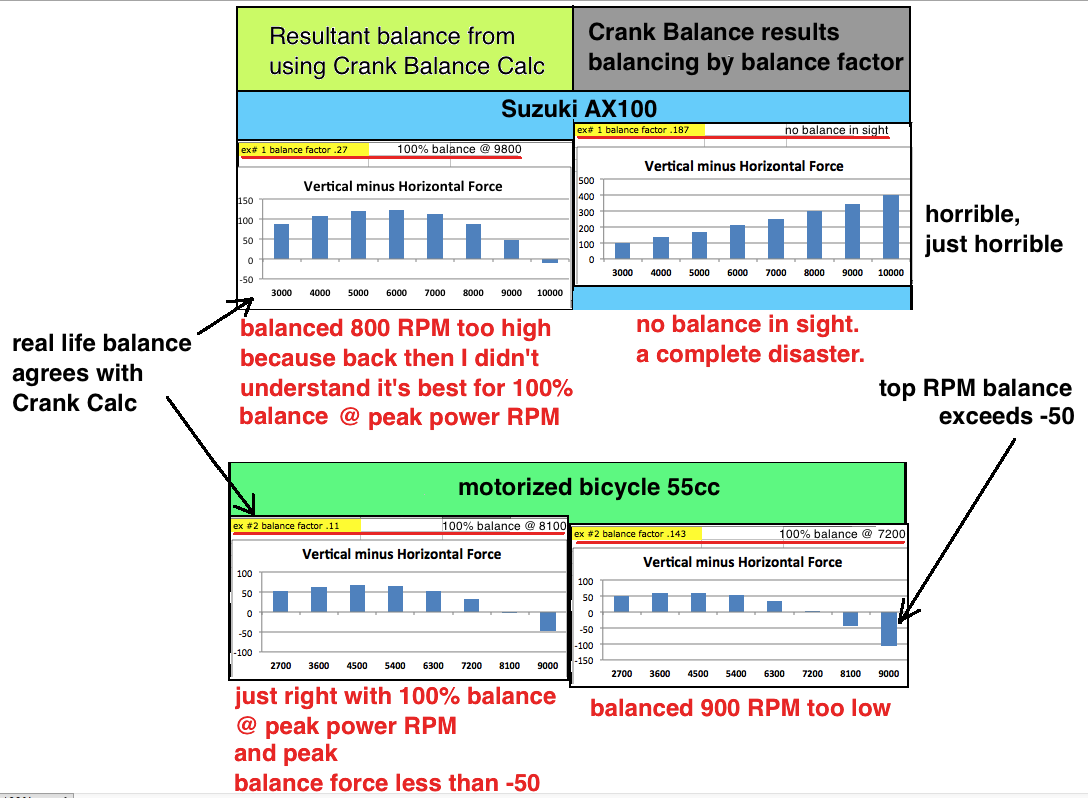

Here's some good quotes from http://victorylibrary.com/mopar/crank-bal-c.htm that tells the main reasons I have never had any interest in trying to balance a crank using a balance factor. - - - - - - - - - - The "balance factor" is at best a compromise, and partially suppresses vibration at some RPM and power/vacuum levels. Classifying the connecting rod's upper and lower halves as "reciprocating" or "rotating" is not completely accurate. The rod's pin eye does reciprocate, but the rod's absolute upper end (including the material closing the top of the eye), and the rod beam between the pin eye and the crankshaft's rod journal follow different and more complex paths. The rod's big end does rotate, but only the imaginary line marking the contact with the crankshaft's rod journal is "pure" rotation, the rod's big end actually oscillates as well. Mathematical-based formula using only conventional factors will never predict accurately how well a given engine will run, even at a given RPM, because the dynamic forces aren't limited to reciprocating vs. rotating weight. The forces acting on the rod + crank-pin (mass inertia) are not only the reciprocating weight (as listed above), but also the forces present in the cylinder and combustion chamber above the piston. No formula is "correct", some just come closer than others, by the "empirical" method - they've been tried + adjusted by experiment. The bottom line is that the physics and mathematics involved in how the engine operates are far too complex to make a formula-based balance factor any more than a reasonable compromise. - - - - - - - - - - - - - "Balance Factor" is an incomplete system which is why I made my spreadsheet. It is the only program to date that painstakingly figures out the con rods contribution to the reciprocating and rotational forces, every 15 degrees. It doesn't cheat and use a percentage of the con rod weight for each force. That method is inaccurate. - - - - - - - - - - Some people still think that the balance factor is something other than a way of recording what you found to work by trial and error. All I have to say to them is let's put your method to the test. Here's two sets of data that I posted on a forum for this pro-balance-factor guy (Street Ryderz on motoredbikes forum) to tell me what balance factors he thinks will work: case #1: piston assembly 122 grams wrist pin 24 gm con rod 133 gm weight at the small end of con rod that statically balances the crank: 52 gm top RPM 10,200 test case #2 piston assembly 66 grams wrist pin 10 gm con rod 85 gm weight at the small end of con rod that statically balances the crank: 23 gm top RPM 8,400 He responded and gave me a balance factor of .187 for the first one and .143 for the second one. Look at the graphic below which shows these two test cases on the left and what their balance would look like on the right if they were balanced using the balance factor. I can tell you from riding my bikes that what the graph says and what I experience are nearly exactly the same. The first AX100 graph has 100% balance (where it crosses the zero line) a bit higher than I prefer now but that was back when I had the program set to balance it that way. At top RPM anything within 50 of the zero line is not felt hardly at all on a small engine. Any way the results here speak for themselves. Using balance factor is as hit and miss as throwing a dart trying to hit the bullseye. It's just no good.

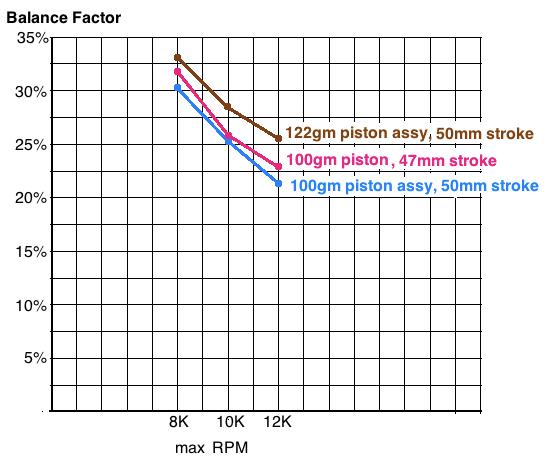

The graph below was made by myself trying to find the fators that a set balance factor is thrown off by, and they are max RPM, stroke, and piston assembly weight. So with 3 variables interacting do you think anybody can accurately tell you what balance factor to use? No way! It's a wild guessing game. Stroke throws it off because with a longer stroke but same RPM the upward force at TDC is greater due to greater piston speed.

HOME |