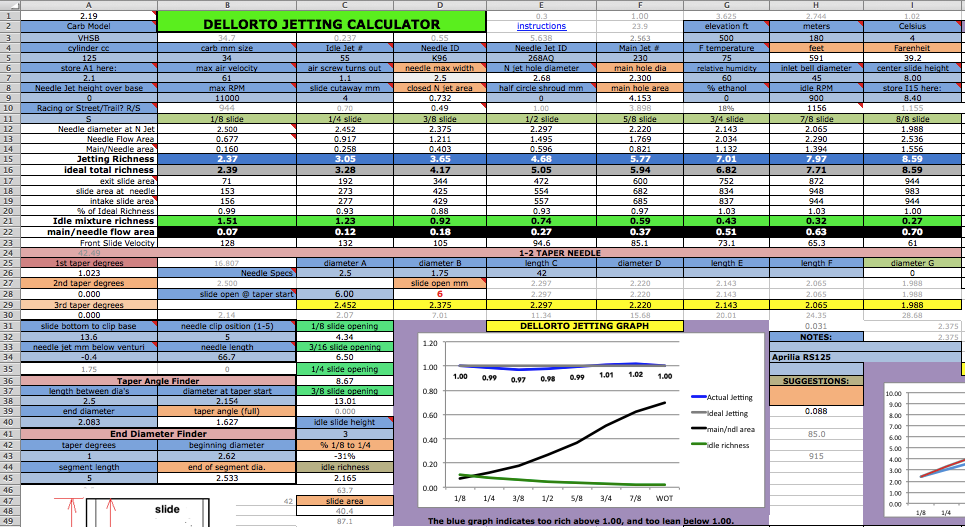

Jetting DellOrto Carburetors Below is a screenshot of my spreadsheet for DellOrto carbs. Near the bottom of this page are the links to the needle and needle jet info that you will need to know such as the inner diameter of the needle jet of your carb. Here's how to use the spreadsheet: Enter data into all the light blue cells of the spreadsheet and the program will graph the jetting. If you hover the mouse pointer over a cell with a red corner then a message will pop up telling you about that cell.  Here's the sequence to follow: 1) First make sure your real life idle jet size is correct. Some Dellorto's have an idle mixture limiter screw adjuster instead of an air screw adjuster. The A paragraph is for carbs with an air screw, and B is for mixture limiters: A) Turn in the slide stop screw till you have a slightly fast idle. Then slowly turn the air screw till you find where it idles the fastest, then readjust the slide stop for the same fast idle as before if it has changed. Then slowly turn clockwise the air screw till the idle speed starts to drop off due to starting to be too rich (but which is good for starting w/o the choke in warm weather). This should result to be within 1 to 2 turns out. (Forget the untrue 1.5 turn "rule" which never came from the carb manufacturers.) If it is less than 1 turn then you need a bigger idle jet. If it is more than 2 turns then you need a smaller idle jet. Install the correct idle jet if necessary and repeat procedure, adjusting the idle air screw. Then turn the slide stop screw till you have a normal idle speed. The right idle jet is what gives these two things: 1) the most consistent idling when the engine is hot, 2) the best off-idle power as you open the throttle slowly. Later you can change the slide stop position, idle jet, and air screw setting to your own preference, the best example being that racers let the slide low enough for engine braking that is too low to allow the engine to idle. Normally if you have to make the idle mixture too rich for smooth idling in order to help compensate for weak throttle response as you crack the throttle open then you either have the needle clip in too high a position (lowered needle), the needle is too fat, or the needle jet (the brass hole the needle slides into) is too narrow. B) Turn in the slide stop screw till you have a slightly fast idle. Then slowly turn the mixture screw till you find where it idles the fastest, then readjust the slide stop for the same fast idle as before if it has changed. Then slowly turn counter-clockwise the mixture screw till the idle speed starts to drop off due to starting to be too rich (but which is good for starting w/o the choke in warm weather). ******* Install the correct idle jet if necessary and repeat procedure, adjusting the idle mixture screw. Then turn the slide stop screw till you have a normal idle speed. The right idle jet is what gives these two things: 1) the most consistent idling when the engine is hot, 2) the best off-idle power as you open the throttle slowly. Later you can change the slide stop position, idle jet, and mixture screw setting to your own preference, the best example being that racers let the slide low enough for engine braking that is too low to allow the engine to idle. Normally if you have to make the idle mixture too rich for smooth idling in order to help compensate for weak throttle response as you crack the throttle open then you either have the needle clip in too high a position (lowered needle), the needle is too fat, or the needle jet (the brass hole the needle slides into) is too narrow. 2) Make sure your main jet is correct. The simplest method is to try a few jets and pick the richest one that allows clean WOT running. Click here to find out the best way to size the main jet. For small carbs you may need to cut down the needle shroud if one main jet size is too rich and the next smaller size is too lean. In that case put in the rich jet and then lower the shroud .5mm (.02") at a time till the jetting is right.

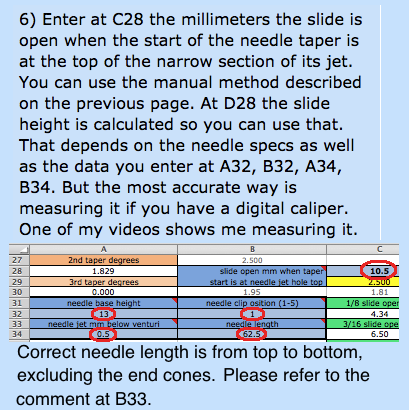

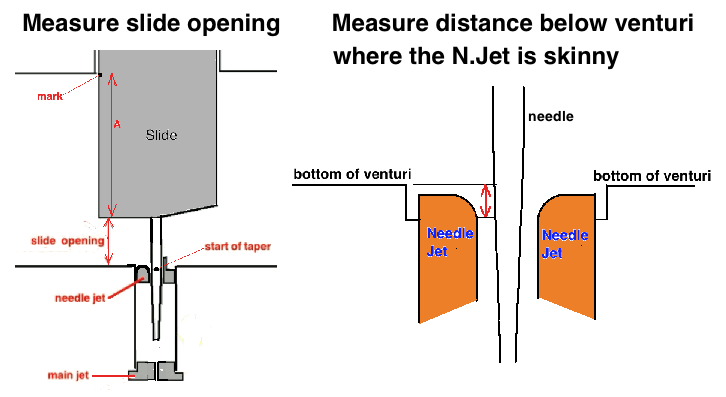

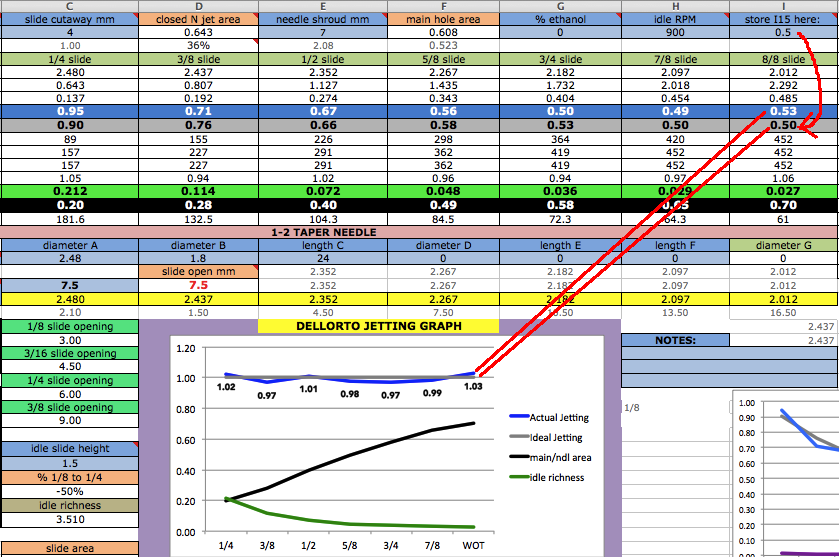

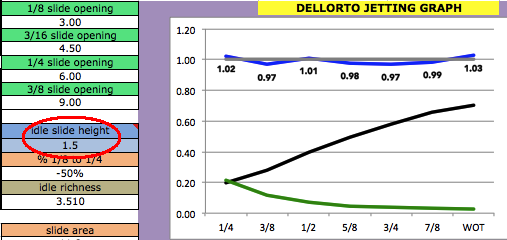

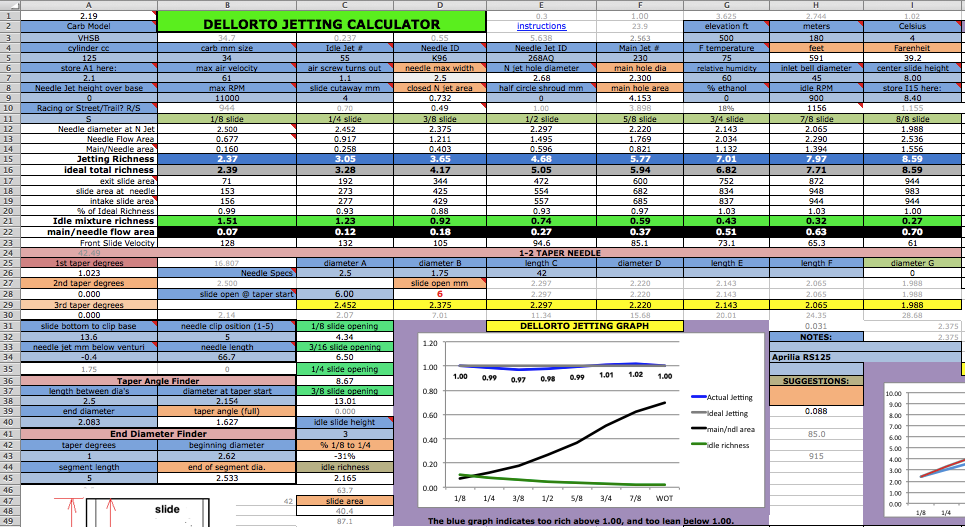

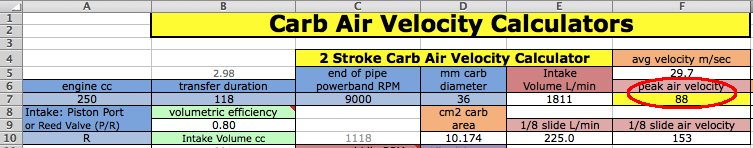

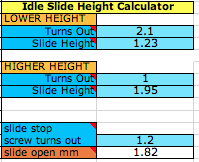

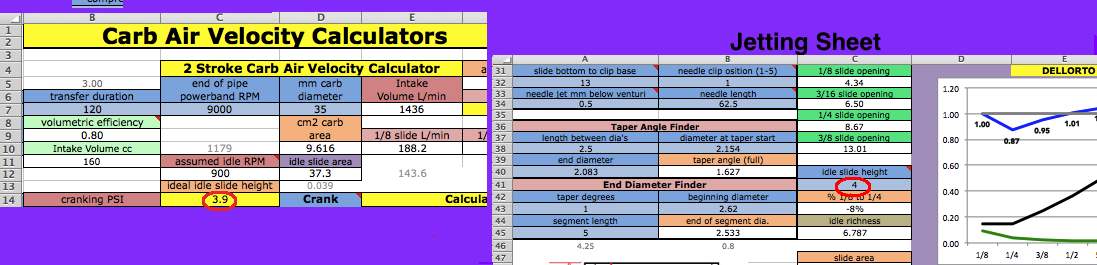

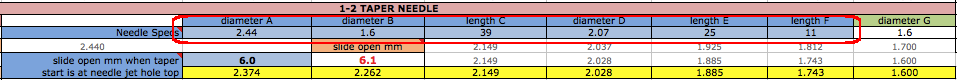

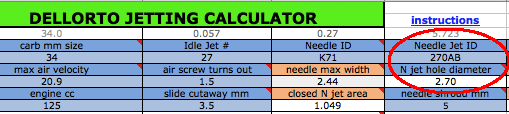

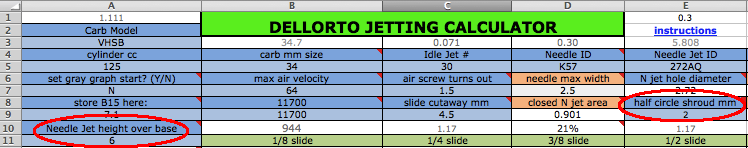

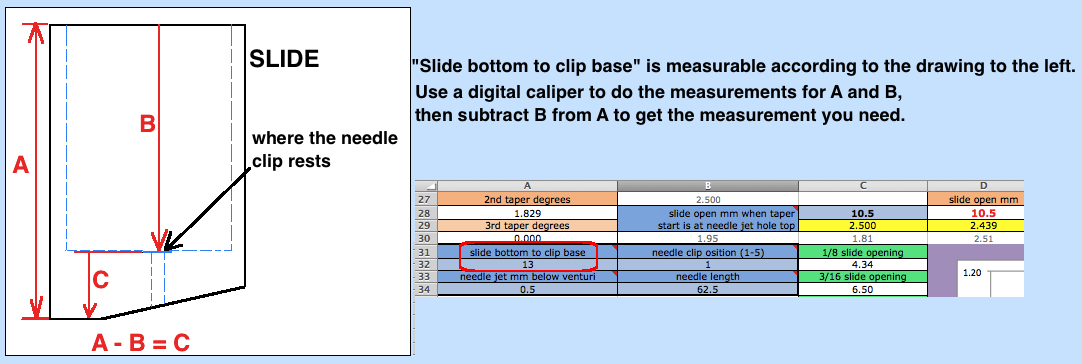

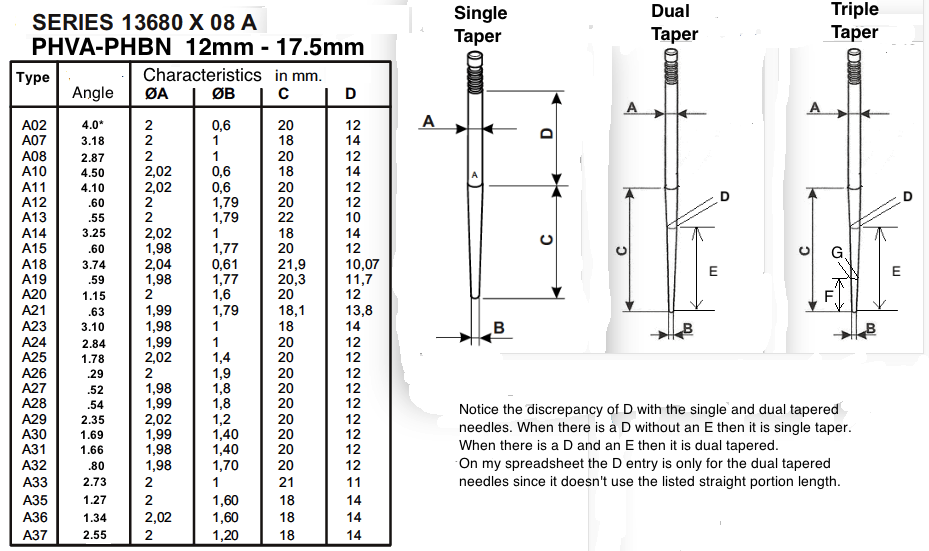

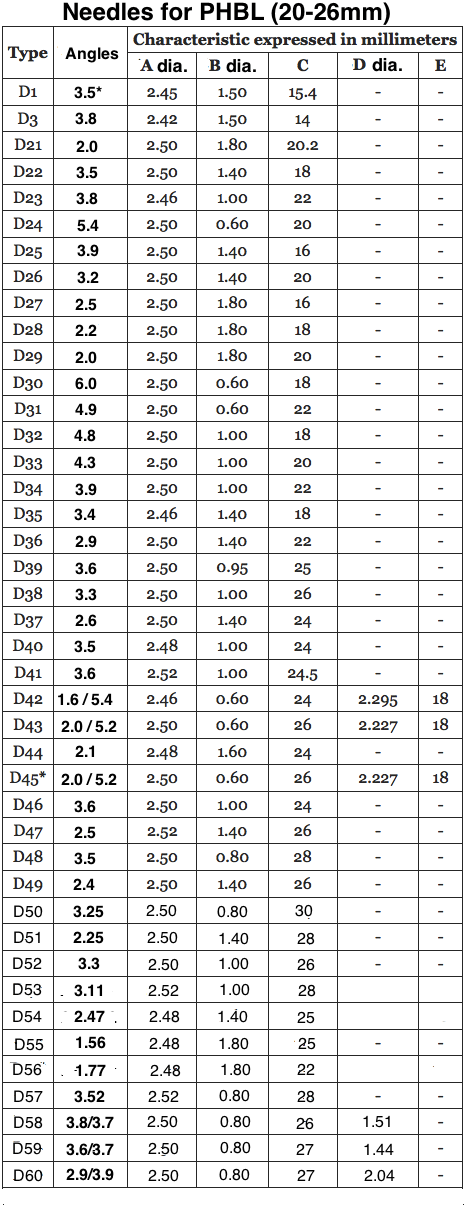

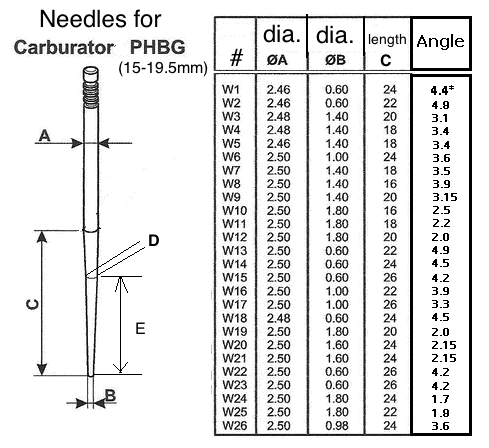

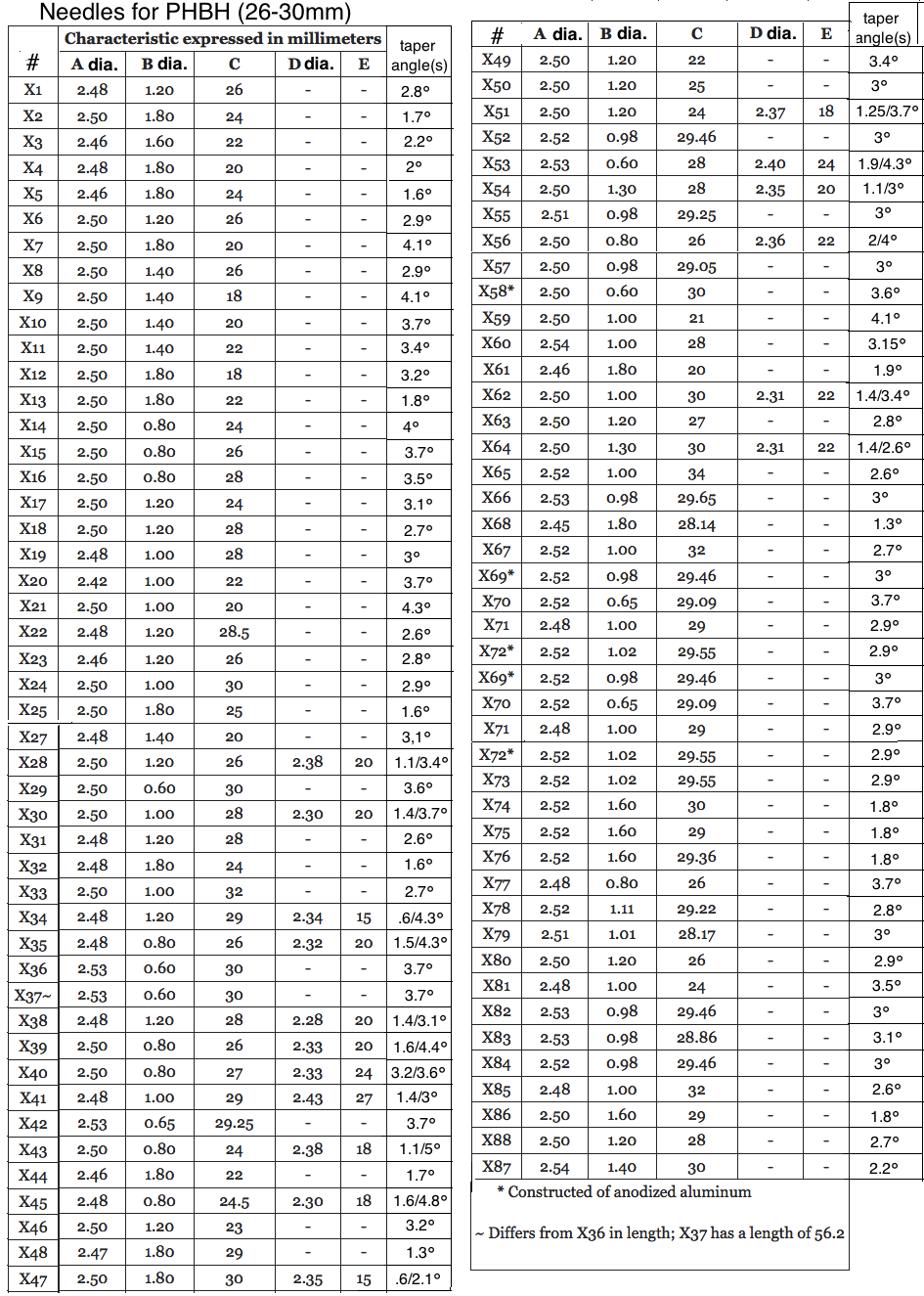

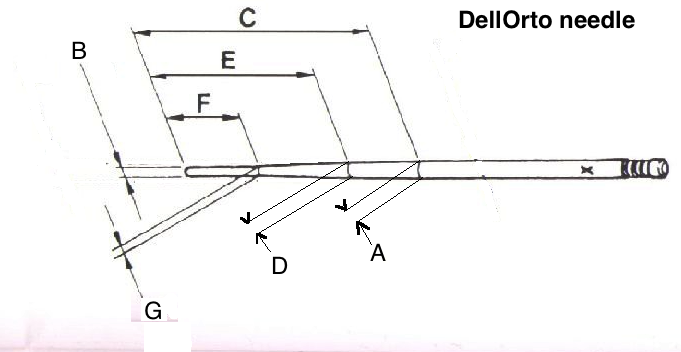

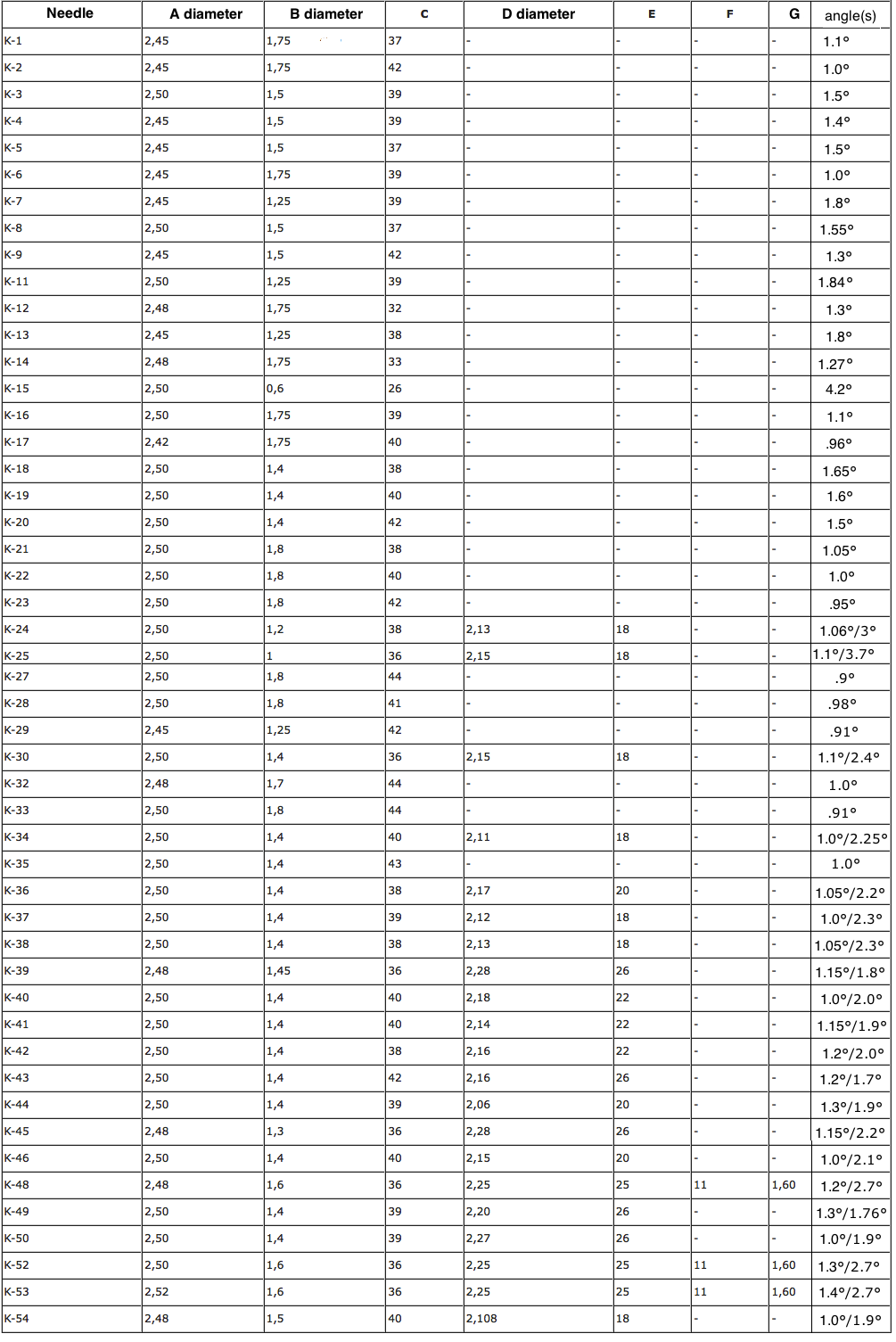

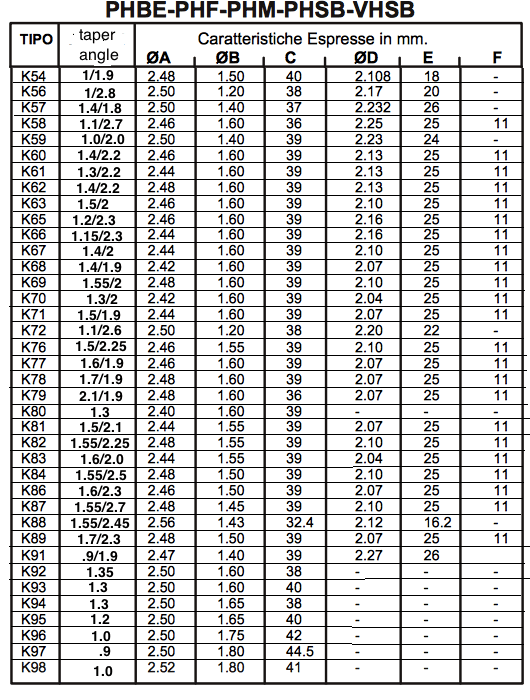

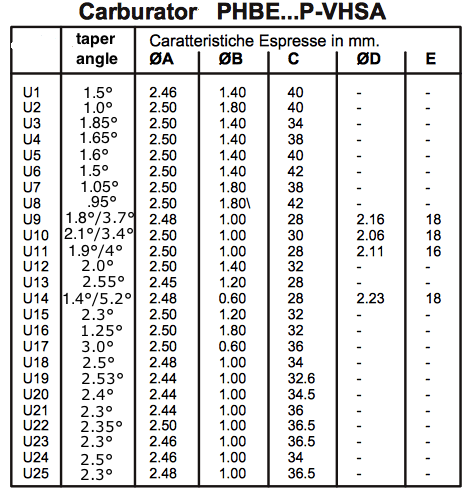

3) Go to the last sheet (click on the velocity tab at the bottom left of the screen) to find out the maximum air velocity to enter at B7 of the jetting sheet. If you aren't sure of the transfers duration then enter 125-130 for race engines or 115-120 for street/trail engines.  You'll need to set the slide stop screw for an even engine idle and then take the carb off and measure the idle slide height for C41 of the Dellorto sheet. That is hard to do and so I made a mini calculator on the 1st Mikuni sheet, N15 to O27, that allows you to use two allen wrenches, one of a size smaller than the slide open mm, and one larger than that to calculate what the slide opening is according to the turns out of the slide stop screw.   4) At C26 to H26 enter the data for your needle and the program calculates the needle diameter for every 1/8th distance of the carb bore.  5) The needle jet (which Dellorto calls an atomizer) hole diameter is indicated in its ID. Take the first 3 numbers and put a decimal point after the first one to get its diameter in millimeters. If you aren't sure of its ID then you may have to measure the hole size.  Enter the height of the half circle needle shroud over the top of needle jet at E9. (It's called an atomizer bush and is pictured below.) If there is no half circle needle shroud then enter 0. Enter the height of the needle jet over the venturi base at A11.

If your carb has a mixture limiter screw instead of an air limiter screw then put 1.5 at C7 and if the beginning of the graph is off from reality then change the # at A7 to make it represent what you are feeling when reving and riding it.

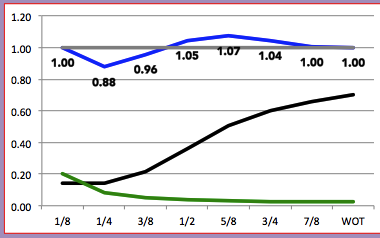

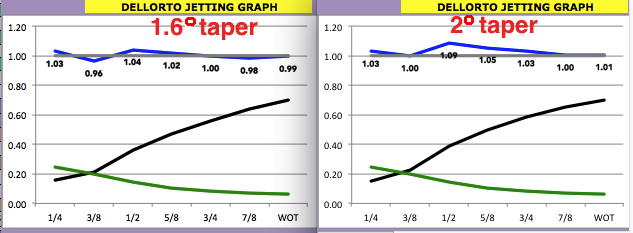

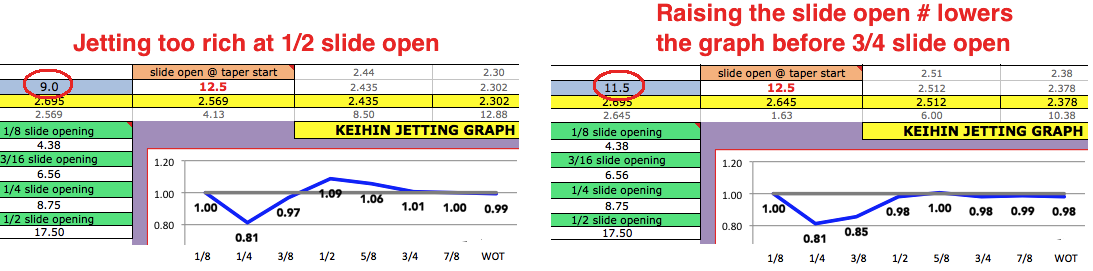

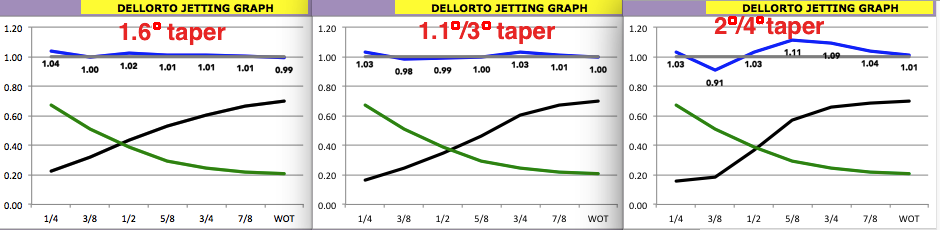

Multi-tapered needles can be good like this 1.1*/3* one, or they can be terrible like this 2*/4* one. It's just such a huge advantage to test them virtually using this software first.

11) Re-record this spreadsheet with all of your data in it. For example, if saving data for a YZ250 then save it as JettingCalcYZ250.xlsm  DellOrto DellOrto calls their needle jet an 'atomizer' and you need to make sure your DellOrto carb has a 2 stroke atomizer because the 4 stroke atomizers have more air holes in their sides which changes the flow which makes my calculator unsuitable for selecting a good needle. (This holds true for all carburetors.) 2 stroke atomizers are labeled AQ, AU, AV, AS, AB, AF, AR. The hole diameter is known by dividing the atomizer # by 100. This site lists the atomizers and their carburetors. This site also sells atomizers without listing any spec but their hole diameter. Treatland sells genuine Dellorto jets. Here's what DellOrto carbs are often equiped with:   Following is the Dell'Orto data on needles for carbs PHBN, PHBG, PHBL, PHBH, PHBE.      The commas represent decimal points in tthe chart below. It looks like some needles have 3 tapers but actually the last one is just a straight section.    If you have any questions then just email me at a57ngel@yahoo.com |