Performance CDI for China Gas/ Grubee/ Happy Times Engine48cc-80cc

Here's my video on the subject: YouTube

Copy Cat Competitors  Capacitors have different resistance to current spikes which affect how fast they can dump the accumulated voltage into the high voltage coil and how many years they will last. I am an electronics technician (since 1977) and understand this fine point, as well as others, and utilize an appropriately rated capacitor for performance and longevity although it costs more. If you want the original, and still the best, motorized bicycle CDI then buy my Performance CDI.  I made

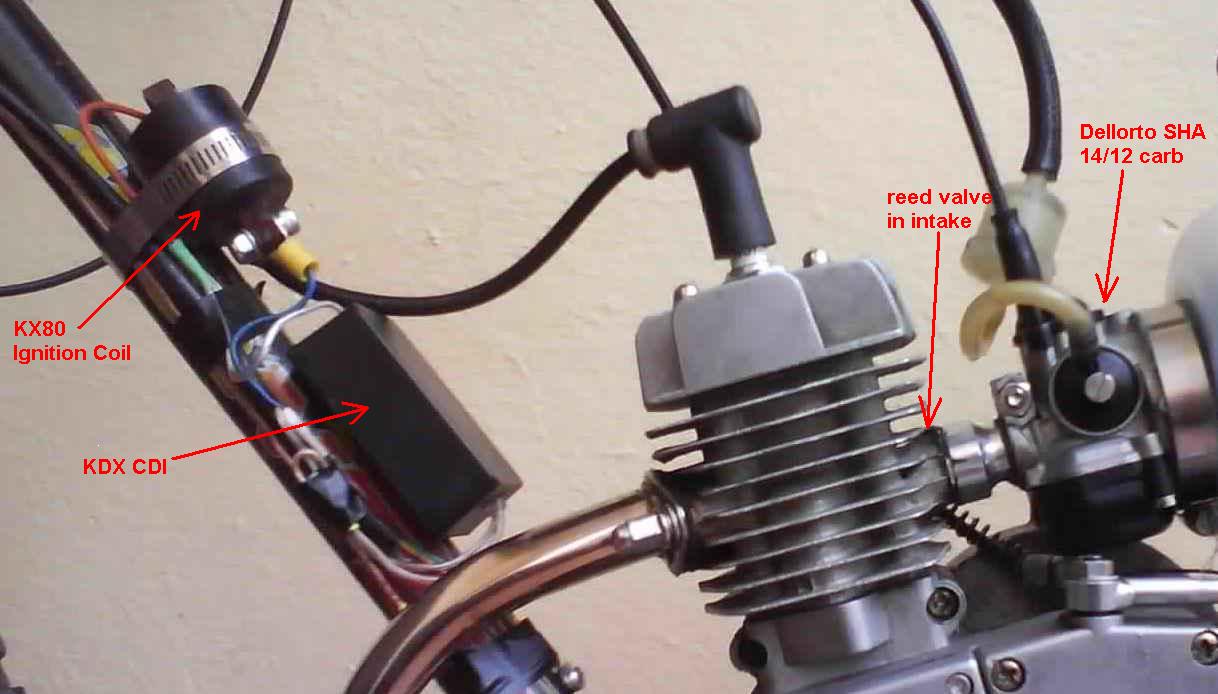

my own CDI unit by copying the design of the KDX200 CDI and modifying

it for the motorized bicycle engine. That, in

combination with a motorcycle high voltage ignition coil, improved the spark

strength and now I have an ignition system that advances and then retards

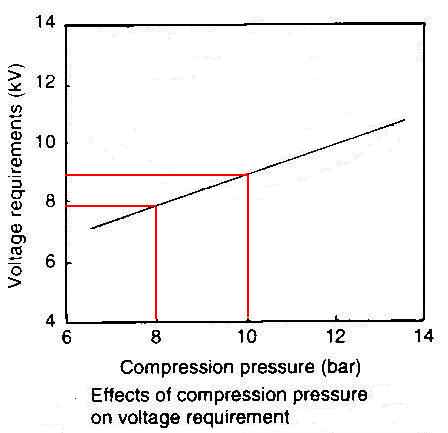

the timing as revs are increased. (see video)  Here is a digital timing curve from a PLV CDI, just as an example to show that an advance/retard curve is mostly standard for 2 strokes:  Recently I became aware of the GP version of the RS125 with a modified intake system of a rotary valve in place of a reed valve. Unusually it had a very advanced ignition curve. Why I think it's that way is it needs to be more advanced because without the extra turbulence created by the reed valve the fuel/air mixture needs more time to fully burn. So this would apply to piston port only intakes such as what the stock Grubee engine has. So for stock Grubee engines the only downfall for the stock CDI is it's a bit weak and the timing doesn't retard past its 3500 RPM peak. Anyway now my performance CDI allows a good amount of timing advance for piston port only intakes, as well as selectable amounts of retard for engines with reed valve. Max timing now is adjustable from 20.5°BTDC to 24°BTDC. (see graphs) In case you're wondering about how late in the RPM range the RSA125 starts to retard, that is normal for very high reving engines. Max RPM for a stock Grubee is only 6000. (I say "Grubee" instead of motorized bicycle engine because that is the original engine imported into USA for motorized bicycles.) Anyone after better performance usually ups the compression of the engine also. But unfortunately if you don't also increase the ignition coil voltage you could be causing more erratic running because higher compression makes it harder to consistently ignite the fuel/air mixture unless you also increase voltage available to the spark plug. Here is a graph showing the relationship. (10 bar pressure is equal to 145psi at sea level.) A 25% increase in pressure requires a 15% increase in spark voltage.  How to Determine Timing: Remove the magneto cover, take the spark plug out, stick in a screwdriver to feel piston position, rotate the magnet till you find the pistons highest position, mark with a felt tip marker one of the corners of the magnet and the stator frame where the magnet corner is. That will be your TDC (top dead center) reference point. The ignition point (seen with an automotive timing light while running) on the stator frame will be a few millimeters counter-clockwise of the TDC mark which indicates the advancement of ignition before TDC. Advancing the ignition (at the CDI) more will make the magnet mark to be even more counter-clockwise than before. Use this formula to figure out how many degrees difference there is between the new position and the reference mark. Degrees=(distance between marks x 360)/(3.14 x 36.2 magnet diameter)which equates to distance between marks x 3.17 So if the marks distance is 3mm then the degree change is 9.5 degrees. Stator (magneto) Coil: Best ones only have two wires. The 3 wire coils have less windings of the ignition coil because that space is needed for the lighting coil. EBay usually has good 2 wire coils available. Look at how fat they are, hopefully fatter at the windings than the stock coil. That indicates more windings. Best plug to use: Autolite 4092 which is non-resistor. For ported engines running higher than 7500 RPM use #4093. Champion QL78C is also good but it has 1.9K resistance. Less resistance means hotter spark. Motorcycles need resistance in the plug or the plug cap because they have a higher voltage since they use beefy stator coils, not the wimpy ones these engines have. I buy from Advance Auto. From "Devices to improve the performance of a conventional

two-stroke spark ignition engine" |