|

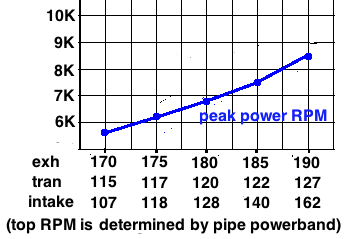

Don't allow compression loss from incorrect head gasket sealing. It can't seal right if the head or the cylinder is warped. Plane them down on sandpaper on glass. Much better than the stock aluminum gasket is one you can make from gasket material from Autozone. Take 1mm to 1.5mm off the stock cylinder head for more engine compression and power. If it's too much work then just take it to a machine shop to do it on a lathe. For a 48cc you can reduce ring drag with thinner rings by replacing the stock piston/rings with a Yamaha Jog 50 piston/rings if your engine has a reed valve (because the piston has an intake window) and an iron sleeved cylinder (because this pistons rings are chromed and will damage a chromed cylinder. Chromed cylinders need non-chromed rings.). Cut the intake and exhaust skirts to 46mm long to keep it from hitting the flywheels. Click here to read more. For 66cc: Click here for my page about the Minarelli piston and Motobecane rings I recommend. Replace the upper connecting rod bearing (since the stock one will wear out very quick with increased cylinder pressure) and the stock piston wrist pin with a lighter one (because the inner hole diameter is larger) to reduce engine vibration. I used to give specific porting advice but now the cylinders vary a lot and you just need to buy a digital caliper and measure the distance above ports and find the "deck" and use an online port duration calculator to know the durations. Use this guide to decide on what durations you want. With an expansion chamber the top RPM is about 1500 more than the engines raw peak power RPM. So with an exhaust duration of 175 and transfer duration of 117 then expect 6200 RPM peak power and with an expansion chamber with correct length you'll get around 7200 RPM max. Click here for my porting page. Defintely consider making transfer ramps on your piston for the best power.  Make the exhaust port 70% the width of the bore (measuring straight across, or 75% measuring from paper impression) and the intake port 2mm wider on each side. Add JB Weld to the front walls of the transfer ports so the entry angle of the fuel/air is aimed rearwards and not straight across at each other. [info] Use your rotary tool to grind away at the rear of the transfer ports so that they are at least 2mm more rearward. [info] Install a motorcycle ignition coil and CDI for more power and less vibration and less wear on the conrod bearings and less cylinder plating flaking off due to excess cylinder compression due to excessively advanced ignition timing from the stock CDI. If you want to emphasize low rpm power then install a rubber hose between the carb and the intake manifold so that the carb slide is at least 6+3/4" from the piston. [info] Also welding in a 6" exhaust pipe extension helps a lot. Piston Port Intake I've tested both intake systems back to back and got the same results so don't think you have to buy a reed valve to get the best power. You'll probably have to cut the pistons intake skirt shorter to get an intake duration between 115 and 120 which is the best range for street use. If you port it to rev to 10K or more then you should go to 125 degree intake duration. Click here to see my video about the two intake types. Reed Valve Intake Best idling and low intake noise are the advantages of a reed valve. You can buy a Rock Solid reed valve, drill holes in your piston if it doesn't have any, and dremel a boost port in the cylinder. [info]

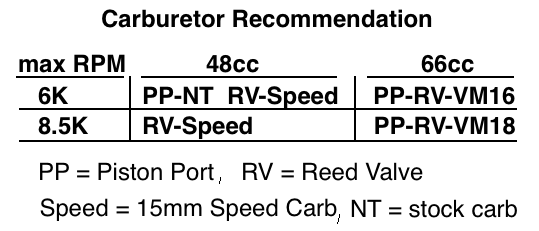

Here are my recommended carb sizes which comes from my carb sizing calculator which takes into account engine compression, cylinder bore, intake type, engine size, RPM. If you want to race then just add 6mm to the carb size. The VM16 and VM18 are Mikuni's and the links to them are on my available carbs page.

Here's 3 options for a better exhaust pipe: A. Cut the pipe 1" from where if connects to the muffler and add a 6" long metal pipe (3/4" I.D.) to extend the pipe. [info] B. Make your own extended baffle expansion chamber for best low rpm power. C. Buy an expansion chamber and cut the baffle cone and weld in a 2" baffle extension.

If the engine vibrates then drill two 10mm holes in the crank flywheels above the con rod pin (at same radius of existing holes) to eliminate the engine vibration. Use a strong carbide drill bit. |