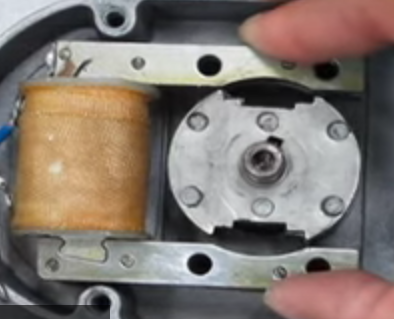

Running Essentials:1) gasoline/air mixture (mixed not too lean or too rich)2) compression (both in crankcase and combustion chamber) 3) spark (of sufficient strength and at the right time each cycle) Incorrect fuel mixture ratio: A) Vacuum in the gas tank due to lack of functioning vent hole will let the engine run for a while and then die. Taking the cap off to see if there is fuel there relieves the vacuum. The spark plug will not be wet when removed and inspected. Drill a small hole in the bottom lip of the cap. B) Trash all around the fuel filter in the tank can prevent fuel flow. Remove the petcock to inspect and clean it. C) Trash inside the float bowl can get into the main jet and prevent fuel transfer into the throat of the carb. Use bare wire from a twist tie to push into the main jet to break free any obstructions. D) A carb float valve not sealing will allow the fuel to fill up too high in the float bowl to make it run rich. The stock NT carb lacks a spring loaded float needle and tends to not seal good, especially on bumpy roads. This allows too much gas in which can overflow and can choke out the engine. Testing: Take the float bowl off and turn the gas petcock on and move the float up and down to see if the fuel flow stops when the float is up. If bad then clean the valve and if it still continues then replace the carb. If good then adjust the float tab so that the on/off point is 21mm from the carb body. (read more). E) A restrictive air filter will cause it to run too rich. Remove the air filter and seat it on your face around your mouth and blow hard. If you can feel its resistance to air flow then it is too restrictive. I made my own by gluing (with silicone sealant) together foam sections cut from a lawn mower filter. F) An air leak at the beginning or end of the intake manifold can cause it to run too lean. With the clutch lever held in does it take a while for the idle to settle down to its normal putt-putt after twisting the throttle and then letting it go? That would indicate a leak at the seals or at the intake manifold (usually where the carb connects to it). Use gasoline resistant glue (not silicone sealant) at the intake manifold if necessary. COMPRESSION PROBLEMS Clutch Slipping It’s possible the clutch is slipping too much to let the engine turn over. With the left cover off just look to see if the magneto is rotating when you push the bike. If not then adjust the clutch if there is some slack in the clutch cable (which is necessary) Air Leak at the crank seals: A leak here will lose crankcase compression which reduces power, sometimes to the point of not even being able to start the engine. The right side of the crankshaft has a lip that the seal can catch on, so even a new engine can have that seal leaking due to not seating correctly. I like to use a file to round that lip off. Testing: take the magneto and stator coil off. take the spark plug off. spray the seal area with soapy water (using dishwashing soap). turn the engine over and watch for bubbles. then on the right side take the primary gear off and do the same. bubbles indicate a seal leak. Air leak at the head/cylinder: Most of these heads come slightly warped from the factory and the aluminum gasket is meant to be thrown away the first time it is removed (because it can only conform to irregularities once). A loss of compression here greatly reduces engine power or the ability to start. Plane the head flat by use of sandpaper on thick glass. Buy gasket material from the auto parts store and make your own gasket. With patience and effort you can also keep grinding down the head to remove up to 2mm so that the compression will increase to around 135psi (higher is not recommended due to weak cylinder plating). Stock is around 90psi if the head is sealing good. But don’t take off much more metal than what is needed to make it flat unless you buy a Jaguar CDI which has the retarded ignition timing needed for higher compression. (read more)  IGNITION SYSTEM PROBLEMS Unless you are checking for spark with a timing light while it's running (because the light won't turn on unless there is a surge of current going thru the wire to the spark plug which indicates a spark event) you cannot be sure the spark is happening. It can spark outside the engine with the plug removed but not inside the engine. Why? The voltage needed to make a spark increases with pressure increase. The current return path can be intermittent if you haven't removed the shellac from where the 4 screws contact the stator coil frame. (see https://www.youtube.com/watch?v=Nd2G9FB1nJk) The stator coil can have an intermittent short (voltage dependent). The CDI can be intermittently faulty. The magnet can be installed backwards which will make the ignition timing so far off that the engine won’t start. The spark plug may be damaged or too dirty and needing replacement. Make sure the plug gap does not exceed .025" because more gap requires more voltage to create a spark. If you have a kill switch then disconnect the wire going to it to see if it is the problem. Make sure the wires going from the stator coil to the CDI have good connections. Two rusty wires twisted together does not make for good conduction. Testing the spark ignition: Remove the spark plug and connect the spark plug cap from the high voltage coil to it. Manually hold the spark plug with cloth onto the cylinder head and make sure the side electrode is sideways so you can see the spark gap clearly. Push the bike to see if any spark is generated. It is hard to see in full daylight so its best to do at night or inside. If no spark happens then there is a problem. If you have spark but the engine won't start then one of these problems exist: 1. Compression is being lost due to loose head nuts or non-parallel head/cylinder mating surfaces (that you can fix with sandpaper and glass). 2. There is an input air leak due to loose intake manifold connections or poor sealing where the carburetor connects to the intake manifold. 3. Crankcase compression is being lost due to bad crankshaft seals. 4. Something is really wrong with the carburetor such as a jet being clogged. 5. The ignition system is just strong enough to create a spark with the spark plug outside the engine but not inside the engine. 6. Someone put the magneto on backwards so that the spark is happening at the wrong time. This photo shows the magneto correctly installed with the piston at top dead center:  Test the Stator Coil: Use an AC voltmeter to test for 25-50 volts coming out of the stator coil as you push the bike with the spark plug removed. I prefer using an analog voltmeter such as this one. If the voltage is there then the stator coil is OK although I would still remove the stator coils mounting screw that fastens the ground wire to the metal ground so that you can clean it for good conduction. If the voltage is too low then either the stator coil has a short circuit in it or the magnet is weak and needs to be replaced. Usually the coil is the problem. Test the CDI: You can test for total circuit performance (without determining the peak output voltage which requires a special test circuit or a meter that can read peak voltage) by just holding the bare CDI output wires while pushing the bike. Someone may have to help you with that. Start out very slow and gradually push faster till you feel a minor shock. I prefer this basic method because the output voltage lasts for only a few thousandths of a second which most meters can't register. If you are getting shocked then suspect the high voltage coil or the spark plug cap or the spark plug as bad. |