Jetting Keihin carburetors

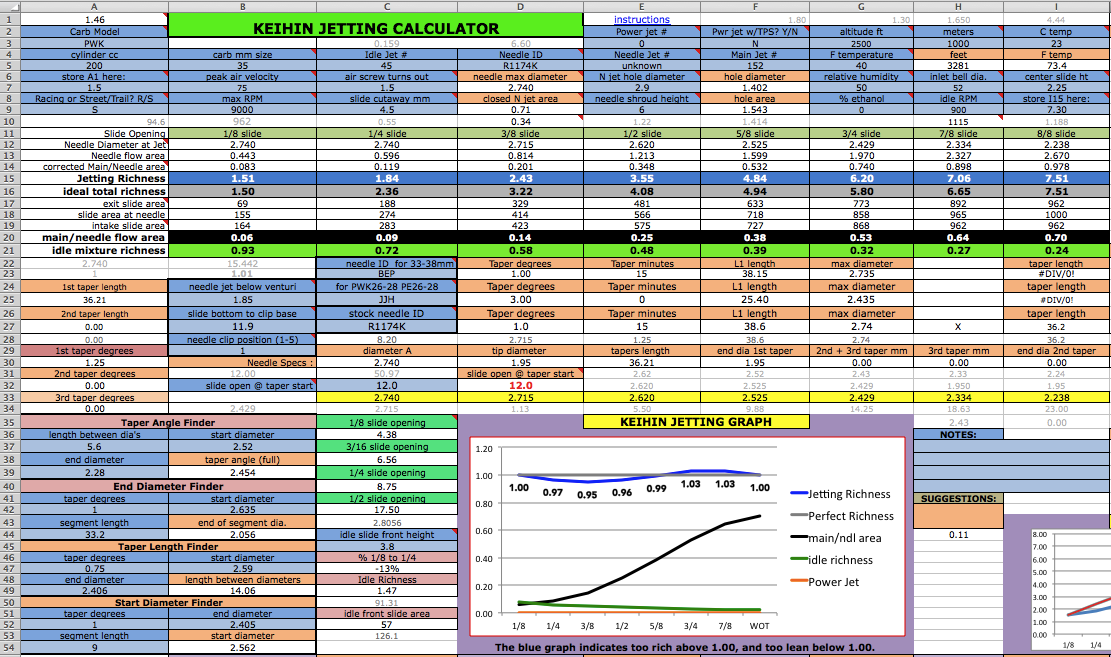

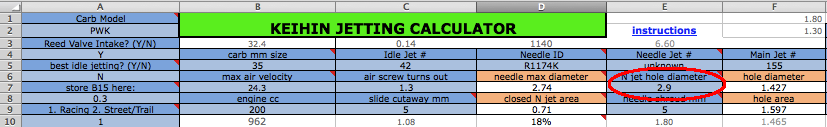

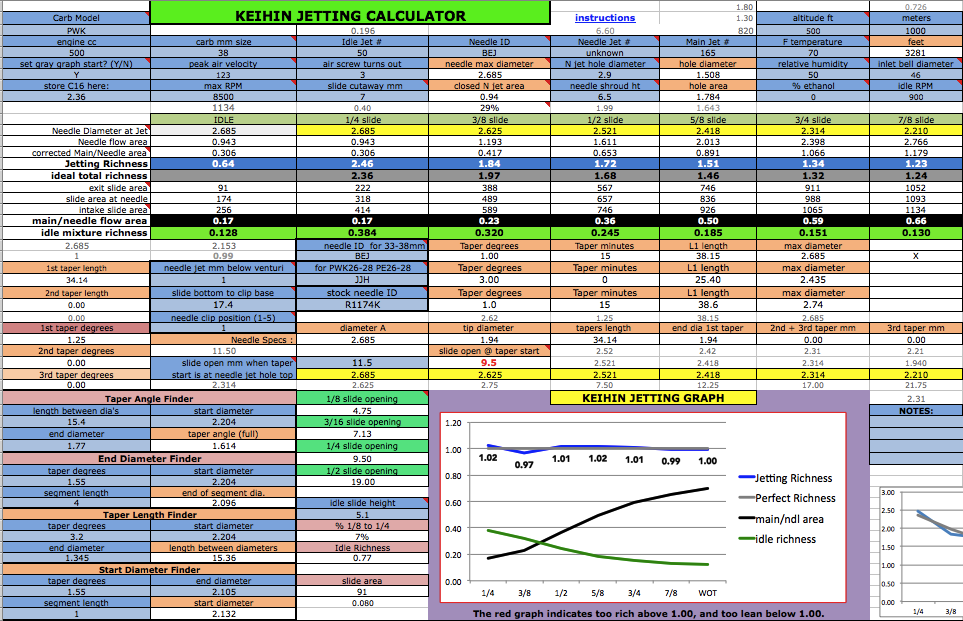

Below is a screenshot of my spreadsheet for Keihin carbs (PWK, PJ, PE). Below the instructions here are the needle and needle jet info that you will need to know such as the inner diameter of the needle jet of your carb. Here's how to use it: Enter data into all the light blue cells of the spreadsheet and the program will graph the jetting. If you hover the mouse pointer over a cell with a red corner then a message will pop up telling you about that cell.  Here's the sequence to follow: 1) First make sure your real life idle jet size is correct. Turn in the slide stop screw till you have a slightly fast idle. Then slowly turn the air screw till you find where it idles the fastest, then readjust the slide stop for the same fast idle as before if it has changed. Then slowly turn clockwise the air screw till the idle speed starts to drop off due to starting to be too rich (but which is good for starting w/o the choke in warm weather). This should result to be within 1 to 2 turns out. (Forget the untrue 1.5 turn "rule" which never came from the carb manufacturers.) If it is less than 1 turn then you need a bigger idle jet. If it is more than 2 turns then you need a smaller idle jet. Install the correct idle jet if necessary and repeat procedure, adjusting the idle air screw. Then turn the slide stop screw till you have a normal idle speed. The right idle jet is what gives these two things: 1) the most consistent idling when the engine is hot, 2) the best off-idle power as you open the throttle slowly. Later you can change the slide stop position, idle jet, and air screw setting to your own preference, the best example being that racers let the slide low enough for engine braking that is too low to allow the engine to idle. Normally if you have to make the idle mixture too rich for smooth idling in order to help compensate for weak throttle response as you crack the throttle open then you either have the needle clip in too high a position (lowered needle), the needle is too fat, or the needle jet (the brass hole the needle slides into) is too narrow. 2) Make sure your main jet is correct. The simplest method is to try a few jets and pick the richest one that allows clean WOT running. Click here to find out the best way to size the main jet. For small carbs you may need to cut down the needle shroud if one main jet size is too rich and the next smaller size is too lean. In that case put in the rich jet and then lower the shroud .5mm (.02") at a time till the jetting is right. [Plug Reading]

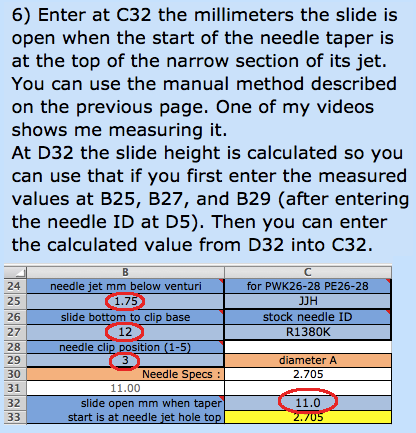

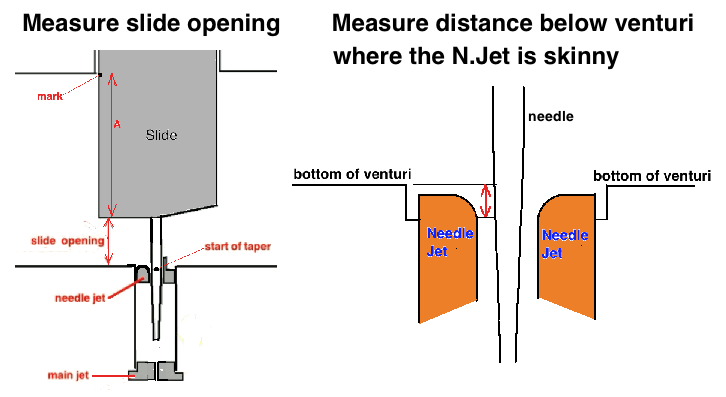

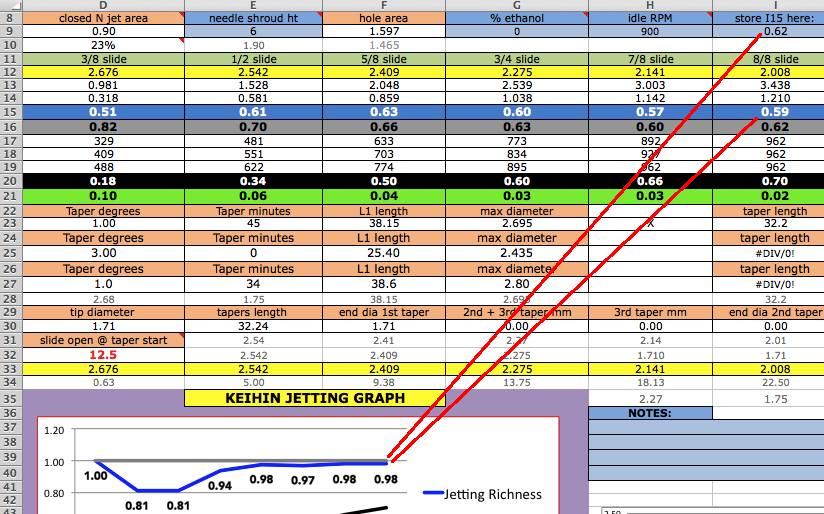

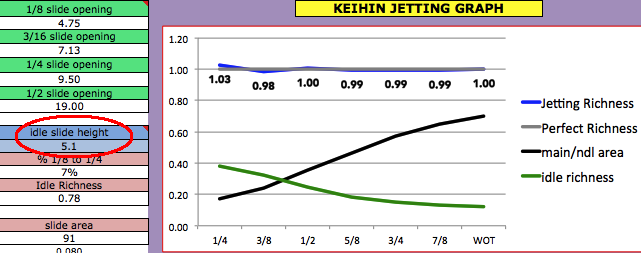

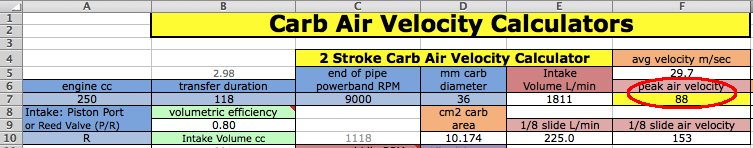

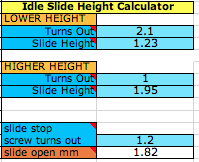

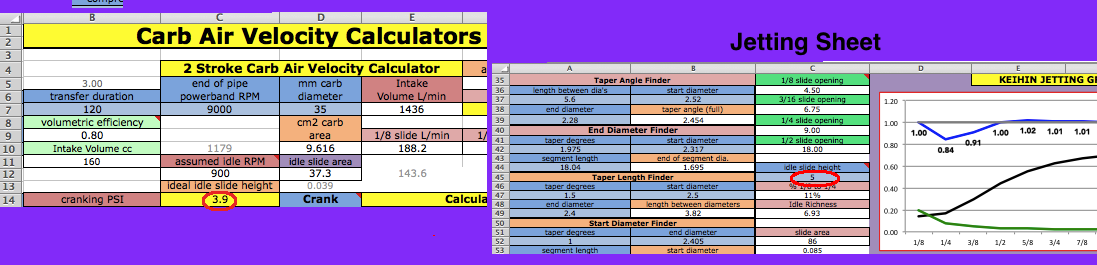

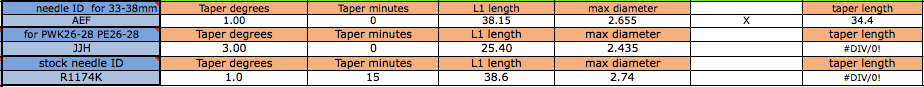

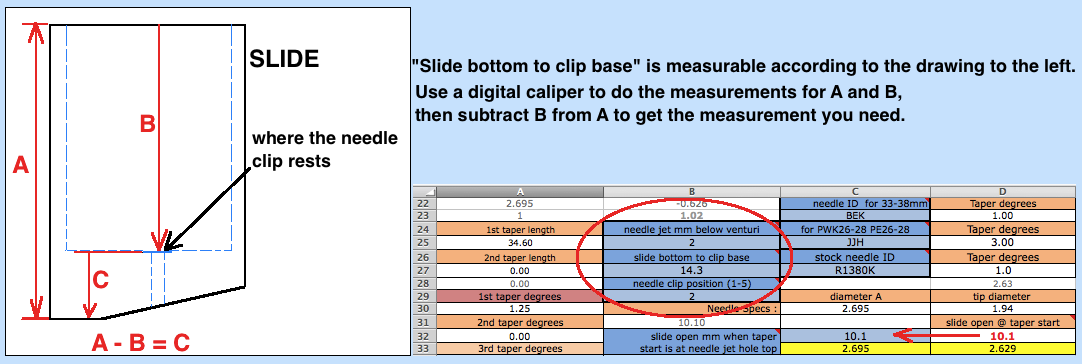

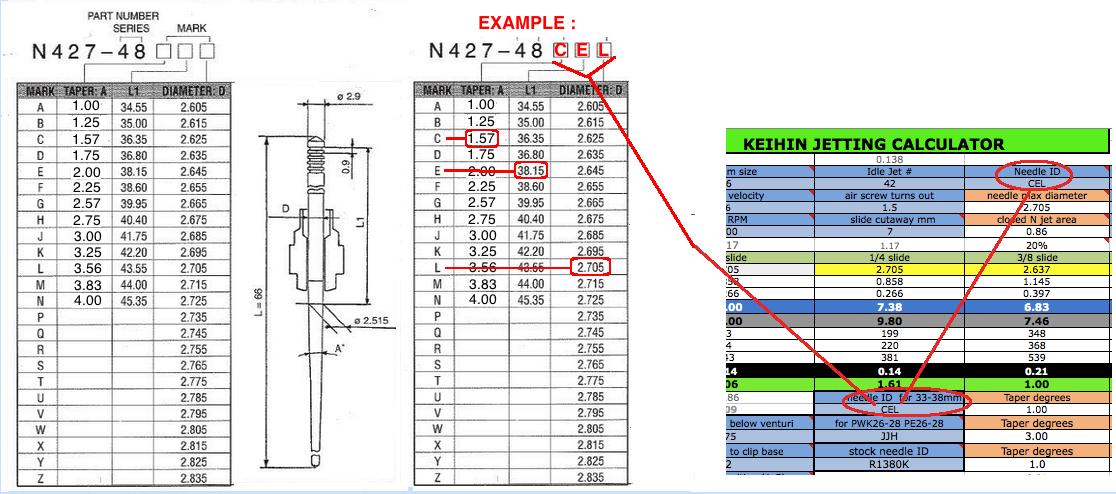

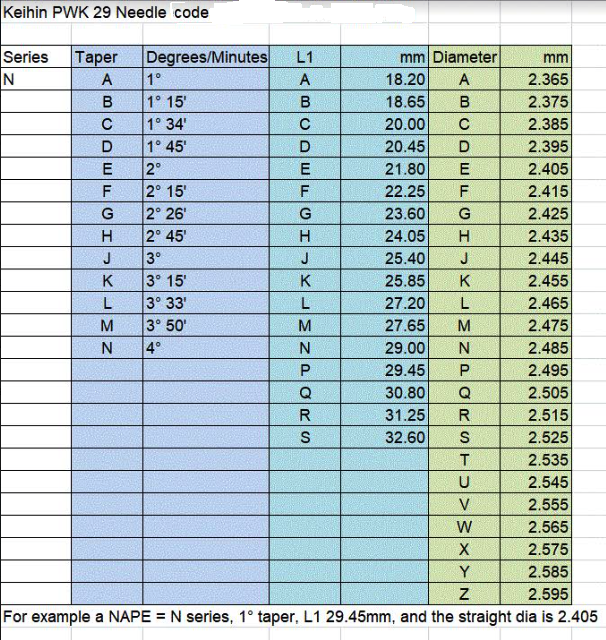

3) Go to the last sheet (click on the velocity tab at the bottom left of the screen) to find out the maximum air velocity to enter at B7 at the Keihin sheet. If you aren't sure of the transfers duration then enter 125-130 for race engines or 115-120 for street/trail engines.  4) You'll need to set the slide stop screw for an even engine idle and then take the carb off and measure the idle slide height for C45 of the jetting sheet. That is hard to do and so I made a mini calculator on the 1st Mikuni sheet, N15 to O27, that allows you to use two allen wrenches, one of a size smaller than the slide open mm, and one larger than that to calculate what the slide opening is according to the turns out of the slide stop screw.   5) Look at the 3 needle types at section C23 to C27 and if you want to graph a needle that is within that group then enter its code and then enter the same needle code at D5. Or ignore the section from C23 to C27 and just enter at D5 a needle code for one of the needles listed from B56 to B105. Or enter the data for a custom needle starting at B107 and enter at D5 whatever you named it. For the 3 letter needles (ie: DEK) the 1st letter indicates the taper angle, the 2nd letter the L1 length, and the 3rd letter the maximum diameter. At the right side of the sheet you can see the code breakdown starting at the J column. For OEM needles (example: R1172J) the 1st pair of numbers is the taper angle, the 2nd pair of numbers the diameter, and the last letter the L1 length.  The needle jet (the hole that the needle fits in) diameter for E7 is 2.9mm for PWK33-39mm, PJ34-38mm, PE36, PWM38. And it's 2.6mm for PWK26-28mm, PE26-28, PE20-24. Enter the appropriate diameter at E7.

If the beginning graph is off from reality (blue too high or too low) then change the # at A7 to make it represent what you are feeling when reving and riding it. This will compensate for any bad measurements you've made or the idle circuit design varying from what is expected by the formulas.

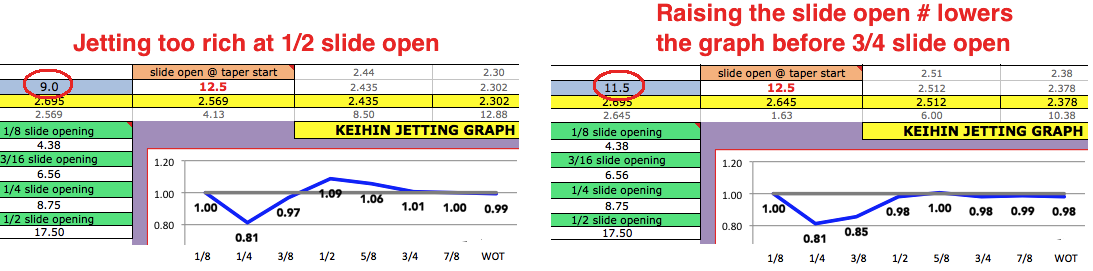

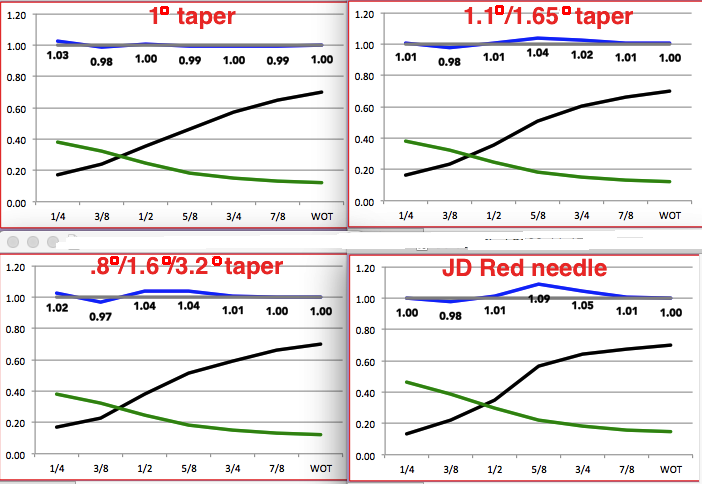

Multi-tapered needles are often too rich at 1/2 or 5/8 slide opening. If you feel that is the case then find a single taper needle to use.

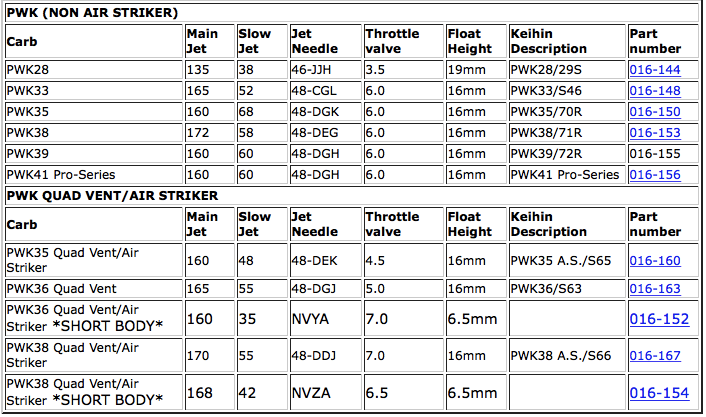

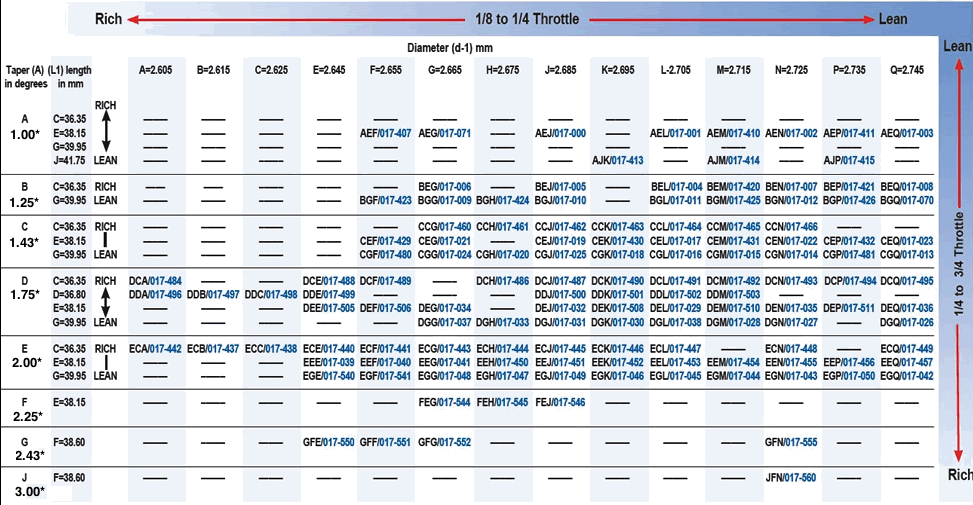

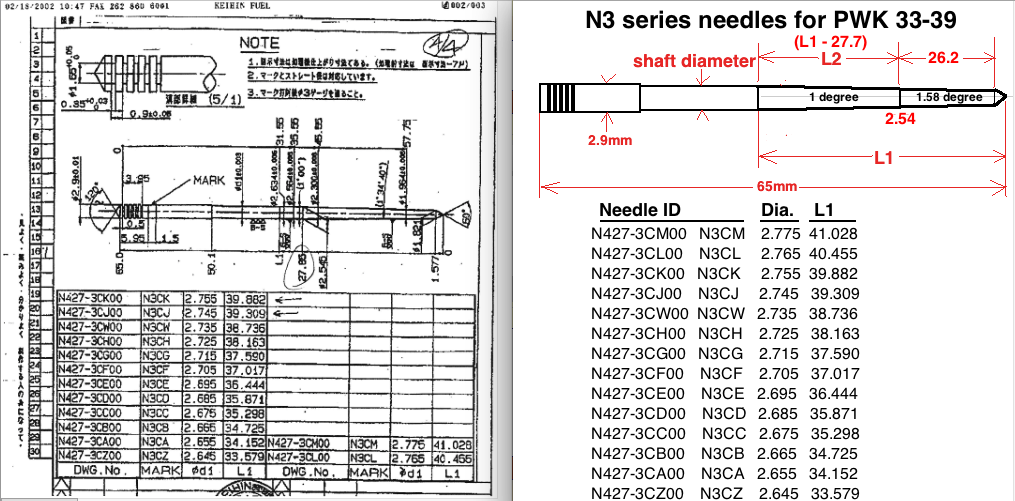

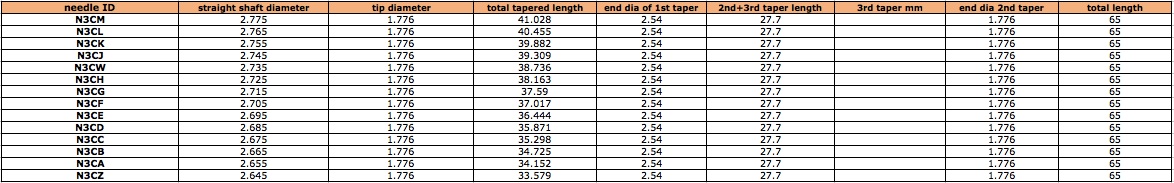

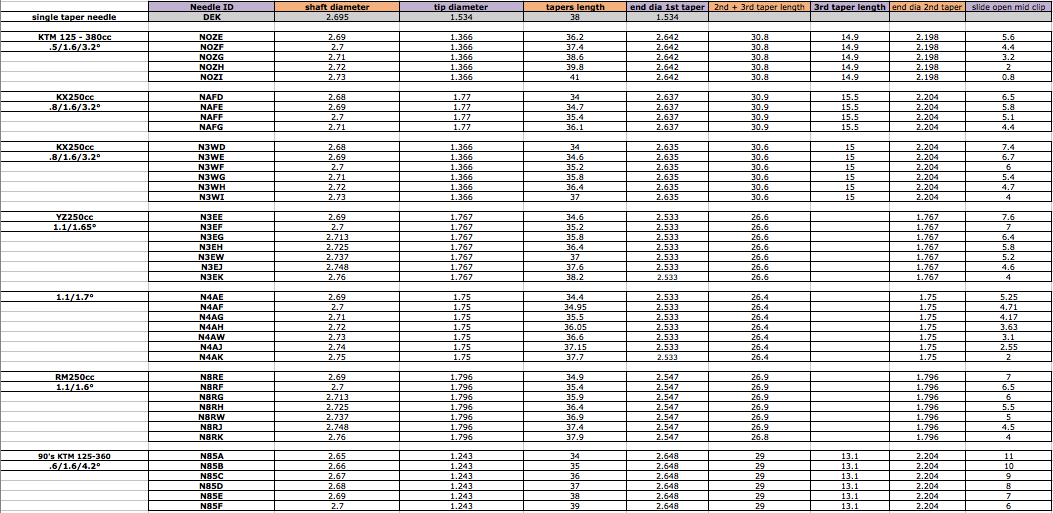

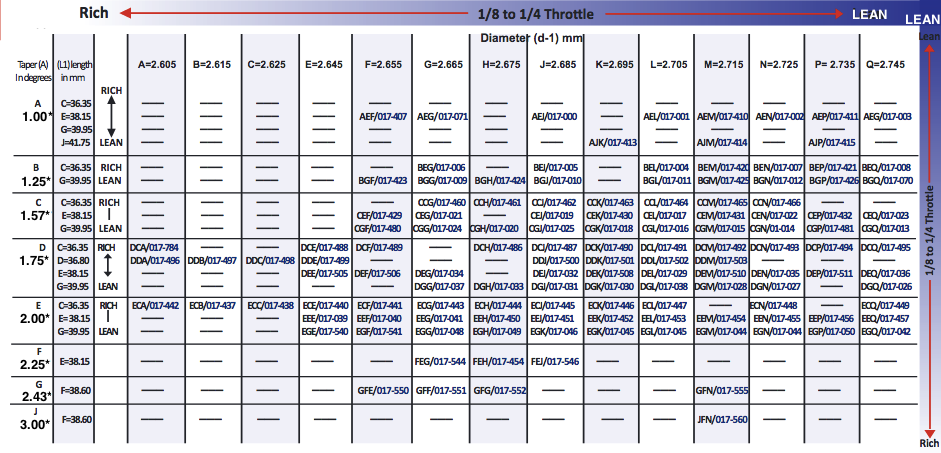

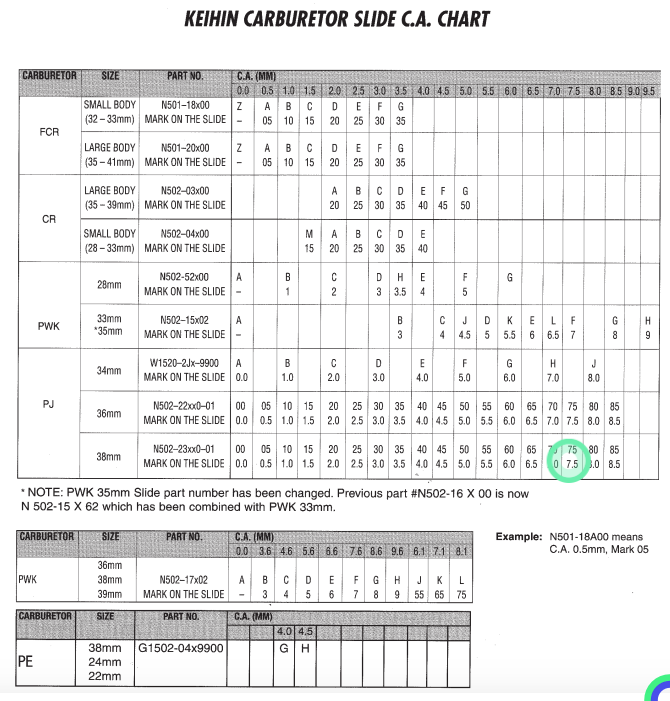

11) After everthing is done, and the graph shows too lean or rich mid throttle than what you experience, then you'll need to adjust the graph with an adjustment factor at A9. 1 doesn't change it at all but higher than that (up till the max listed at A10) will bow upward the graph before WOT. This page tells the correct procedure for evaluating the jetting. 12) Re-record this spreadsheet with all of your data in it. For example, if saving data for a YZ250 then save it as JettingCalcYZ250.xlsx  Keihin needle jet inner hole diameters 2.9mm for PWK33-39, PWM38, PJ34-38, PE36, FCR28-41 2.6mm for PE26-28, PWK26-28, PE20-24 Heres what PWKs are often equipped with:  Needle Data for PJ34-38 PE35-38 PWK33-39 PWM38 from Jets R Us: The 48 series are for the large PWK carbs. The 46 series are for the smaller ones. This shows that you just use the last 3 letters of this code.  As an example look at the top left needle which is AEF. The first letter refers to the needle taper degrees/minutes, the second letter to the L1 length, the third letter to the diameter. So AEF has 1 degree 0 minutes (1.0 degrees), 38.15mm L1 distance, and 2.655mm needle diameter (at the straight section). CEJ has the degrees increased by 34 minutes (34/60=.57 degrees), same length, and diameter increased by .02mm for a leaner mixture at low throttle settings.     Here's Keihin's engineering drawing for the N3 series needles for the PWK33-39. They all have the same dual taper but vary in upper width.  I just lately came across the N3C data and don't conveniently have the room to squeeze it into the program so I put it at the bottom of the spreadsheet (starting at row 183 although the calculator doesn't access that data) and you'll have to enter any of their data in as a custom needle at one of the rows from 107 to 111. For all other 65mm needles you can follow instructions at my video to find their specs to enter into this spreadsheet.

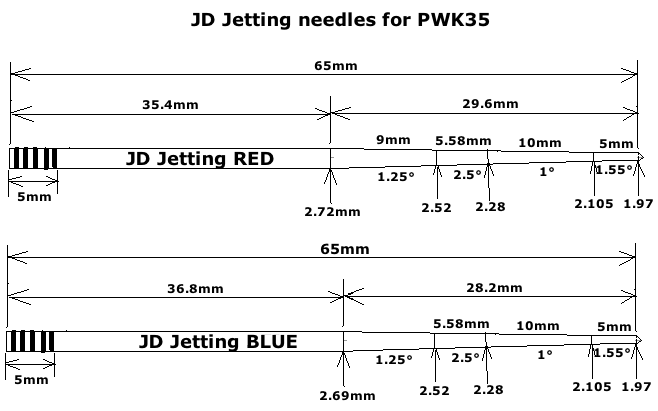

Analyzing the needle diameter graphs on the JD Jetting Spreadsheet I came up with these specs on the listed needles which are now programmed into the Keihin sheet on my jetting calculator.

Needle Data for PE26-28 PWK26-28 from Jets R Us :  Needle Data for PE20-24 from Jets R Us :

Keep in mind that the L1 length is not the length to the beginning of the taper but is the distance to where the taper will have a 2.515mm diameter. With needles that have a max diameter less than 2.515 then that L1 spot is actually imaginary, as if the taper kept extending upwards past the taper start. Needles with less than 2.515mm diameter: PE26-28, PWK26-28, and most needles for PE20-24mm. This was the explanation given to me by Jets-R-Us. Here's the needle code list for the rare needles for the PWK29:  Main jets and needles are also available from Sudco which is a preferred source for genuine Keihin parts. Just look at the main menu and then type in the page # you want in the upper left hand corner. These needles are for carbs PWK33-39, PJ34-38, PE36, PWM38 :  Slide Cutaway Info:

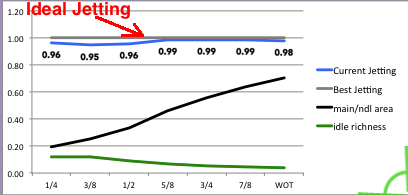

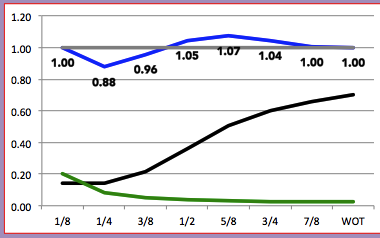

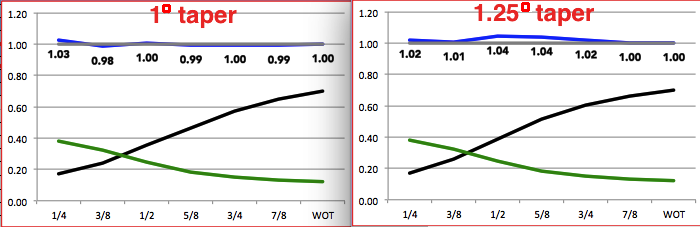

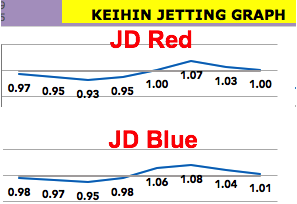

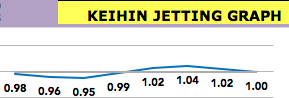

JD Needles  Supposedly the experts at JD Jetting sell a custom made needle that is supposed to be ideal for the PWK carbs. But a person just consulted with me for better jetting and he measured it all and I figured out its angles of its 4 tapers and when I plugged its specs into my jetting calculator the result was really rich at 3/4 slide open. There are better standard needles that work better such as the lowest graph here. What is ironic about this bitter tale is that the spreadsheet by JD Jetting is what I used many years ago to find a better needle for my '89 Honda CR250. It was a good program but it only compared needles so you had to be experienced enough to know what part of the needle needs to be fatter or skinnier. About a year ago I asked if he could share his needle data with me since he no longer sells his spreadsheet and he said no and then broke off communication with me. I thought that was pretty stinky but by using his calculator I was able to logically derive the needed specs from a slew of needles he had programmed into his spreadsheet. He could of been nice and just gave them to me but instead he made me work for hours to get them. So now I have the full story. Any way here are the jetting graphs. On them the grey line represents perfect jetting and the blue graph is the jetting the needle delivers.  Jetting graph of a commonly available needle for the PWK:

If you have any questions then just email me at a57ngel@yahoo.com |