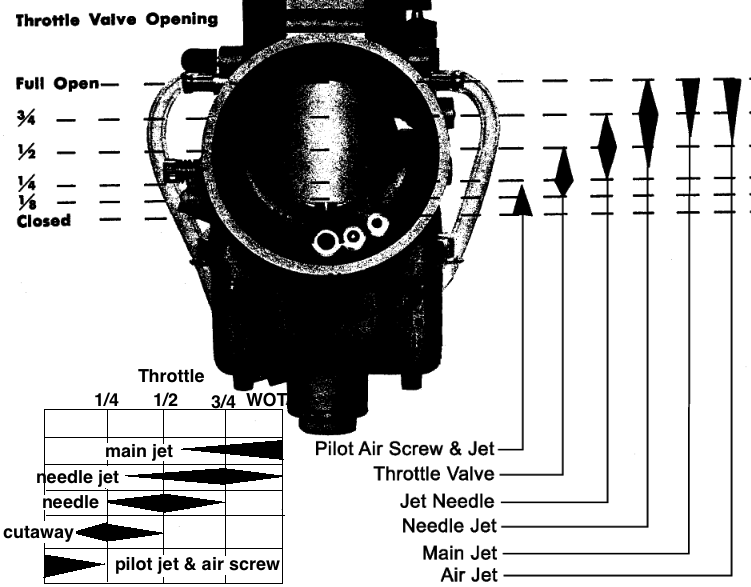

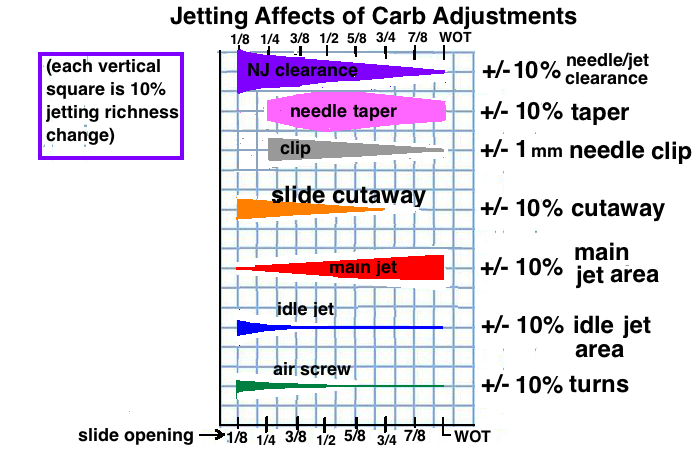

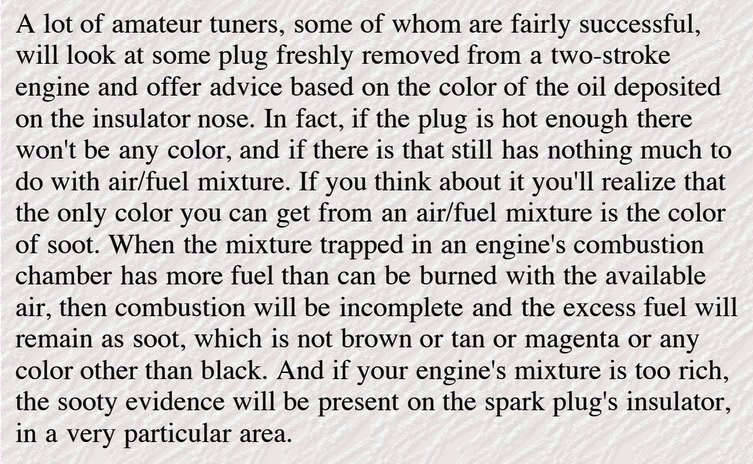

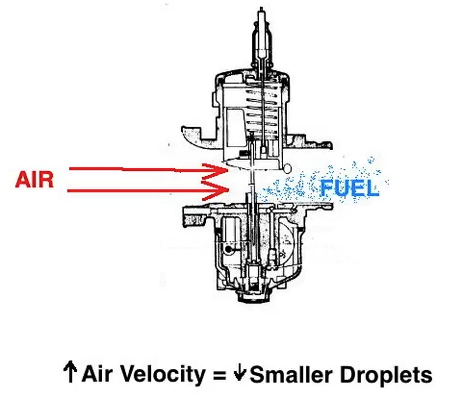

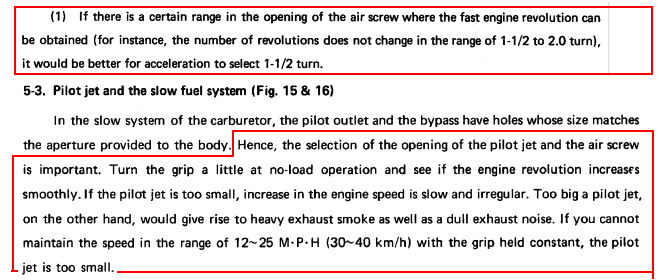

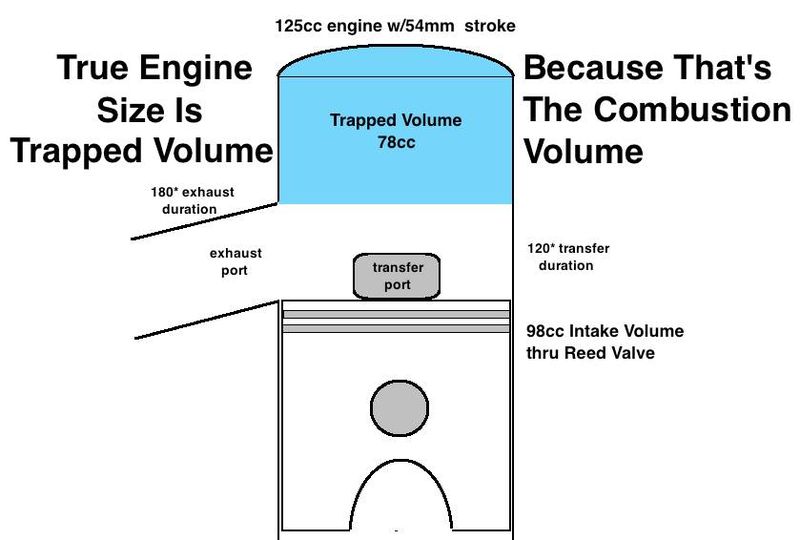

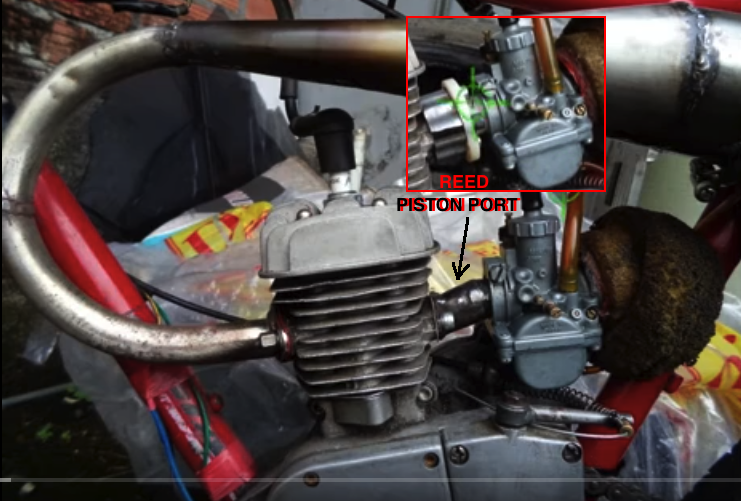

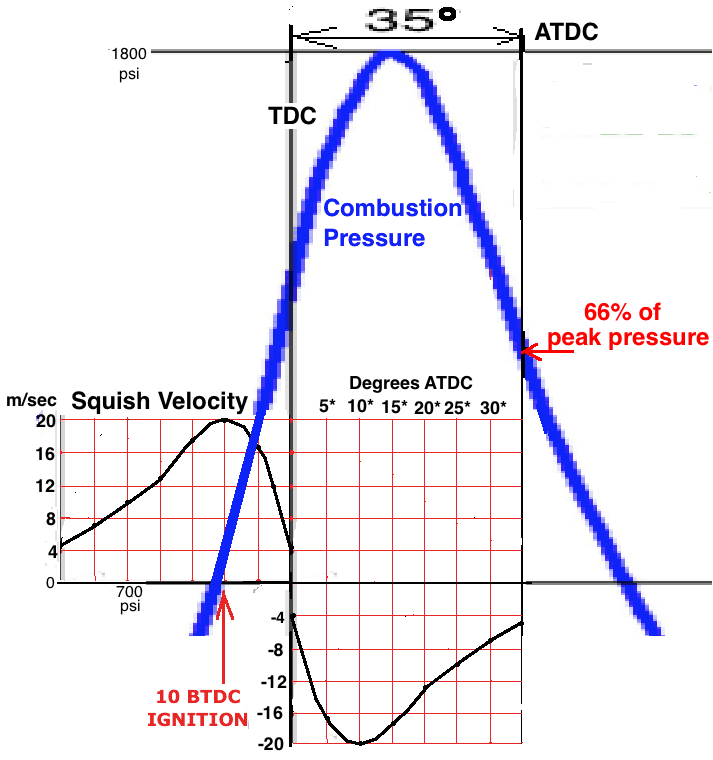

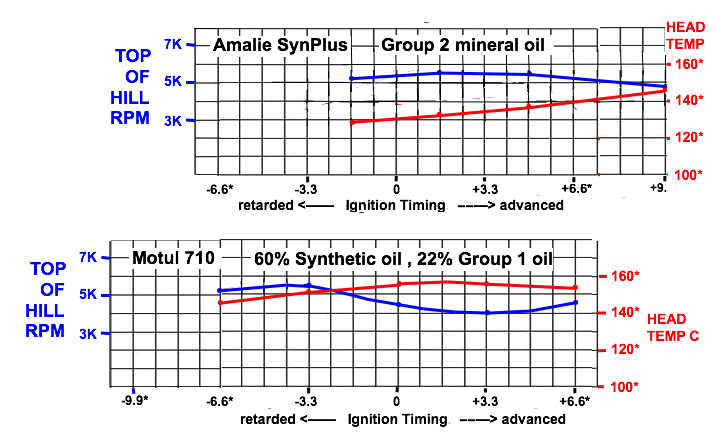

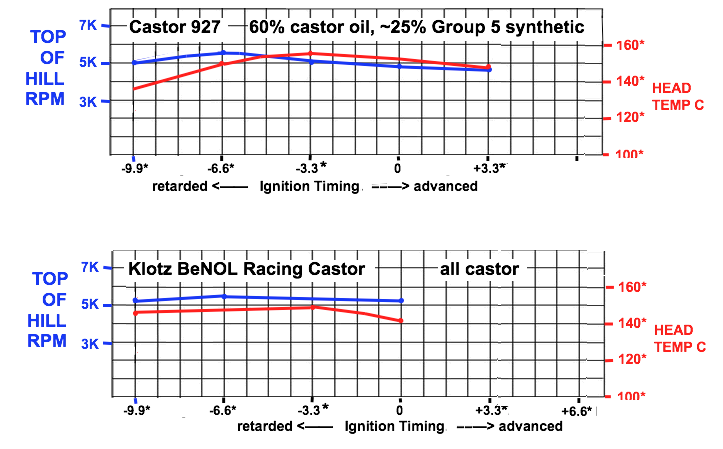

| The Most Common Myths: 1. The old carburetor jetting charts are accurate2. 32/1 is the best fuel/oil ratio 3. a medium brown/tan color spark plug indicates correct jetting 4. small carbs limit power by restricting air flow 5. 1+1/2 air screw turns out always indicates the best idle jet size 6. you can balance a crank using the balance factor method 7. the engine size is what the manufacturer says it is 8. reed valve engines are faster than piston port engines 9. Fuel/Oil ratio changes affect gasoline % significantly 10. the air/fuel under the squish band burns too late to contribute to power 11. Piston Port Causes Rich Jetting Due To Intake Reversion 12. Engine Oil Type and Amount Only Affects Lubricity Carb Charts Here's what Mikuni had in their old manual which shows the main jet not having any influence below 1/2 throttle, the needle jet not affecting idle, and the needle not affecting WOT.  Now look at this modern chart based on modern jetting calculators and how much different it is. You can see that the needle width (in relation to the needle jet) and the main jet has an effect thru the whole range, how the needle taper angle affects all thru WOT, and how the slide cutaway affects thru 5/8 slide opening.  Anyone could counter with "yeah but your jetting calculator could be wrong" which is a good counter argument. But my source of information comes from my own experience, the experience of others, and feedback from Jets-R-Us and SUDCO. If you don't believe me then ask them. Or do your own tests like sealing the main jet with silicone sealant (easily removed later) to see how much that change affects the engines ability to idle. Or change your needle for one with a different taper and see how that changes WOT jetting. Or take out the main jet and see how 1/2 throttle jetting will become too rich. OIL RATIO The correct amount of oil needed depends on oil viscosity, max RPM, type of cylinder cooling, and type of riding. Listing one recommended oil ratio is complete nonsense. There are generally 3 types of oils: moderately refined petroleum oil, synthetic oil, and a semi-synthetic blend of the two types. A typical ratio for petroleum oil is 25:1 and a typical ratio for synthetic oils is 50:1 but this too is variable depending on the important factors. Semi-synthetics vary way too much to suggest a "general" ratio for them although they are typically between 30:1 and 40:1. Click here to read all about 2 stroke engine oils and the oil ratio calculator I created. And if you think one ratio is best because it provides sufficient ring sealing then consider the fact that some oils evaporate off hot rings faster than others and so leave less oil on the rings. So a fully synthetic oil at 45:1 is usually as good at ring sealing as a semi-synthetic oil at 35:1 because it's less evaporative (higher flash point temp). PLUG READING Because jetting depends on type of engine cooling, engine compression, and type of riding then the color actually is of little importance. Pros go by the size of clean areas on the piston top near the transfers and boost port, and to be double sure they aren't risking a seizure they also look under the piston crown to make sure there isn't much oil burned black there. Click here to read my full report on this subject.  Hell, decades ago Jennings told everyone you can't read plug color to jet by. [article]  He went on to say that the soot left at the base of the ceramic cone can only tell you if the jetting is too rich, that you can't use that to precisely choose a main jet for the carb. CARBURETOR SIZE Small sizes don't limit flow by their size but they increase the air velocity thru them. How fine the fuel particles become due to the shearing effect of the speeding air around them is determined by carb size. Perfect combustion at peak power RPM is dependent on a number of factors, including fuel particle size. So the smaller the carb is, the lower the RPM is that it benefits. So size is not a question of flow limitation but rather of fuel atomization dependent on air velocity. To read more click here.  Air Screw Adjustment Most of the main carburetor manufacturers do not emphasize a certain number of turns out, but rather emphasize that you try different idle jet sizes to find the one that allows good idling and also good power before 1/2 throttle. So please don't get stuck on "1+1/2 turns". That is as silly as going by plug color for jetting. Click here to read more. This is from the Mikuni VM manual:  BALANCE FACTOR This is not even a method for finding out what is needed. It's just a way to convey to others what to do for the same crank to get your same good results. To prove this I asked a "balance factor expert" what balance factor he'd recommend for a couple different engines, giving him full details. The answers I got back were way off. I knew they were off because these were two engines I had balanced using my crank balance calculator which doesn't use balance factor to find the right balance. [read more] But it does display what the resultant balance factor is, just for reference.  True Engine Size Unknown to most is that the engine size formula for 2 strokes is not for 2 strokes. It comes from 4 strokes and uses the swept volume of the piston. But for a 2 stroke the trapped volume is the combustion volume, and that is what is above the exhaust port. So be careful to not raise the exhaust port much because you are lowering the actual working engine volume which becomes apparent below the pipe powerband as power there will decrease. Yes I know that inside the pipe powerband the return baffle wave increases the trapped volume but we can't easily measure that, but we can measure the area above the exhaust port. An engines purpose is to change fuel into working power. So why don't we size an engine by its working volume of fuel/air, the trapped volume? On a typical engine if you raise the exhaust port for a duration of 200 from a former 180 then you will reduce the trapped volume by 16%. On both 2 and 4 strokes the output power is directly related to the max RPM so don't think to bring that into the conversation. And a 2 stroke can run with and without an expansion chamber so its ability to increase the trapped volume also shouldn't be included in a basic measurement of engine size. True engine size should be directly related to the trapped combustion volume but because it's easier to just use the 4 stroke formula then it isn't.  Reeds vs Piston Port The old GP racers were all piston port engines and were plenty fast but their intake durations were so big that they were hell to start. They always had to be push started, usually by two people. So if the rider ever crashed or stalled then he usually couldn't restart it. That is the main reason they switched to reed valve engines, for that reason and because piston port creates more intake noise which can be annoying on the street. I used the same cylinder for a back-to-back test of these two intake types. The reed valve version had an additional boost port that the piston port version didn't have and it was filled in with JBweld for the piston port version (because its source was at the intake port when for a piston port it should of been at the crankcase). Since piston port engines need leaner jetting (due to a steeper vacuum wave front) I changed the jets and also put a leaner needle in. Some people have tried such comparsons but failed to use different needles. Any way they both had the same climbing power and top speed. So maybe if the piston port also had a boost port then it would of accelerated faster to the top speed. This is my video of the differences between the two intake types: VIDEO  Fuel/Oil Ratios and Gasoline % A fuel/oil ratio of 35/1 results in 97.2% fuel, and 45/1 gives 97.8% fuel wich is only 0.6% more fuel which is insignificant. But if you change from using a pure mineral oil at 25:1 to a pure synthetic oil at 45:1 then the gasoline content changes 1.8% which you might be able to feel if your jetting was already "on the edge" (too lean or too rich). Density Difference A 30/1 ratio with a 0.9 density oil and a gas with 0.75 density yields an average density of 0.755 and with a ratio of 50/1 the density is 0.753 which is a 0.3% difference, hardly anything. Viscosity Difference I tested that with a main jet and idle jet at the bottom of a cup holding gas/oil mix and no matter what ratio I used the time it took to bring the liquid level down to a preset level was the same, meaning the slight change due to the oil wasn't enough to affect the flow rate. Ideal It's best to pick the best oil for your needs and then pick the right ratio for it and then follow the best procedure for jetting. SQUISH BAND Erroneous is the belief the air/fuel in the squish zone burns too late to contribute to power. Trail bikes are often designed with wider squish bands which hold a greater % of the air/fuel in that zone. They wouldn't engineer it to be that way if that increased the % of air/fuel that doesn't contribute to power. Yes it burns later but not too late to contribute to power. And this isn't a question of squish velocity because a 40% surface area squish band and a 60% squish band can both be made to have the same squish velocity. It's just a matter of head/piston clearance. This is What Happens: Having that zone burn later reduces the peak combustion pressure which reduces peak power, but keeps the combustion pressure from dropping off as quickly, effectively increasing the # of degrees the pressure is effective at delivering working power to the piston down stroke. Increasing those degrees of "work" benefits the low and mid RPM power. % Squish Surface Area of Bore The % of squish area needs to be around 60% for engines needing broad powerbands, and between 45 and 50% for engines needing full emphasis on top RPM power. GRAPH Here's a graph showing that at 35 degrees after TDC there is still 66% of peak pressure pushing down the piston and contributing to power. A 125cc with 60% area squish with tight clearance for max squish velocity still has 4.35mm clearance between head and piston at 25 degrees ATDC which is not small enough to restrict the progression of flame into that area. So obviously this area is burning and contributing to power. Notice also how after TDC the squish velocity reverses to suck burning air/fuel from the main bowl into the squish zone. That also speeds up the burning of that air/fuel in the squish zone.  Click here to read more on this topic. Piston Port Causes Rich Jetting Due To Intake Reversion Piston port intakes need smaller jets due to the steep face of the vacuum wave, not being very gradually increasing like with a reed valve. In a piston port engine the crankcase vacuum starts when the rising piston closes the transfers and then about 50 degrees later, when plenty of vacuum exists in the crankcase, the intake port opens. A reed valve starts intake flow with the slightest of vacuum as the piston rises from BDC. In my 48cc, converting from piston port to reed valve, the main jet area had to be increased from 0.3 sq mm to 0.5 sq mm. Carb flow normally is driven by vacuum which aids in pulling up fuel thru the jets, but when the intake flow reverses it is driven by pressure which can push mixture back down thru the jets. Yes, some of the air that already has fuel mist in it goes past the needle jet 2 times but the second time follows the pressure pulse that had pushed the fuel back down into the float bowl.So that push/pull equates to no extra fuel flow. If much reversion happens with a reed valve then probably the reeds aren't stiff enough. How Engine Oil Affects Needed Ignition Timing The Test So there's a long street uphill in my town which keeps my air cooled 48cc from reaching top RPM and so I got the idea of adjusting the ignition timing to see which timing gives the best uphill RPM (best power). I have an adjustable CDI of my own design. The result showed a maximum difference of almost 7 degrees between one type and another. This means: 1) When changing engine oil type you need to retest for best timing for best peak power or best powerband. 2) it's possible that the best power can be had by using a fast burn oil with a high RPM engine, and a slow burn oil with a low RPM engine. Engine Oil Types: Fully mineral oil, Synthetic/Mineral blend, Fully synthetic, Synthetic/Castor blend, Fully castor oil. Here's the graph results of 4 main engine oil types (5th one coming soon). Where the blue graph is the highest shows the timing (on horizontal scale) that gave the best power.   What also affects the needed timing is how much dispersant (such as kerosene) is in the engine oil to make it more pourable. More dispersant lowers the engine oil density and makes it more rapidly burning which shifts the graph to the left. So if you have adjusted your timing to what you like best and you then switch type oil then by this info you know to also readjust your timing. For Example: Yamalube is mostly group 2 with 29% group 1, so if you switch from that "all mineral oil" to another type oil such as semi-synthetic then you know to recheck the timing. Click here to access my engine oils page which tells the % of each type oil in each engine oil. Click here toread more on the subject of engine oil combustibility and learn how to find the best ignition timing for your bike and the engine oil you are using. |