buying an angelfire head with an angled entrance for the spark plug unless you have to for frame clearance. I thought it would give more compression and torque because of the 6mm squish band, supposedly better than the stock zero squish band. But it gave less compression and reduced the top speed by around 5%. After researching the subject I realized that it's very important that the spark plug tip be in the intake charge flow for quick and complete combustion. The angelfire head removed the spark tip from the intake charge flow which reduced engine power. Also a squish band on any engine is a waste of time if the compression is less than 150 and/or the top rpm is less than 9000. (see below for more info). And if the vertical clearance from the piston in the band isn't very small (.6mm - .8mm) then it doesn't work at all. The Effect of Higher Compression Ratio in Two-Stroke Engines by Yuh Motoyama and Tohru Gotoh Yamaha Motor Co. "Higher compression ratio makes it possible to improve power output, but causes serious problems such as knock and piston thermal load increase. A (corrected*) compression ratio of 9.5 is the maximum limit at which knock can be avoided and power output ensured. To remedy low-load knock, the use of premium gasoline and improving cooling are effective measures. If premium gasoline is not used, the permissible limit of the compression ratio is approximately 8.4 without liquid-cooling and 8.7 with liquid-cooling." * corrected ratio is found by considering the cylinder volume above the exhaust port instead of the volume at BDC Increased Spark Voltage Need Anyone after better performance usually ups the compression of the engine but unfortunately if you don't also increase the ignition coil voltage you could be causing more erratic running because higher compression makes it harder to consistently ignite the fuel/air mixture unless you also increase voltage available to the spark plug. Here is a graph showing the relationship. (10 bar pressure is equal to 145psi at sea level, and 8 bar is 115psi.) A 30 psi increase in pressure requires a 15% increase in spark voltage. Fortunately you can install the Jaguar CDI to increase the spark voltage by 133%.  What about the need for a cylinder head with a squish band? In "Advances in the Design of Two-Stroke, High Speed, Compression Ignition Engines" it is written that with a squish band there is more heat loss due to swirl. [which brings more burning fuel in contact with metal.] Heat is what causes expansion of gases to push against the piston so it equates to say that heat loss, without regard to other factors, reduces power. The advantage of swirl is better mixing and flame propagation. But in a small engine there is usually already enough mixing due to its high intake/transfer turbulence. When I tested a head on my 55cc (w/o expansion chamber) that had a squish band the power was the same but top speed increased 1%. This most probably is only typical for small low power engines since larger engines need help with fuel/air mixing, and flame speed increase is helpful because of larger distances from spark plug to cylinder wall. Here are the two heads tested, both giving 170psi:  With small bore engines the problem with using a cylinder head with a squish band is that the squish band leaves too little room for the dome which means they usually cause high compression because of low head volume. Gordon Jennings wrote: "no [mass produced] 2 stroke engine in my experience had ever tolerated cranking pressures above 175psi". I don't worry about running 170psi on mine because I've replaced the crank and conrod bearings. But even so, that high a pressure will wear out the conrod bearings prematurely so I will try to dremel out even more metal from the dome area to reduce the compression. I think my tests have proved that they don't offer enough advantage and Gordon Jennings in his Two Stroke Tuners Handbook basically backs me up here: "But if you want to use a true (measured from top of exhaust port) compression ratio much over 6.5:1, on a high-output engine, combustion control beyond that afforded by a non-squish cylinder head will be necessary." (he is referring to a head w/squish band being necessary for high rpm engines with more than 150psi) The only advantage they can offer is with an expansion chamber they extend the rpm range for about 8% more top speed. That is because the exhaust temperature rises due to a longer burn which happens both from high compression and from a squish band (because 10% of the fuel mixture that was hidden from the flame under the squish band burns later). What I recommend and use is a regular head with compression of around 135psi. If you go over that or have ported the engine to rev up to at least 9,000 rpm then you should use a cylinder head with a squish band. The engine I used to test had a top rpm of around 8,000. Since very few people with these engines run higher than 130psi and/or rev higher than 9000 I think my advice concerning squish bands is accurate for the majority. When I presented this info on the motoredbikes forum the arrogant asshole Fred at CRMachine got really insulting, basically because he had no good argument to retaliate with. If you ignore my advice and want to get a high compression head then first you have to be willing to do what is necessary to make them work right. First you have to mill down your cylinder top till the piston at the top of its stroke is between .6mm and .8mm from the squish band. If you don't do that then too much air/fuel mixture will be in the squish area and not burn till too late. That causes a power loss. If you are like me though you don't want over 140psi because you don't want to have to change out the big connecting rod bearing once a year. So you will have to use your rotary tool to eat away at the aluminum dome to allow more head volume to reduce overall compression. How to measure the head/piston clearance: Buy some solder at Radio Shack. It is 1mm in diameter. Take off the cylinder head and position the piston so that when you push the bike it will rise to the top center position. Cut a piece of solder so that its length is the same distance as the piston diameter. Place it on top of the piston from front to back or from side to side. Put the head back on, tightening the nuts normally. Then quickly push the bike just enough for the piston to go past the TDC position. Pushing it too much gives too much opportunity for the solder to fall into a port and get cut off by the piston. Take the head off and measure the ends of the solder to see what the true clearance is. Keep milling down the cylinder top or head till you have the right clearance. Latest news: Now I

know an important piece of the puzzle that I didn't before all the

previous writing on this page. US Chrome says that plain chrome plating (such as

the Grubee cylinders have) has a temperature limit of 400 degrees

Celsius so a higher cylinder temperature due to advanced ignition at

high RPM in combination with high engine compression (I assume over

140psi) can be a causative factor with cylinder plating flaking. So it

is imperative that you also buy a compression tester when you modify your head or

when you buy a high compression head. Some of the high

compression heads cause 185psi!!! Yikes. guaranteed bearing failure and

cylinder plating flaking!  Here's my video on the topic of increasing engine compression: https://youtu.be/Kf9eQ7YjkL8

|