|

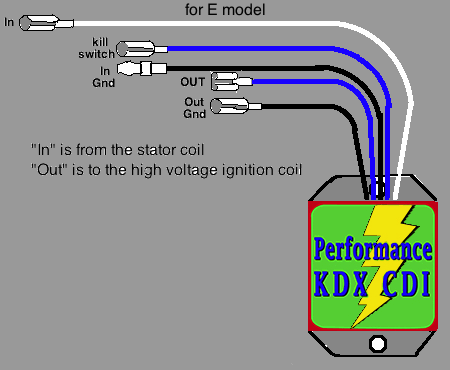

Switch A can be positioned for a Kawasaki original stator or an aftermarket stator (which advances the timing throughout the RPM range). Switch B can be positioned for standard timing or for more retarded (delayed) timing for better power at high RPM. HOW TO ACCESS THE SWITCH: Just remove the boxes screws with a small Phillips screwdriver. Once the box lid is removed you can see the switches. You can just use your fingernail or a small screwdriver to manipulate the switches. Once you settle on switch settings then use silicone sealant to seal the lid so the box is waterproof.  But first just plug the CDI into

the CDI connectors which

should be the same.   DETERMINING BEST SWITCH

1 SETTING: First set the switch to setting C to match a standard stator coil, or to A or B to match an aftermarket coil. Ride the bike to test its mid range power, but first make sure the idle wasn't thrown off (usually it isn't). If the engine tends to kickback when kickstarting then the stator plate needs to be turned CCW. And if idle is too weak then turn the stator coil plate CW for more timing advance. Once you get the idle set right (hopefully the idle jet isn't partially clogged and throwing everything off) throw the switch to the another position and go riding. Keep doing this till you find the best position. If you can't really tell any difference then leave it at C to match a standard stator coil, or B to match an aftermarket coil.  DETERMINING BEST SWITCH 2 SETTING: With all the three switched to the low position the high RPM timing is standard, the same as stock. The more of these switches that are set in the high position, the more retarded the high RPM timing will be. I think most KDX's will like the 2nd switch high, or the 1st and 2nd switch high. The retarding effect of the 1st switch is half that of what the 2nd and 3rd switches can do. Its a nice option for fine tuning. The drawing on the right shows the 6 different tuning settings available and the switch lever positions for each.  TESTING: The best way to test is by having two markers along a road and then time how long it takes to reach the second one. Do this wth a stopwatch. Pass the 1st marker at the same speed each time. This is also the best method for selecting the needle position and the size of the main jet, which you can test for after you select the best switch positions. People have been under a mass delusion that they can select a main jet by the color of their spark plug and/or the width of the carbon band at the bottom of the plugs ceramic. Both of those methods are disproved on this page. RE-ADJUSTING Adjusting switch 2 at settings D to F also affects the mid RPM timing at 4000, so after setting switch 1, and then switch 2 (D to F), you need to try different settings again for switch 1 and 2 if you want the absolute best settings. The graph below shows the blue timing curve graph which is closest to the standard green graph, and the red graph which is the most retarded.  PS - these pictures were taken before I sealed it up with silicone sealant (all except the switches). After you select the best switch positions you can put silicone sealant over the switches lightly to make them waterproof. I think it's overkill though unless you cross rivers and occassionally drown it. |