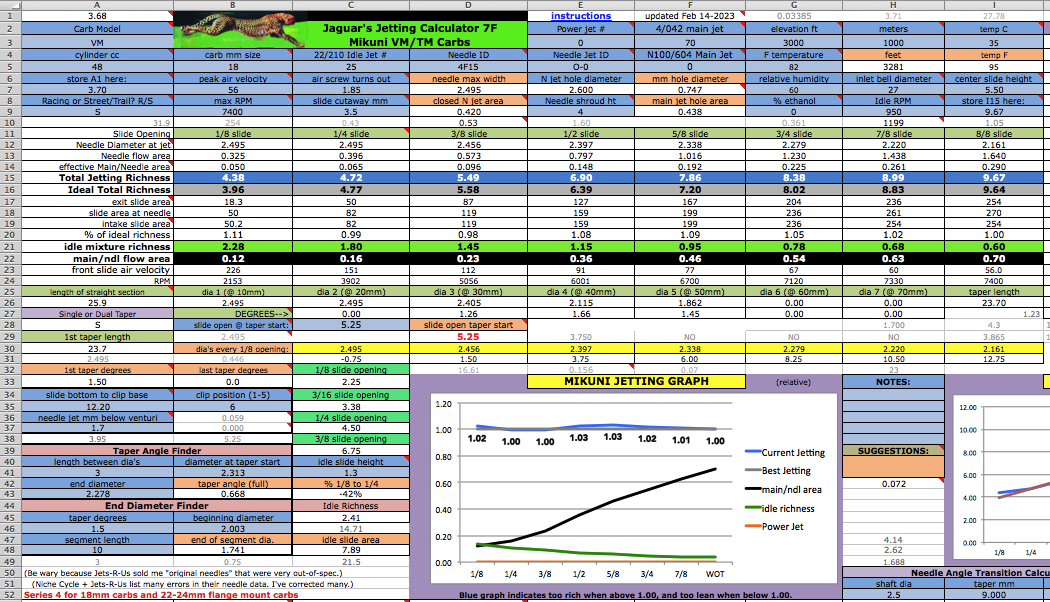

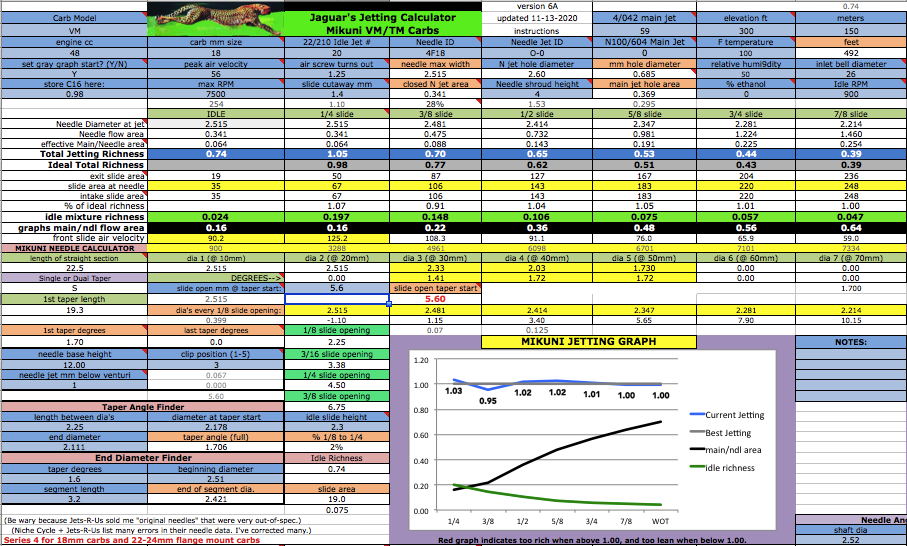

Jetting Mikuni VM/TM carburetors Click here for my page verifying the Jetting Calculator for Mikuni VM/TM carbs. Below is a screenshot of my spreadsheets page for Mikuni VM and TM carbs. Here's how to use it: Enter all the data in the light blue data boxes and the program will graph the jetting. If you hover the mouse pointer over a cell with a red corner then a message will pop up telling you about that cell. 3/4 down this page are the links to the needle and needle jet info that you will need to know, such as the needle jet ID of your carb. Starting at row 53 on the spreadsheet are all the VM and TM needles and their data.  Here's the sequence to follow: 1) First make sure your real life idle jet size is correct. Turn in the slide stop screw till you have a slightly fast idle. Then slowly turn the air screw till you find where it idles the fastest, then readjust the slide stop for the same fast idle as before if it has changed. Then slowly turn clockwise the air screw till the idle speed starts to drop off due to starting to be too rich (but which is good for starting w/o the choke in warm weather). This should result to be within 1 to 2 turns out. (Forget the untrue 1.5 turn "rule" which never came from the carb manufacturers.) If it is less than 1 turn then you need a bigger idle jet. If it is more than 2 turns then you need a smaller idle jet. Install the correct idle jet if necessary and repeat procedure, adjusting the idle air screw. Then turn the slide stop screw till you have a normal idle speed. The right idle jet is what gives these two things: 1) the most consistent idling when the engine is hot, 2) the best off-idle power as you open the throttle slowly. Later you can change the slide stop position, idle jet, and air screw setting to your own preference, the best example being that racers let the slide low enough for engine braking that is too low to allow the engine to idle. Normally if you have to make the idle mixture too rich for smooth idling in order to help compensate for weak throttle response as you crack the throttle open then you either have the needle clip in too high a position (lowered needle), the needle is too fat, or the needle jet (the brass hole the needle slides into) is too narrow. 2) Make sure your main jet is correct. The simplest method is to try a few jets and pick the richest one that allows clean WOT running. Click here to read about getting the main jet right. For small carbs you may need to cut down the needle shroud if one main jet size is too rich and the next smaller size is too lean. In that case put in the rich jet and then lower the shroud .5mm (.02") at a time till the jetting is right.

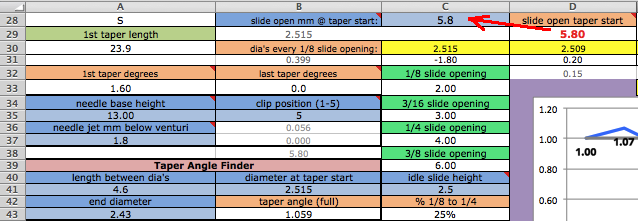

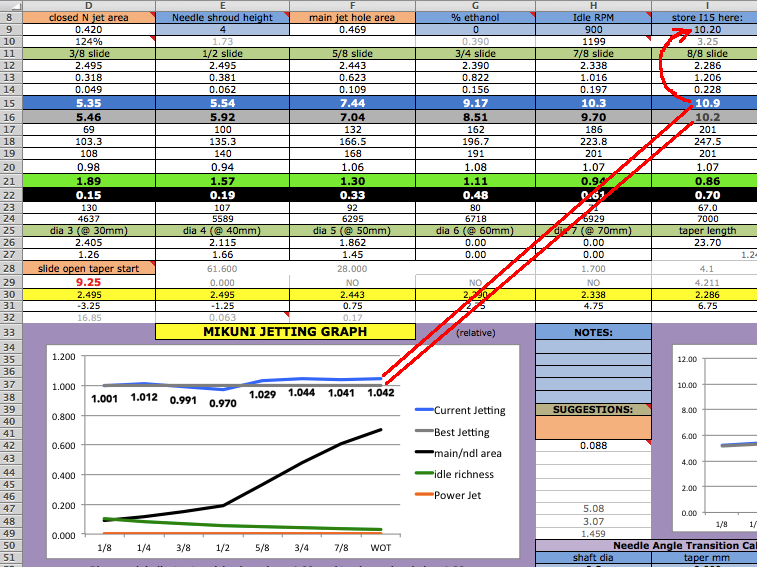

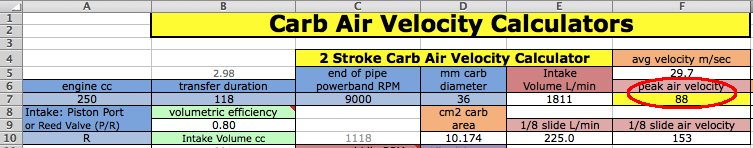

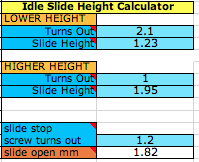

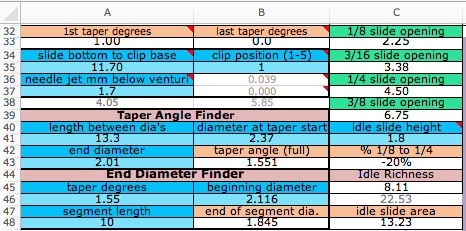

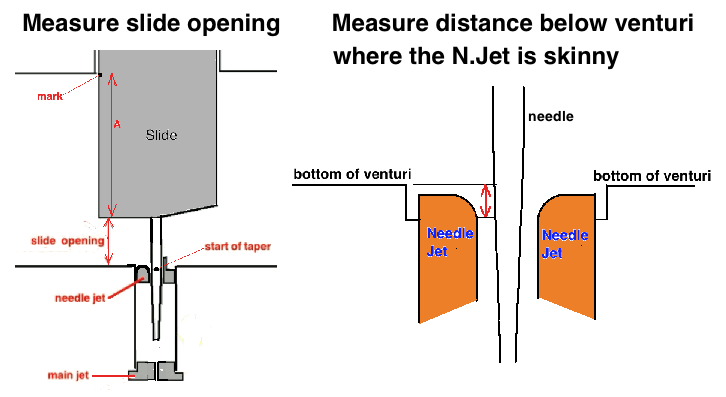

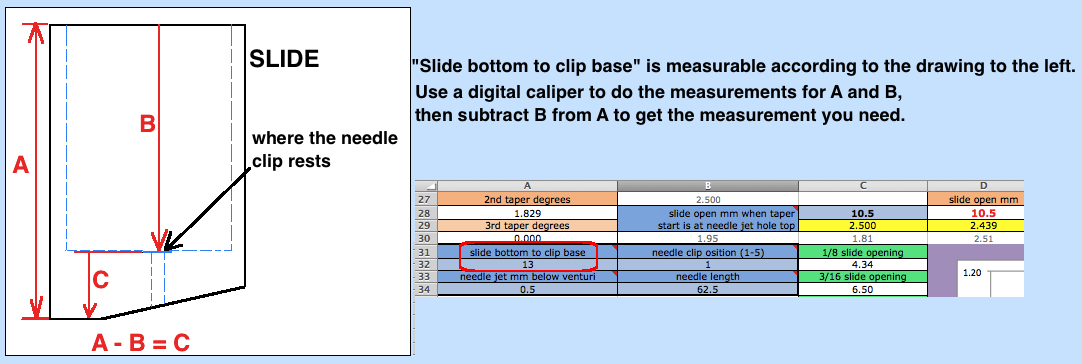

3) Go to the last sheet (click on the velocity tab at the bottom left of the screen) to find out the maximum air velocity to enter at B7 at the sheet you are using (depending on carb). If you aren't sure of the transfers duration then enter 125-130 for race engines or 115-120 for street/trail engines.  4) You'll need to set the slide stop screw for an even engine idle and then take the carb off and measure the idle slide height for C41 of the jetting sheet. That is hard to do and so I made a mini calculator on this sheet, N15 to O27, that allows you to use two allen wrenches, one of a size smaller than the slide open mm, and one larger than that to calculate what the slide opening is according to the turns out of the slide stop screw.   5) Enter either the 4/042 main jet # (@ F3) or the N100.64 main jet # (@ F5), depending on which your carb has. VM carbs come with 4/042 main jets but some TM's have the N100/604 jet. These series of TM carbs come with N100/604 main jets: TM33-8012, TM36-68, TM40-6. Put 0 in the cell not used because the graph will crash if both jet #'s are there. 6) At D5 you enter the needle ID (code) so the program can find the needle in the listing farther down the same sheet and use its data for the calculations. The needle ID is imprinted near the top of each needle. Data for custom needles or ones not listed on this sheet can be entered at rows 178 to 184. Give any custom needle a unique ID.

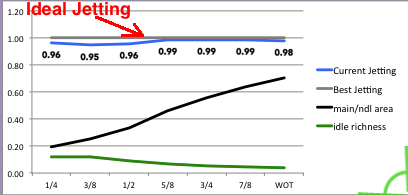

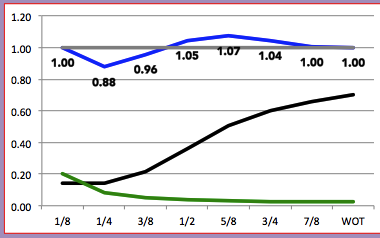

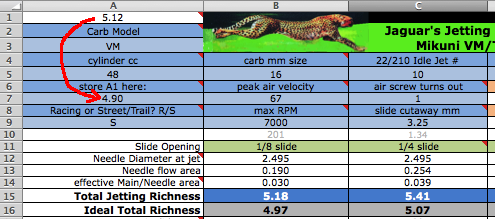

If the beginning graph is off from reality (blue too high or too low) then change the # at A7 to make it represent what you are feeling when reving and riding it. This will compensate for any bad measurements you've made or the idle circuit design varying from what is expected by the formulas which were set to match my VM18.

12) Re-record this spreadsheet with all of your data in it. For example, if saving data for a YZ250 then save it as JettingCalcYZ250.xlsx You can email this to me with any questions you may have at 19jaguar75@gmail.com

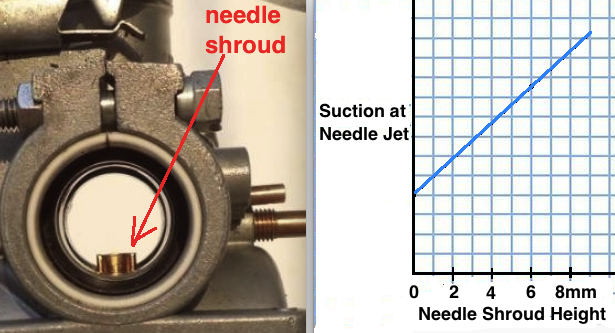

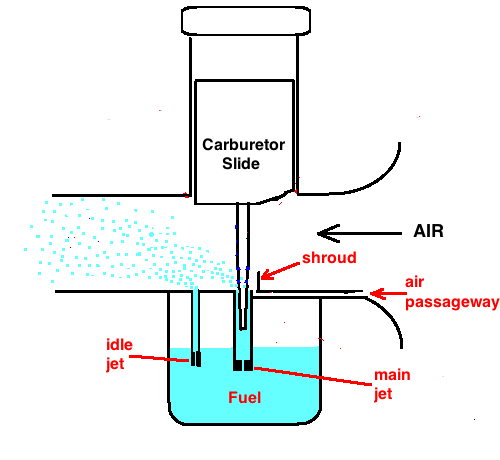

These graphics will show you what I mean by "needle jet shroud" which on the spreadsheet you have to enter its height at E9. It causes more vaccuum at the needle jet which pulls more fuel up. You can lower the shroud instead of finding a leaner needle with less taper angle. Changing its height helps with jetting a small VM because the available jets don't have sizes close enough together for the small sizes. Usually the VM18/22/24 have a needle shroud. All the TMS/TMX's have one. It is basically a little more than a half circle extending up from the needle jet on the air filter side.

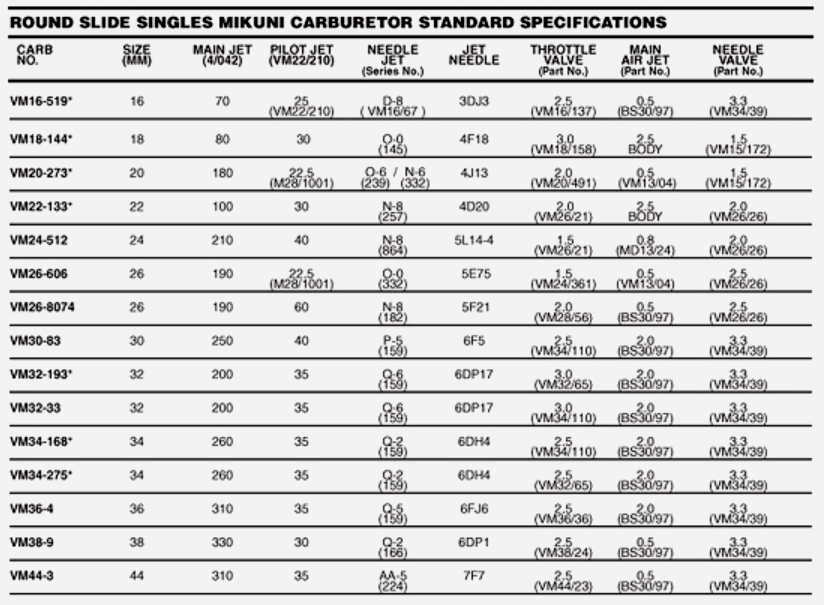

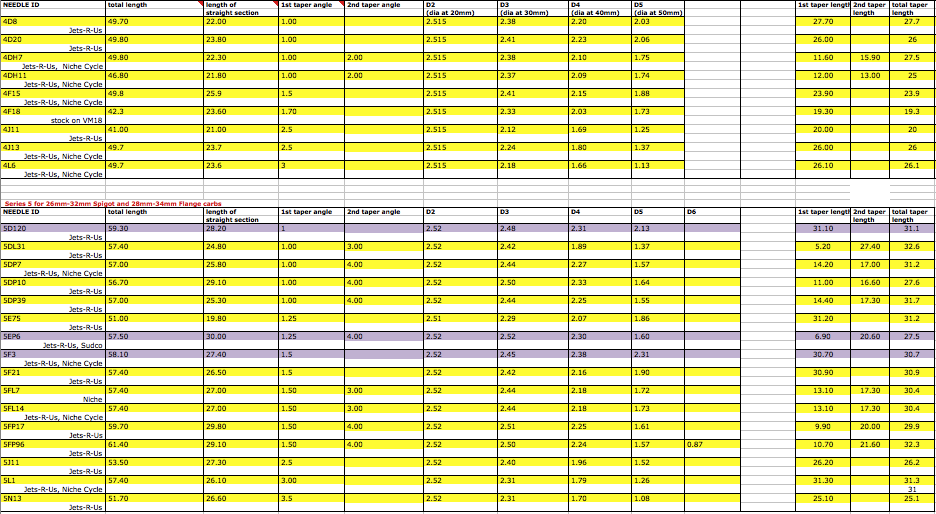

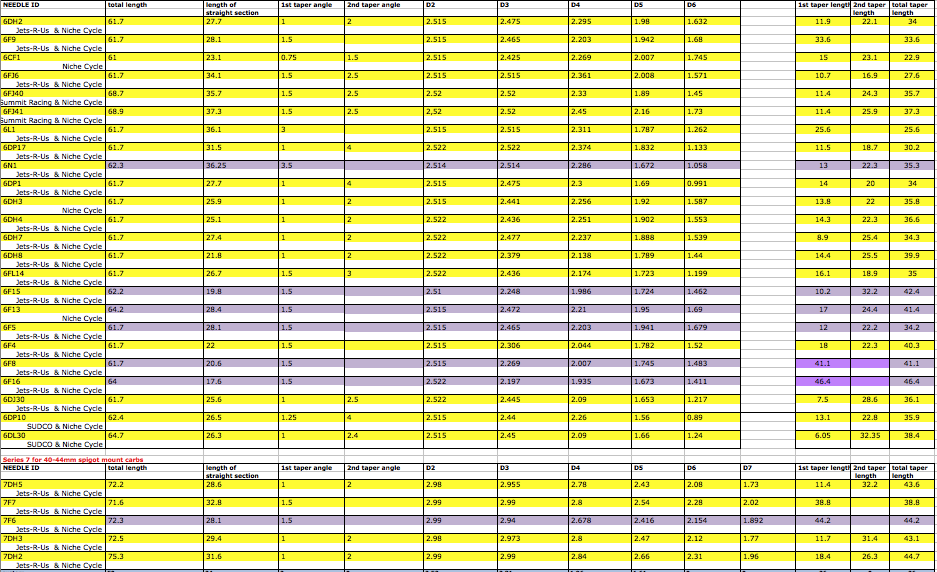

Listings of all the Mikuni VM needles: Sudco NicheCycle. Click here to downlad an Excel sheet which gives dimensions on absolutely all the Mikuni needles ever made. (The Mikuni needle data on my spreadsheet is even better than what they list because it has corrections for obvious errors they made in copying.) Here's what Mikuni VM's typically are equipped with.

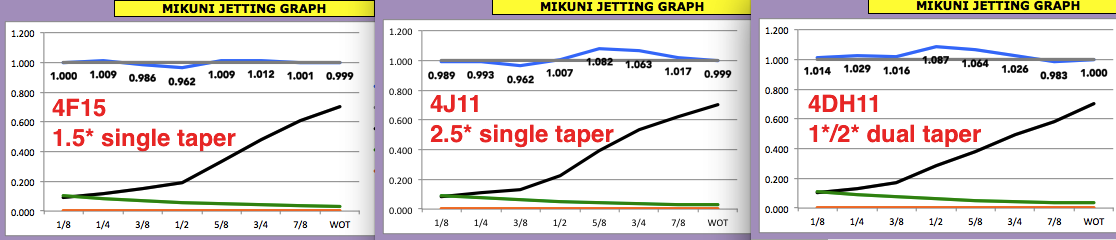

VM needles: Series 4 for VM18-24 carbs

Series 6 for VM30-38 spigot, TM38 carbs

Mikuni TM carbs :  TM NEEDLES TM24, TM28, TM32, TM34: 5D120 5FL14 5DP7 5F3 5L1 5F12 (lean --> rich) $7.04 TM24, TM28, TM32, TM34: 5DL31 5DP10 5DP39 5E75 5EP6 5F21 5FP17 5FP96 5J11 5N13 $7.04 TM33-8012 PUMPER CARB: J8-5FP96-3 $7.04 TM38 FLATSLIDE: 6DH2 6F9 6DH3 6l1 6DP1 6DH4 6DH7 6DH8 6FL14 6F15 (lean --> rich) $7.04 TM38 FLATSLIDE: 6DJ30 6DP4 6DP17 6F4 6F5 6F8 6F16 6F21 6FJ6 6FJ40 6FJ41 6FL25 6J1 6FM46 6N1 $7.04 TM36 TM38, 39 + 41 PRO SERIES: 6FJ41, 6FM46, 6FJ40, 6DP4 $7.04 Here's what Mikuni TM's typically are equipped with.

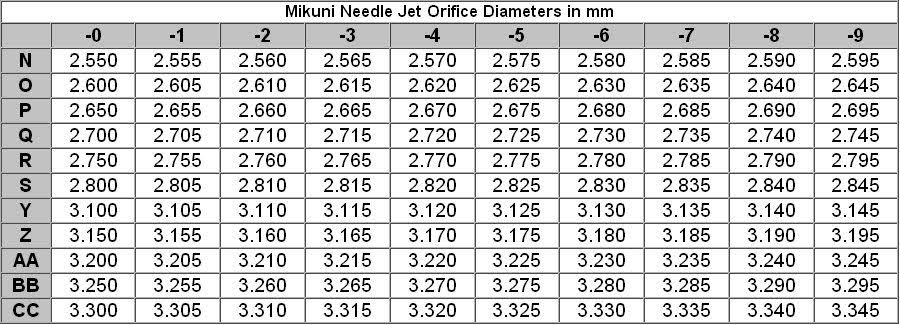

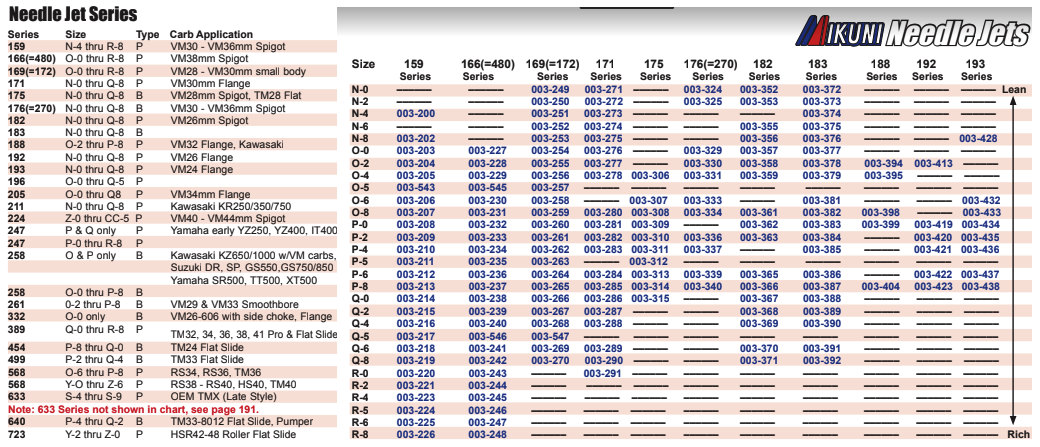

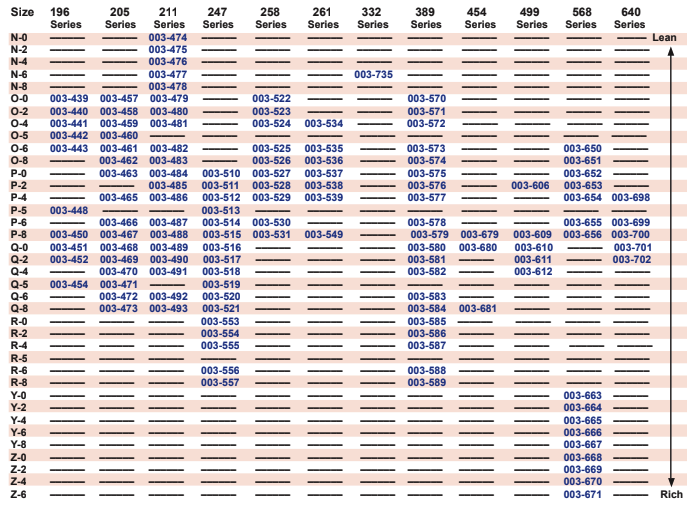

The normal #5 series of standard Mikuni needles are suitable for the TM34, and the #6 series is good for the TM36 to TM38 non-pumper carbs. Listings of all the standard Mikuni needles: Jets R Us (but theirs aren't all genuine Mikuni needles). NicheCycle and Sudco also have needles. SUDCO: VM carb parts, Mikuni needles, Mikuni jets, VM slides, TM carb parts. (The #5 and #6 data on my spreadsheet is even better because it has corrections for obvious errors in copying.) Each MIKUNI NEEDLE is identified by the letters and numbers stamped on them. Example: 6FH7 6 is the length, which in this case is more than 60mm but less than 70mm F is the top taper, A-E having less taper H is the bottom taper (sometimes the NEEDLE has only one letter, in that case it refers to a single taper) 7 is a mfg code not normally used in tuning. NEEDLE JETS Here's the chart showing the inner diameters of the jet holes:  This shows what needle jet series is used in each model carb and which ones are available from SUDCO. Ones for carbs under 24mm aren't available.  continued...  If you have any questions then just email me at a57ngel@yahoo.com |