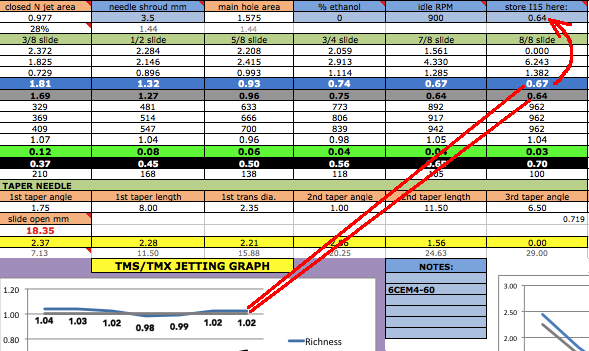

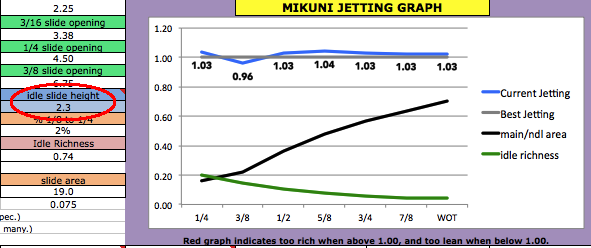

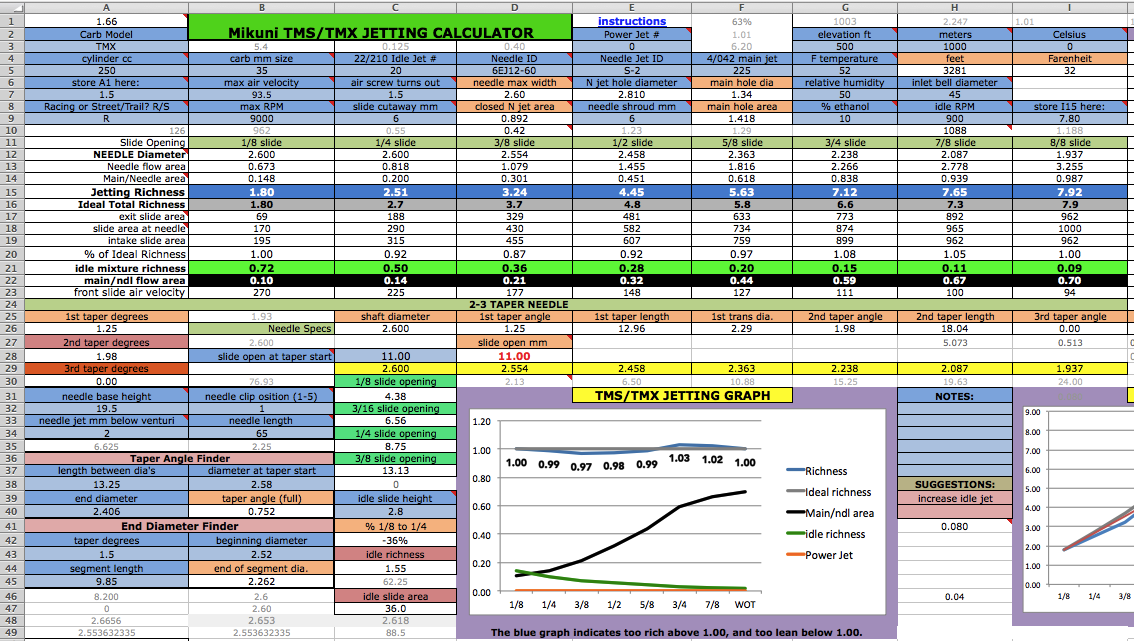

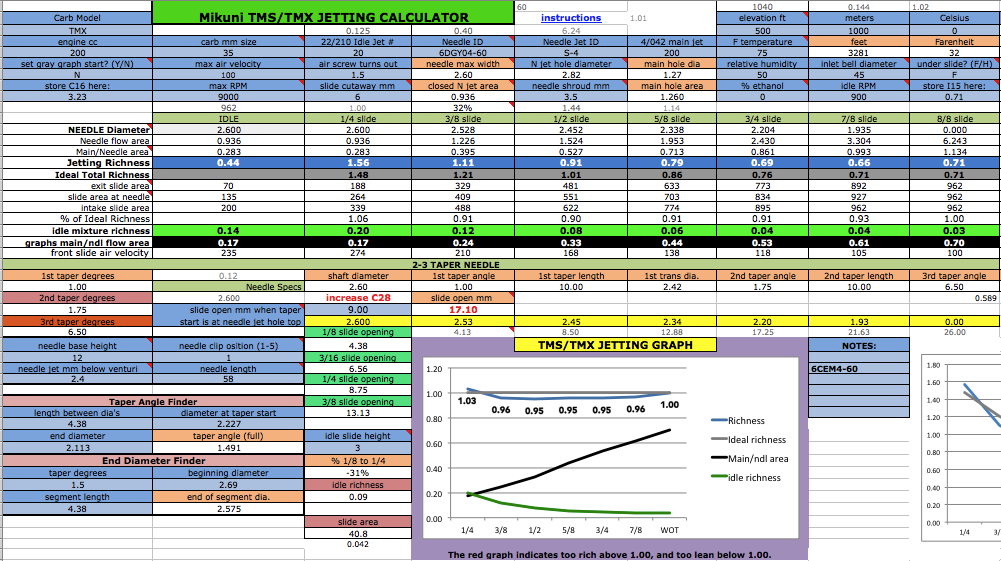

Jetting Mikuni TMS/TMX carburetors Below is a screenshot of my spreadsheet page for Mikuni TMS and TMX carbs. Here's how to use it. Enter all the data in the light blue data boxes for the program to automatically display the jetting results in a graph. If you hover the mouse pointer over a cell with a red corner then a message will pop up telling you about that cell.  At the bottom of this page are the links to the needle and needle jet info that you will need to know, such as the inner diameter of the needle jet of your carb. Starting at row 51 of the TMX sheet are all the needles and their data. Here's the sequence you need to follow: 1) First make sure your real life idle jet size is correct. Turn in the slide stop screw till you have a slightly fast idle. Then slowly turn the air screw till you find where it idles the fastest, then readjust the slide stop for the same fast idle as before if it has changed. Then slowly turn clockwise the air screw till the idle speed starts to drop off due to starting to be too rich (but which is good for starting w/o the choke in warm weather). This should result to be within 1 to 2 turns out. (Forget the untrue 1.5 turn "rule" which never came from the carb manufacturers.) If it is less than 1 turn then you need a bigger idle jet. If it is more than 2 turns then you need a smaller idle jet. Install the correct idle jet if necessary and repeat procedure, adjusting the idle air screw. Then turn the slide stop screw till you have a normal idle speed. The right idle jet is what gives these two things: 1) the most consistent idling when the engine is hot, 2) the best off-idle power as you open the throttle slowly. Later you can change the slide stop position, idle jet, and air screw setting to your own preference, the best example being that racers let the slide low enough for engine braking that is too low to allow the engine to idle. Normally if you have to make the idle mixture too rich for smooth idling in order to help compensate for weak throttle response as you crack the throttle open then you either have the needle clip in too high a position (lowered needle), the needle is too fat, or the needle jet (the brass hole the needle slides into) is too narrow. 2) Make sure your main jet is correct. The simplest method is to try a few jets and pick the richest one that allows clean WOT running. Click here to find out the best way to size the main jet. For small carbs you may need to cut down the needle shroud if one main jet size is too rich and the next smaller size is too lean. In that case put in the rich jet and then lower the shroud .5mm (.02") at a time till the jetting is right.

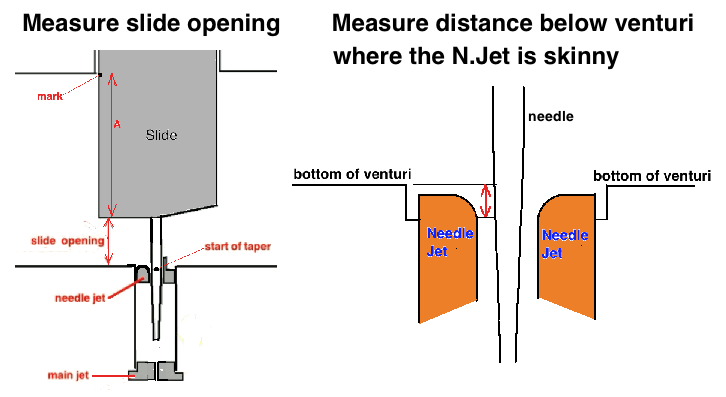

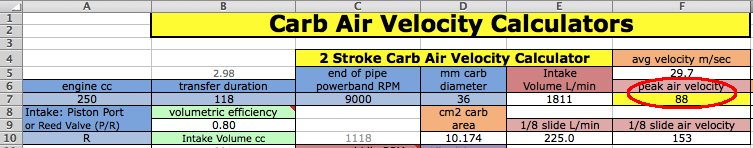

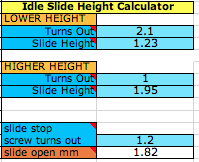

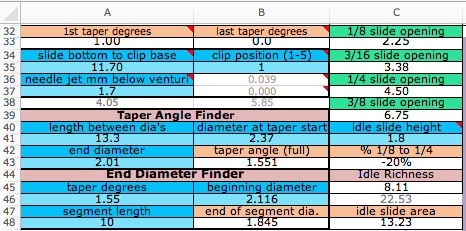

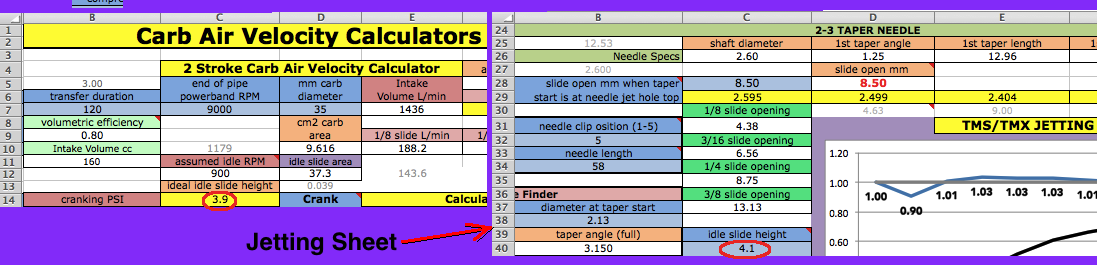

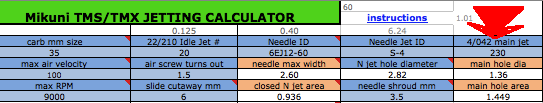

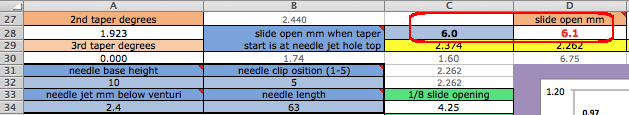

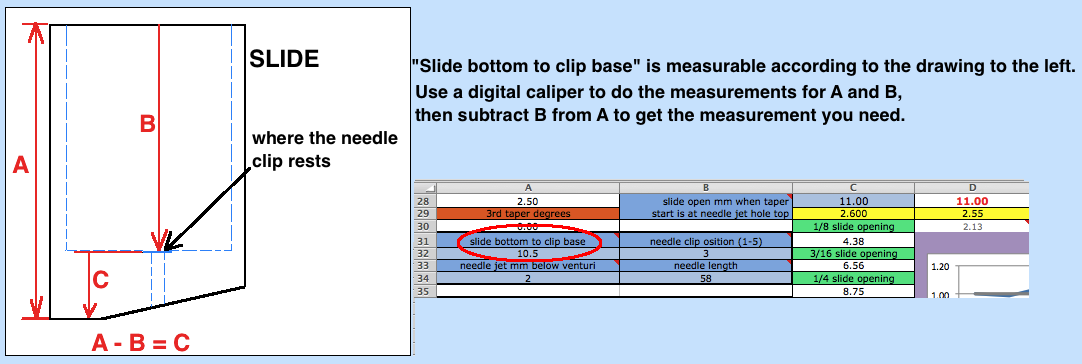

3) Go to the last sheet (click on the velocity tab at the bottom left of the screen) to find out the maximum air velocity to enter at B7 of the TMX sheet. If you aren't sure of the transfers duration then enter 125-130 for race engines or 115-120 for street/trail engines.  4) You'll need to set the slide stop screw for an even engine idle and then take the carb off and measure the idle slide height for C40 of the jetting sheet. That is hard to do and so I made a mini calculator on the 1st Mikuni sheet, N15 to O27, that allows you to use two allen wrenches, one of a size smaller than the slide open mm, and one larger than that to calculate what the slide opening is according to the turns out of the slide stop screw.    5) Enter the 4/042 main jet # at F5 on the TMX sheet.  6) At D5 you enter the needle ID (code) so the program can find the needle in the listing farther down the same sheet and use its data for the calculations. The ID is imprinted near the top of each needle. Data for a custom needle can be entered at rows 88- 91 if its needle data is missing. Give any custom needle a unique ID.

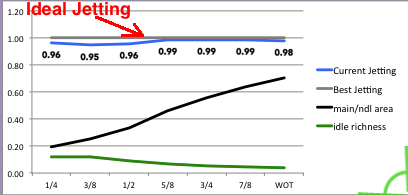

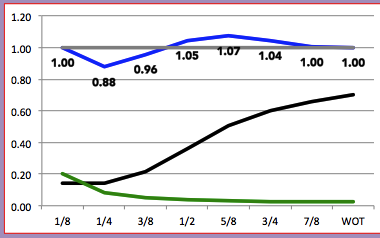

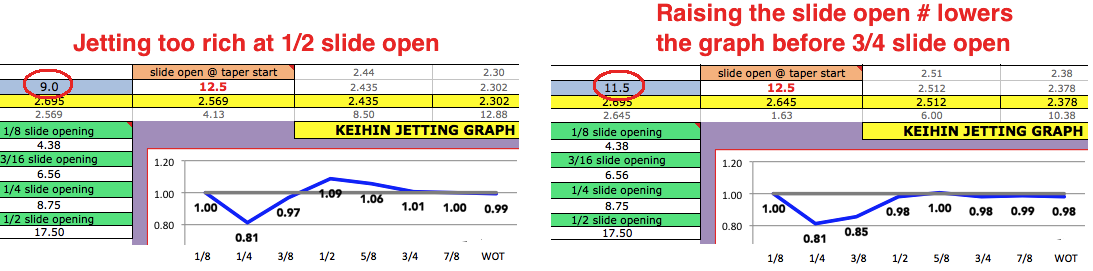

If the beginning graph is off from reality (blue too high or too low) then change the # at A7 to make it represent what you are feeling when reving and riding it. This will compensate for any bad measurements you've made or the idle circuit design varying from what is expected by the formulas.

12) After everthing is done, and the graph shows too lean or rich mid throttle than what you experience, then you'll need to adjust the graph with an adjustment factor at A9. 1 doesn't change it at all but higher than that (up till the max listed at A10) will bow upward the graph before WOT. This page tells the correct procedure for evaluating the jetting. 13) Re-record this spreadsheet with all of your data in it. For example, if saving data for a YZ250 then save it as JettingCalcYZ250.xlsm

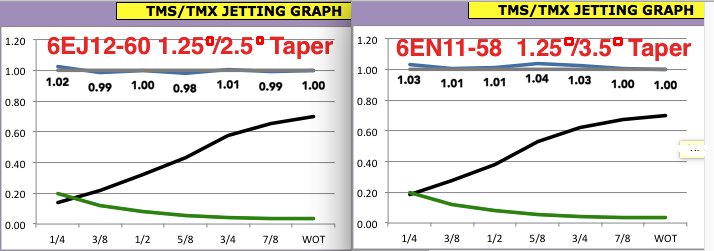

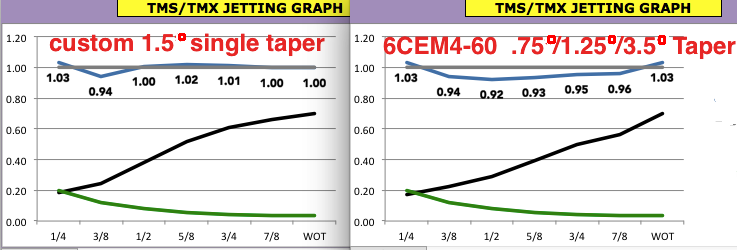

Here's what the carbs usually come equipped with:  TMX + TMS needles:

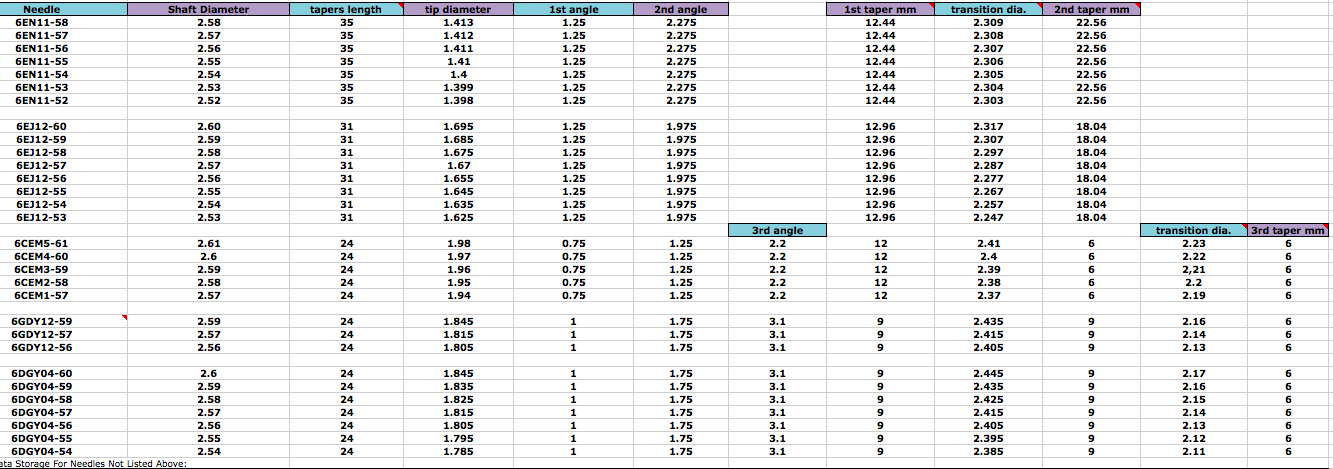

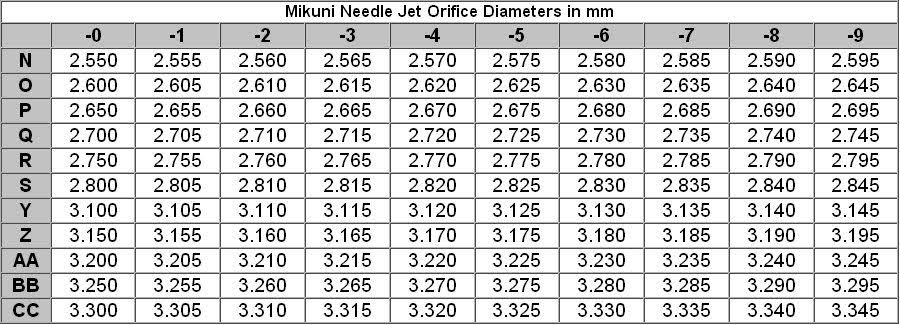

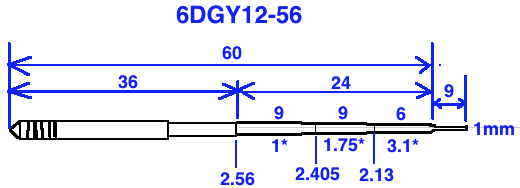

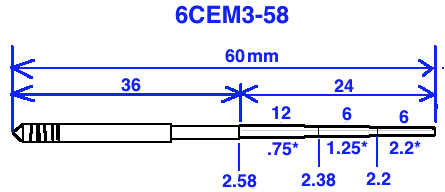

If you aren't sure what needle jet is in your carb then you'll have to get an idea what size opening the needle jet has by inserting different size drill bits into it unless of course you can unscrew it from the carb. What SUDCO stocks is series 633 S-4/7/8/9, and series 914 S-9.   This is from the Jets R Us website concerning needle jets for the TMX. S-7 has an inner diameter of 2.835mm so if your needle jet is not removable and is impossible to measure then just use that diameter by entering S-7 at E5. That should be close enough to reality.  TMS/TMX Needles from Jets-R-Us: EARLY STYLE TMX35 FLATSLIDE: 6EN11-(52/53/54/55/56/57/58) $7.04 EARLY STYLE TMX38 FLATSLIDE: 6EJ12-(53/54/55/56/57/58/59/60) $7.04 TMS38-77, 78 125cc: 6GDY12-(56/57/59) $7.04 TMS38-77, 78 250cc: 6DGY04-(54/55/56/57/58/59/60) $7.04 TMS 38-78: 6CEM(01/02/03/04/05) $12.04 Example Mikuni TMS needle: 6DEY26-66 The first 6 is the length, which in this case is more than 60mm but less than 70mm The -66 translates to the straight part of the needle. Divide it by 100 and add to 2 so that 66 = 2.66mm in diameter. And 6DEY26-67 = 2.67mm dia. Other options: 6DEY27-66 is a 1/2 clip richer than a 6DEY26-66 Letters DEY indicate triple taper needle. D=1 degree taper, E=1.25 degree, Y=3.1 degree. A=0.25 degrees and increase by .25 degrees per letter increase till G, thereafter the letter increase is .075mm each. Two letters indicates dual taper, and three letters indicates three tapers.   SUDCO has a complete listing of parts, jets, and needles for the TMS and TMX carbs. Their needles are probably machined more precisely than those from Jets-R-Us since all the needles I have bought from Jets-R-Us aren't to spec. I can be contacted at a57ngel@yahoo.com |